4. Transport

The funding received from the CLIMIT programme for research into CO2 transportation has generated significant new knowledge. Industry actors and academic communities have gained a deeper understanding in areas such as corrosion, safety, and measurement, simulation and flow technology.

The transport projects have highlighted several issues that have created the need for further research and development. Although there has been steady growth and activity since 2007, there remains a significant need for further research in CO2 transport, especially the need for more knowledge related to safety, risk reduction and cost-effectiveness.

Since 2007, CLIMIT has supported 66 projects in the transport segment, totalling NOK 388 million.

The development in CO2 transport started with the pipeline transport project led by GEXCON AS, which focused on the modelling of CO2 leaks from pipelines and process plants. The largest project, led by DNV, received NOK 21 million in funding in 2016 and highlighted measures to improve safety and efficiency in CO2 pipelines.

An important area within the CLIMIT portfolio, established in 2008, is measurement, simulation and flow technology, which is currently the largest area of expertise. Projects such as ‘Experimental investigation of selected thermophysical properties of CO2 mixtures relevant to CCS’ were awarded NOK 26 million in funding in 2010. Examples of high-impact projects include further developing software such as OLGA, Ledaflow and Oliasoft, as well as developing measuring instruments such as Cignus Instruments’ CO2 mass flow meter.

Ship transport of CO2 received its first project funding from CLIMIT in 2011, but it was not until 2019 that scope increased within this area. Qualifications in technology and logistics solutions have been in focus, with projects such as the Stella Maris and CO2 logistics ships being led by SINTEF Industry. The objective was achieved here by demonstrating that it is possible, using existing technology, to carry out the described large-scale transport and injection of CO2 as covered by the Stella Maris project. The partners’ technical studies and risk assessments have not identified any technical obstacles to this.

Corrosion became a research area in 2012 and focuses on reactions from impurities in CO2. The scope has increased since 2017, with projects such as ‘Kjeller Dense Phase CO2 Corrosion’ investigating chemical reactions at high phase density. Corrosion and CO2 quality play crucial roles in the entire value chain of capture, transport, and storage, and require further research.

- Pipeline and ship transport of CO2 provide new opportunities for cost-effective solutions.

- Knowledge about corrosion and chemical reactions is essential regarding specifications in CO2 transport.

- Measurement, simulation and instrumentation technology are key to understanding conditions and challenges in the transport segment.

Pipeline and ship transport of CO2 provide new opportunities for cost-effective solutions.

Knowledge about corrosion and chemical reactions is essential regarding specifications in CO2 transport.

For CLIMIT, the transport of CO2 has been a core part of the support and financing of Norwegian CCS projects. The background to this is that a safe and efficient infrastructure is necessary for connecting capture facilities to storage sites. From a CLIMIT perspective, transport of CO2 encompasses everything from compression at capture facilities to well injection at the storage site.

In Norway, several initiatives for the transport of CO2 have been adopted, most notably the Northern Lights project, which is a part of the broader CCS efforts of the Longship project. Northern Lights will transport liquid CO2 from capture facilities in Norway and other European countries by ship and potentially pipelines to storage reservoirs under the seabed in the North Sea. Internationally, there are equivalent projects for establishing CO2 transport infrastructure, both on-shore and off-shore, most of which are in the early phases.

CO2 can be transported in a number of different methods:

- Pipelines: The most common method for continuous and large volumes of CO2 over shorter distances or in areas with dense industrial infrastructure.

- Ship: Used for greater distances or transport between regions when ships provide better flexibility than pipelines.

- Road: Used for shorter distances, or when there are difficulties in establishing pipelines.

Many technologies for the transport of CO2 have matured. For example, ship-based transport is approaching commercialisation, particularly in the Northern Lights project.

- Pipeline transport of CO2: The technological development for pipelines in Norway is focussed on ensuring that CO2 can be transported safely and reliably. Examples of technological developments are pressure control systems, material developments, corrosion resistance and gauges to ensure longevity and safety.

- Ship-based transport of CO2: Norway has contributed to the development of ship technologies that can transport liquid CO2 from capture sites to offshore storage sites. The technology here focuses on the design of low and high-pressure CO2 storage tanks, something which requires specially-designed tanker ships. In addition, there has movement in the development of loading and unloading systems, as well as corrosion resistance, which is critical for ensuring rapid and safe transfer of CO2 between ships and storage facilities.

- Digital technology and monitoring: In Norway, advanced monitoring systems have been developed that provide real-time information on the condition of pipelines and ships. Examples of this are sensors and Internet of Things (IoT) solutions along pipelines and in ships for information on pressure, temperature and leakage. Measurement, simulation and flow techniques are fundamental for digital technology and monitoring.

The technological challenges Norway is facing are related to risk and cost reduction, increased safety, scalability and harmonisation of technology. Further research and development is necessary to make transport more efficient, as well as for ensuring that CO2 transport infrastructure can be upgraded in line with future needs. This also means cooperating with other countries to develop international solutions, especially since many countries will need to export their captured CO2 to Norwegian storage sites.

All in all, Norway is well positioned to lead the technological development of CO2 transport, particularly for pipelines and ship transport, and will likely continue to play a key role in global CCS projects in the future.

The transport of CO2 has been a major aspect of the global efforts to reduce greenhouse gas emissions. International regulations that affect CO2 transport are largely grounded in agreements such as the Paris Agreement, the United Nations Framework Convention on Climate Change (UNFCCC) and other international environmental laws.

Key components of the international regulations:

- The London Protocol: This is an international agreement that regulates the dumping of waste into oceans. Norway has been a driver of amending this protocol so that it allows for carbon storage under the seabed, which is crucial for projects such as Northern Lights, which transports and stores carbon under the North Sea.

- EU directives: The EU has drawn up regulations for carbon transport and storage, including rules for pipelines and safe storage underground. Even though Norway is not a member of the EU, Norway is a part of the European Economic Area (EEA) and follows many of the same rules. The EU’s CCS Directive is therefore important for Norwegian regulation of such projects.

- International Maritime Organization (IMO): IMO is responsible for regulating CO2 transport by ship. Norway is an active participant in the IMO, especially as CO2 can be transported by ship to offshore storage sites.

One of the challenges from a Norwegian perspective is the need to harmonise national and international regulations to ensure that CO2 can be transported effectively across national borders, whether this occurs by pipeline or ship. The national conditions for carbon storage are extremely favourable and can provide Norwegian stakeholders with a technological advantage.

Many projects are in an early phase of commercialisation, especially in Europe. Northern Lights, which is an international project, has garnered great interest from industrial stakeholders in several countries, who are now exploring the option of using Norwegian infrastructure for carbon storage.

Further work on the development of transport of CO2 includes:

- Optimisation of transport technologies: There is a need for further research into efficiency improvements of both pipeline and ship-based solutions. This includes improving compression technologies for CO2 and developing solutions for safe transport.

- Economic sustainability: To make CO2 transport economically viable, costs related to carbon capture and transport must be reduced. CLIMIT will also focus on this in the future through support for research into new technologies and solutions.

- International cooperation: Continued cooperation between countries and regions to build a common CCS infrastructure will be crucial. CLIMIT also has an important role here, particularly through its support for projects involving international partners.

- Scaling: Future work must focus on scaling existing projects so that CO2 transport can handle greater volumes in line with CCS technologies being implemented at greater scope and scale. One development may be that larger regional clusters mutually commit capture and transport.

CLIMIT plays an important role by supporting research and development within CO2 transport, especially when it comes to reducing risk and developing cost-effective solutions. The programmes goals are to enable fullscale CCS infrastructure that can contribute to achieving national and international climate goals. CO2 transport is one of the keys to this. In future projects, focus will continue to put on building the necessary infrastructure to allow for storage of large volumes of CO2 in a safe manner.

Internationally, CLIMIT contributes to promoting cooperation through knowledge dissemination and supporting innovation across national borders.

Corrosion is one of the greatest technological challenges relating to transport in carbon capture and storage (CCS) systems. Failure to properly tackle these challenges could lead to pipelines bursting, leakages and potential environmental catastrophes. CLIMIT supports a range of projects aimed at finding good solutions to challenges related to corrosion.

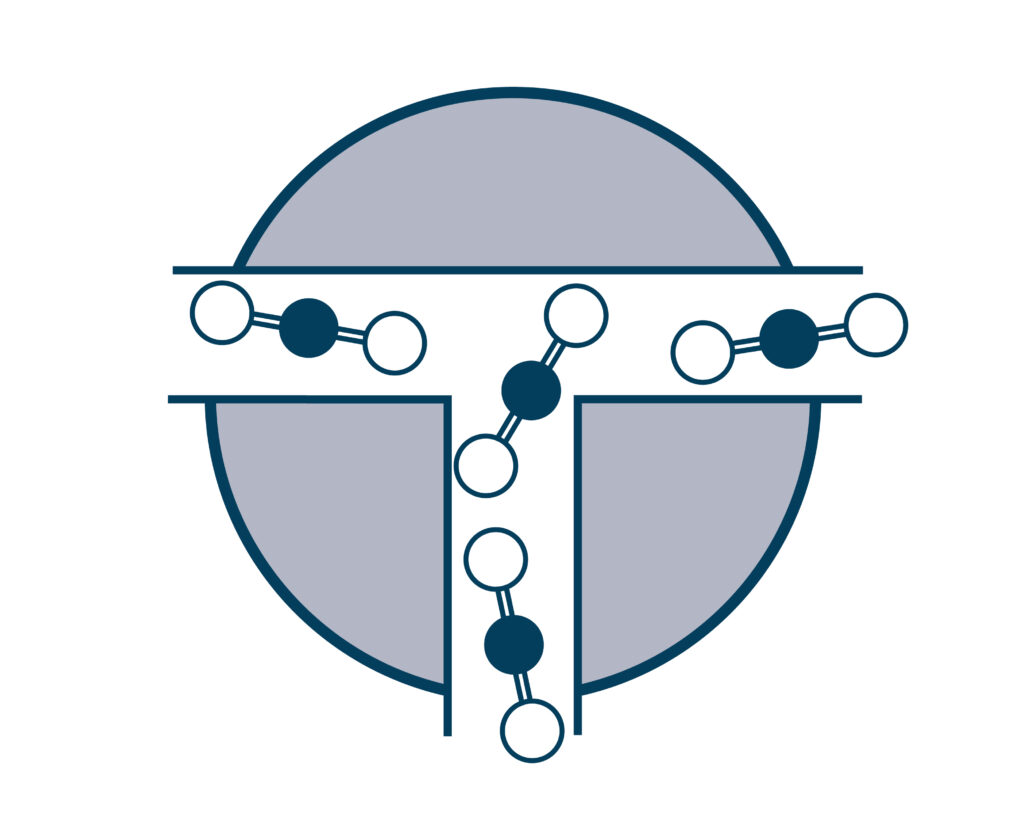

Pipeline transport of CO2 requires thorough analysis of the chemical reactions that can arise when CO2, in combination with impurities such as water, sulphur dioxide (SO2), hydrogen sulphide (H2S) and oxygen (O2), reacts with metals. This article examines the issues, status and further work related to corrosion in CO2 transport, with examples of relevant projects that have been financed by CLIMIT.

The effect of water and impurities on corrosion

Even small quantities of water can, when combined with CO2, lead to the creation of carbonic acid (H2CO3), which is extremely corrosive for the majority of metals. As CO2 flows through pipelines, impurities like sulphur dioxide (SO2), hydrogen sulphide (H2S) and oxygen (O2) exacerbate the corrosion process, in particular at high pressures and temperatures such as those typical of transporting supercritical materials.

Choice of materials for pipes and equipment

The most common materials that are used in pipelines, such as carbon steel, can be vulnerable to corrosion, especially under difficult conditions involving impurities. Alternative materials such as stainless steel and specialised alloys can provide better durability, but they are often far more expensive. The choice of materials must therefore find a balance between cost-effectiveness and durability against corrosion.

Corrosion protection

Different corrosion protection technologies such as coatings, inhibitors and anodal protection have been tested for CO2 transport. Each solution comes with its own challenges related to durability, reliability and cost for large-scale operations.

Monitoring and inspection

Early detection of corrosion is crucial for preventing major damage or leakages in pipelines. Traditional inspection methods must be updated to include the specific challenges that are associated with CO2 transport, including faster rates of corrosion in supercritical CO2 flows.

Many CLIMIT-funded projects have worked to improve understanding of corrosion mechanisms in CO2 transport and developed solutions for tackling challenges:

This project was led by IFE and examined how impurities in dense phase CO2 can lead to corrosion and the formation of solid formations in pipelines used for carbon capture and storage (CCS). When CO2 is captured from industrial processes, it often contains impurities such as water, sulphur oxide (SOX), nitrogen oxide (NOX) and other compounds that can react under high pressure and specific temperature conditions in dense phase CO2. Such reactions can lead to challenges relating to safety and reliability of the CO2 transport infrastructure.

This project is extremely relevant for large-scale CO2 transport projects, where safe and efficient transport of dense phase CO2 is crucial for success. Understanding of how impurities affect corrosion and solid formations will contribute to better design and operation of CO2 infrastructure, something which is essential for ensuring long-term stability and reducing costs. The findings of the project will contribute to strengthening Norway’s technological leadership within CCS.

This project led by IFE and aimed to understand and solve challenges related to corrosion and chemical reactions in pipelines transporting CO2 with impurities. When CO2 is captured from industrial processes for carbon capture and storage (CCS), it can contain impurities such as water, sulphur oxide (SOX), nitrogen oxide (NOX) and other gases. These impurities can lead to corrosion and unintended chemical reactions which can weaken pipelines.

This project is especially relevant for largescale CCS initiatives such as Northern Lights and Longship, where safe and efficient transport of CO2 through pipelines is critical for succeeding in reducing greenhouse gas emissions. The projects results will contribute to improved design and operation of future CO2 transport infrastructure.

This project The project was led by IFE and aimed to research and optimise material selection for safe and efficient transport and injection of CO2 in carbon capture and storage (CCS) projects. When CO2 is transported between pipelines and injected into underground storage reservoirs, challenges can arise related to corrosion, material degradation and mechanical wear and tear, particularly if the CO2 stream contains impurities. The correct material selection is crucial for ensuring long-term operation and minimising the risk of leakages and damage.

The project is extremely relevant for Norwegian CCS initiatives, where reliable transport and injection of CO2 is central to their success. By identifying materials that can withstand corrosion and other stressors over time, the project will contribute to ensuring the safe and efficient operation of CO2 infrastructure. This will support Norway’s position as a leader within CCS technology, while also ensuring sustainable carbon storage solutions.

This research project was led by IFE and examined corrosion in pipelines that transport dense phase CO2, especially in the context of carbon capture and storage (CCS). Transporting dense phase CO2 means that the gas is kept at high pressure, where it is a supercritical fluid. Under such conditions, the presence of impurities such as water, sulphur dioxide (SOX) and nitrogen oxide (NOX) can lead to serious corrosion, which poses a risk to the safety and integrity of pipelines and other infrastructure.

KDC-III is an important part of Norway’s efforts in developing safe and reliable solutions for the transport of CO2 in large-scale CCS projects. The project will provide better insight into how to tackle the technological challenges of corrosion, which will contribute to the long-term and cost-effective operation of CO2 transport infrastructure in Norway and abroad.

This project was headed up by DNV and focuses on challenges related to the presence of hydrogen sulphide (H2S) in CO2 pipelines. When CO2 is captured from industrial sources for carbon capture and storage (CCS), it can contain impurities such as H2S, which can lead to major corrosion and safety risks in pipelines that transport CO2.

This project is relevant for large-scale CCS projects, where CO2 transport through pipelines is crucial. Dealing with impurities such as H2S is critical ensuring the safety and reliability of the CO2 transport chain, the projects findings will contribute to solving technological challenges related to this. This will contribute to strengthening Norway’s role as a leading stakeholder within CCS technology.

This research project is led by IFE and aims to understand and address corrosion-related challenges that arise when CO2 is transported in dense phase in pipelines. Dense phase refers to the state in which CO2 is under high pressure and is a supercritical fluid, which is common for transport in carbon capture and storage (CCS) projects. When CO2 contains impurities such as water, sulphur oxides (SOX) and nitrogen oxide (NOX), it can lead to increased risks of corrosion in pipelines.

The KDC-IV project is particularly relevant for Norwegian CCS projects, where CO2 is transported over long distances and stored under the seabed. Understanding the risk of corrosion and uncovering effective materials and design solutions are crucial for ensuring long-term, safe and reliable operation of CO2 transport infrastructure.

4.3.9 Characterization and Prediction of the CO2 Effect on Polymeric Materials within the CO2 Transport Chain

This project is led by SINTEF and examines how CO2 affects polymeric materials that are used in the CO2 transport chain. This is especially relevant for CCS, where polymeric materials are used in different components such as sealants, packing, coating and pipe components. These materials can be affected by exposure to CO2, especially when CO2 is mixed with impurities from capture processes.

The project is important for ensuring the long-term functionality and safety of the CO2 transport chain, especially when it comes to the choice of materials in critical components used in pipelines and storage facilities in CCS systems such as Longship and Northern Lights.

- Development of more corrosion-resistant materials

There is a need for further research into alloys that are both durable against corrosion and cost-effective for large-scale use. This includes alternative steel alloys and new alloys that can prevent corrosion under extreme conditions. - Corrosion monitoring systems

Development of real-time monitoring systems that can detect corrosion at an early phase is vital for preventing leakages. This will require new sensor and inspection technologies that can detect small changes in the condition of the material before significant damage occurs. - Process Control Optimisation

Further research into how CO2 flows can be regulated to minimise corrosion, for example by controlling pressure and temperature to avoid phase transitions that can accelerate corrosion, will be vital for ensure safe and cost-effective transport systems. - CO2 specification

Further research into the impact of impurities in CO2 flows under different conditions is important for defining a clear CO2 specification through parts and the whole of the value chain.

Corrosion is a central challenge for the transport of CO2 in CCS projects. A range of projects have made important inroads into the understanding of corrosion mechanisms, however further work is necessary to develop robust and financially sustainable solutions. Material development, corrosion monitoring and process control will be crucial areas for future research and innovation.

Efficient transport of CO2 in carbon capture and storage (CCS) requires precise measurement and simulation methods to ensure safety and stability. CO2 in a supercritical condition has specific flow qualities, and small variations in pressure or temperature can lead to phase transitions that affect both the safety and efficiency of the transportation. Understanding and simulating these phenomena is crucial for ensuring the best possible operation of pipelines and ship transport. This article focuses on important issues within measurement and simulation of CO2 flow, with examples from CLIMIT-funded projects.

- Flow dynamics and phase transitions

CO2 acts very differently to other industrial gases when it is transported in a supercritical state. Small changes in pressure or temperature can lead to phase transitions from supercritical fluid to gaseous or solid phases, which can affect pipe integrity or create blockages. - The effect of impurities on flow

Impurities such as sulphur dioxide (SO2), nitrogen (N2) and water can change the density, viscosity and flow qualities of CO2. Understanding how impurities affect the flow of CO2 is necessary for designing pipelines that can transport mixtures of CO2 in a safe manner. - Measurement and monitoring

Being able to monitor pressure, temperature and flow qualities in real-time is crucial for allowing transport to occur safely and efficiently. Traditional measurement technologies must be updated to handle the unique qualities of CO2, especially under dynamic conditions with varying temperatures and pressures. - Numeric simulation

Advanced simulation tools are necessary for modelling how CO2 acts under different transport conditions. Simulations must be able to predict how CO2 will flow through pipelines, and how pressure and temperature will affect the stability of the stream.

Many CLIMIT projects have contributed to the development of measurement and simulation tools for CO2 transport:

This project was led by Petrell and aimed at developing simulation tools that can predict the formation of solid CO2 during transport and storage. This is important for handling safety challenges and ensuring the efficient flow of CO2 in processes involving both pure CO2 and CO2 mixtures.

SolidCO2Sim will contribute to better safety and efficiency in CO2 transport, something which is crucial for the implementation of carbon capture and storage (CCS) at global scale.

This project was led by Equinor and aimed at developing and validating tools that can improve safety and reduce the costs of transporting CO2 in carbon capture and storage (CCS). The project was initiated to meet the need for more precise CO2 transport simulation models, which often require large safety margins due to the uncertainty of current tools and has raised the cost of many CCS projects.

The project has resulted in high-quality data that has been used to improve flow tools.

This project was led by SPT Group Norway AS and aimed at improving the OLGA simulator, a key tool for multi-phase simulation of flows in pipelines with a specific focus on CO2 transport. The aim of the project is to adapt the OLGA simulator to be able to handle the unique challenges of transporting CO2, especially in relation to carbon capture and storage (CCS).

Through this project, OLGA will be able to be just an important a tool for CO2 transport as it already is for the oil and gas industry and contribute to the development of a global CO2 transport system.

This project was led by Schlumberger Information Solution AS and focussed on improving the OLGA simulator, an important tool for modelling multi-phase flows in pipelines. The project aims to make CO2 transport more robust and precise for the safe and efficient implementation of carbon capture and storage (CCS).

Through improvement of numerical solutions, thermodynamic and hydraulic models, OLGA will fulfil the requirements of future CCS projects and ensure long-term technical solutions for CCS.

OLGA CO2 TIDE is led by Schlumberger Information Solution AS and aims to further develop the OLGA simulator for CO2 transport in connection with carbon capture and storage (CCS). The aim is to address many technical challenges by expanding the functionality of OLGA so that it can handle more complex multi-phase transport of CO2 under different conditions.

Through the project, the models of the OLGA simulator have been upgraded and validated by testing experimental data from laboratories and field measurements, which will contribute to future CCS solutions.

This project is led by Ledaflow Technologies DA and aims to further develop the LedaFlow simulation tool to make it more robust and accurate in modelling multi-phase streams related to the transport and injection of CO2. This is crucial for carbon capture and storage (CCS), which is a central technology for reducing greenhouse gas emissions.

Through this work, the CO2Flow project aims to contribute to a safer and more efficient CCS value chain and thus strengthen Norway’s position in climate change technology and achieve national climate goals.

4.4.9 Design, construction and installation of prototype Cignus mass flow meter for CO2 testing at Equinor P-Lab

This project was led by Cignus Instruments AS and focussed primarily on developing more accurate and efficient solutions for mass CO2 flow measurements for future large-scale carbon capture and storage (CCS) facilities.

Cignus’ mass flow meter was tested at the Equinor P-Lab, where the results show that the pressure drop of the meter was 1/10th of that in traditional Coriolis meters of an equivalent capacity, while keeping a comparable level of accuracy. The road ahead includes scaling up to large-scale pilot facilities such as Northern Lights.

This project is led by LedaFlow Technologies DA and focusses on further developing LedaFlow for increased calculation speeds for implementing algorithms to handle phase transitions for pure and mixed CO2 flows. An improved description and accuracy will define phase transitions and allow for greater time improvements. The results are expected to show improved simulation tools that can be used to design safer and more efficient CO2 transport systems, as well as contribute to the development of sustainable solutions by facilitating the secure transport and storage of CO2.

UpLIFT New Solver Phase II – CO2Speed represents and important step in understanding and improve CO2 transport technologies. Through advanced simulation methods and experimental approaches, the project has the potential to contribute to a more sustainable future by handling greenhouse gas emissions in an efficient manner.

The IntoCloud project is led by SINTEF Energi and aims to fill the lacking data and knowledge basis for CO2 leakage at cold temperatures. This will be done through testing tank leakages, dry ice formation in pipes and dispersion tests for starting conditions that have not been studied before. Leakage rates, the effect of dry ice dynamics and dry ice particle size will be measured. These data will be used to develop and validate precise physics models of CO2 leakages, dry ice formation in pipes and CO2 dispersion to surrounding areas. Furthermore, the data will be used to test commercial tools and uncover potential deficiencies. This project will provide the necessary basis for developing accurate calculation tools for the design and risk analysis of CCS facilities.

IntoCloud will facilitate improved safety analyses of CCS infrastructure by generating experimental data and developing a thorough physics-based understanding of CO2 leakages and dispersion to surrounding areas as well as increase knowledge and rigorous measurements of CO2 leakages and the effect of dry ice will help to secure the CCS industry and can thus lead to a safer and more rapid development of CCS internationally.

This project is led by NTNU and aims to establish a thorough understanding of instability in two-phase CO2 flows in pipeline systems. The two-phase flow conditions can result in highly unstable flows that can pose a risk to the integrity of injection wells and the rest of the transport system. This project focuses on establishing a fundamental understanding of the occurrence of two-phase flow instabilities and transient phenomena in CO2 pipeline systems.

The project represents an important step forward in improving CO2 transport technologies. Through thorough research on two-phase flows, it will be possible to develop safer and more efficient solutions for carbon capture and storage, which essential for combating climate change.

This project is led by SINTEF Energi, where studies were carried out of monitoring and control systems for carbon capture and storage (CCS) networks. It is expected that CCS clusters will consist of various CO2 sources with great variation in flow speeds, operational conditions and impurities. This scenario poses a challenge to transport companies and prevents the reliable flow of CO2 to permanent storage sites. The aim is to improve the efficiency and safety of the transport and storage of CO2 by implementing advanced technologies for monitoring and control.

The project represents an important step in improving CCS technologies. This will not just contribute to increased safety, but also to more cost-effective and sustainable approaches to large-scale CCS from industrial sources.

- Improving measurement techniques: Development of more precise and reliable sensors for monitoring CO2 levels and flow qualities in real-time.

- Simulation models: Further development of numeric models to better predict the flow and transport of CO2 under different conditions, including variations in pressure and temperature.

- Experimental studies: Carrying out laboratory and field studies for validating simulation results and understanding the dynamics of CO2 transportation better.

- Regulatory frameworks: Cooperating with authorities to develop standards and guidelines that support safe and efficient CO2 transportation.

Measurement, simulation and flow techniques play a vital role in the development of efficient CO2 transport solutions. Through continuous research and development, we can improve the technologies necessary for handling greenhouse gas emissions. This will not just contribute to reducing environmental impacts, but also promote sustainable solutions that are vital for future energy systems.

Transport of CO2 from capture facilities to storage sites is a critical component of carbon capture and storage (CCS). With large quantities of CO2 needing to be transported over long distances, both pipeline and ship transport are essential technologies for facilitating efficient CCS infrastructure. This is the theme of a number of projects supported by CLIMIT.

Pipelines are generally preferred for transport over land and short distances offshore while ship-based transport provides greater flexibility over longer distances, especially for transport between countries and over national borders. The choice of transport technology depends on a number of factors, including costs, volume, safety and technical requirements. This article examines the challenges, status and further development of pipeline and ship transport for CCS, with particular focus on CLIMIT-funded projects.

In the United States, CO2 has been transported by pipeline since the 1970s for use in enhanced oil recovery, which has shown that pipeline transport is safe and stable over longer distances. At the same time, Norwegian companies such as Yara transported liquid CO2 by ship to countries around the North Sea.

For the transport of CO2, the interaction between purity requirements, transport volume and distance are a major precondition. Pollutants in CO2 from capture facilities related to industry and energy production can affect both operational safety and finances, making more research into safety and regulations necessary.

Choice of technology: Pipelines vs. ship-based transport

Pipelines are preferred for continuous transportation of CO2 from capture facilities to storage sites. They provide an effective solution for large volumes and short-to-medium distances, especially over land. Offshore pipelines require extensive infrastructure and precise monitoring to ensure the safe transport of supercritical CO2. The construction of pipelines can, however, be expensive, especially in challenging geographic areas, such as deep sea or fjord areas.

Ship transport provides a more flexible solution for CO2 transport over long distances, especially when capture facilities are far from storage sites, or when transport needs to take place between countries. Ships make it possible to collect CO2 from many facilities and transport it to a common storage site. One of the technical challenges of ship transport is the compression and cooling of CO2 to ensure that it can be transported in liquid form, which requires advanced cooling systems and specialised storage tanks. The logistics of loading and unloading of CO2 is also complex, particularly when it comes to handling large volumes in a cost-effective manner.

Pipelines are the most cost-effective method for the transport of large amounts of CO2 over long distances, especially when it comes to medium-to-high volumes.

Choice of materials and safety

Pipelines carrying CO2 must be able to withstand extreme conditions, including corrosion caused by impurities in the CO2 flow such as water, SO2 and H2S. The choice of materials such as carbon steel, stainless steel or special alloys is crucial for preventing corrosion and cracks that might result in a leakage. There is also a need for comprehensive safety monitoring to detect small leakages or fatigue before they lead to large incidents.

Experience with pipeline transport for EOR in the United States is not necessarily transferable to Norwegian circumstances, especially since CO2 from industrial capture facilities can contain impurities that can lead to operational disruptions and potential damage to pipelines. Ongoing research and standardisation are crucial for understanding the thermophysical properties of CO2.

Regulation and legal framework

The international transport of CO2, especially by ship, requires a clear legal framework that regulates cross-border transport. There must be concordance between national laws, international conventions (such as MARPOL) and other relevant agreements to ensure that the transportation of CO2 can take place safely and without legal hindrances. Harmonisation of rules and standards is also important for ensuring equal conditions for stakeholders operating in different countries.

Costs and economics

Cost-effectiveness are an important factor for the choice of transport solution. Pipelines require major investment in infrastructure, but provide lower operating costs for the continuous transportation of large volumes of CO2. Ship-based transport requires less investment in infrastructure, but the operating costs can be higher, especially when handling CO2 at low temperatures and under compression for transport. The economic aspect of each CCS project must factor in the distance between capture and storage facility, CO2 volume and available alternatives.

Many CLIMIT-funded projects have contributed to the development of both pipeline and ship-based transport solutions for CO2. Here are some of the most relevant projects:

CO2los IV is led by Brevik Engineering AS and focuses on developing improved logistics solutions for the transport of CO2 by ship. This project builds further on previous initiatives, CO2los II (2018-2020) and CO2los III (2021-2023), and aims to reduce costs and uncertainty related to the transport of CO2. This is crucial for promoting carbon capture and storage (CCS) as an effective method for reducing greenhouse gas emissions.

CO2los IV represents an important step in optimising the transport of CO2 by ship and has the potential to contribute to a more sustainable future by reducing costs and improving CCS safety.

This project was led by Altera Infrastructure and focuses on developing effective solutions for the transport, storage and injection of CO2 in offshore storage formations. It has aimed to verify feasible technical solutions and a cost estimate for large-scale shuttle transport, offshore loading, temporary storage and continuous injection of liquid CO2 for permanent storage.

The project hoped to identify cost-effective and technically feasible solutions for large-scale CCS.

Stella Maris represents an important step in developing effective and sustainable CCS. The project has shown that it is possible to implement cost-effective methods for the transport and injection of CO2.

This project was led by DNV AS and aimed to qualify technologies for low-pressure CO2 transport by ship. The purpose was to prove the technical feasibility of a low-pressure CO2 transport ship concept, reduce risks and remove uncertainty related to their design, construction and operation, as described in DNV-RP-A203. This is an important part of the ongoing development of carbon capture and storage (CCS) that is vital for reducing greenhouse gas emissions and combating climate change.

The project represents a major step forward in the development of effective solutions for ship-based CO2 transport Through qualification of low-pressure technology, it is possible to facilitate a more sustainable and cost-effective CCS approach.

PCO2 DEMO was led by Knutsen NYK Carbon Carriers AS and was a comprehensive effort to develop and qualify technology for the transport of liquid CO2 under high pressure. This project is critical for supporting carbon capture and storage (CCS) by improving the methods for the safe and efficient transport of CO2, which is vital for reducing greenhouse gas emissions.

PCO2 DEMO represents a step forward in the development of safe and efficient solutions for CO2 transportation. Through qualification of EP technology and experimental testing, the project contributes to promoting CCS technologies that are necessary for reducing greenhouse gas emissions and achieving global climate goals.

This project is led by SINTEF Energi and aimed at developing key models and experimental data to support the optimisation of CO2 transport by ship and offshore injection. This is crucial for realising large-scale carbon capture and storage (CCS) projects, which is a part of Norway’s efforts to reduce greenhouse gas emissions.

The CO2FFER project, which is running from 2023 to 2026, will contribute to realising concepts for safe and cost-effective maritime CCS, which will support the expansion of projects such as Longship and other future CCS initiatives.

- Infrastructure scaling

To meet the needs of future CCS projects to transport CO2, pipeline infrastructure, both on and offshore, must be expanded considerably. There will be a need for further investment in technologies that improve cost-effectiveness, including new materials and advanced safety systems that can detect and prevent leakages in real-time. - Development of ship-based transport

Ship-based transport of CO2 is in its early phases, and further research is necessary to scale up this technology for commercial use. This includes the further development of cooling technologies related to CO2, optimisation of ship design and logistics around the transport of large amounts of CO2 in a safe and cost-effective manner. It will also be important to further develop technologies that ensure that CO2 can be handled safely during loading and unloading and that there is sufficient maritime infrastructure to handle large volumes of liquid CO2. - Integration of pipeline and ship transportation

Future projects will require seamless integration between pipelines and ship transportation. This involves developing and establishing CO2 transport nodes, where ships can deliver CO2 to central storage facilities, and where pipelines takeover the transport to storage sites. This can contribute to making CO2 transportation more flexible and economical, while also allowing for a more distributed CCS infrastructure. - Safety and environmental considerations

Going forward, work on improving safety and environmental protections will be carried out, especially with regards to ship-based transport. The development of better safety systems to prevent and manage leakages to the ocean, as well as technologies that minimise the environmental impact of any incidents, will be vital for winning broad international acceptance of maritime CO2 transport.

Pipeline and ship-based transport of CO2 plays a vital role in realising large-scale CCS projects. Pipelines are ideal for transport over short-to-medium distances, while ship-based transport provides flexibility for longer distances and between storage sites in different countries. Developments in both pipeline and ship-based transport has come a long way, particularly thanks to CLIMIT-funded projects such as Northern Lights. However, there is still a need for further development of technology, infrastructure and safety systems.