8. Industrial Clusters

Point source emissions in the processing industry account for one fifth of carbon emissions in Norway. CLIMIT has provided extensive support to projects for collaboration in industrial clusters to find a solution to this major challenge – efforts that have yielded good results.

Decarbonisation of industrial and energy resources is one of CLIMIT’s three focus areas. In Norway, Heidelberg Materials (formerly Norcem) in Brevik has been a front-runner within the industry with major point source emissions. The scientific basis for establishing a carbon capture facility was based on several CLIMIT-supported projects and a dedicated test centre, which tested different capture technologies under real-world conditions on waste gases from the cement factory in Brevik. Heidelberg Materials was then able to take the decision to implement fullscale carbon capture. This was the start of Longship, which quickly saw Hafslund Celsio (formerly Fortum) sign on for carbon capture at the energy recovery plant at Klemetsrud.

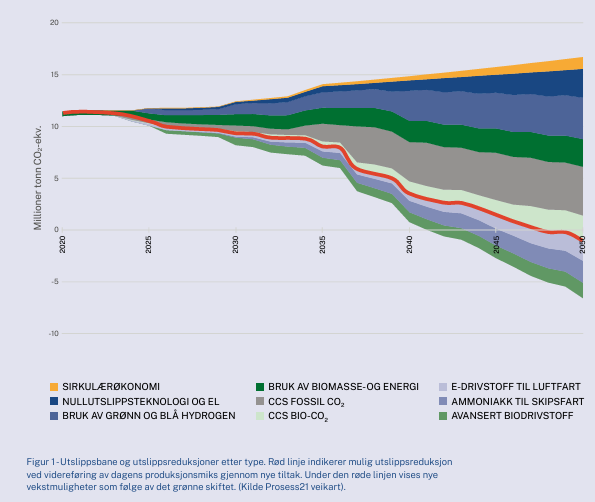

Through the decision on Longship, a demonstration project for a fullscale CCS value chain in Norway, greater momentum was built around CCS in the industry in Norway. This has been important industrial actors that have no clear pathway to decarbonisation by 2050 without CCS. This was also clearly shown through Prosess21 in 2020, where the processing industry collaborated to produce a roadmap to 2050, cf. prosess21_rapport_hovedrapport_web_oppdatert_060821.pdf.

The largest point source emissions in the processing industry see emissions of 9.9 million tons of CO2 equivalents, which accounts for 21 percent of Norwegian emissions, cf. Prosess21, 241010-industribeskrivelse-2024-m-forside.pdf

Industry emissions from the processing industry and the waste incineration/energy recovery industry represents on of the largest point source emissions in Norway. Many of these are the largest point source emissions in their regions (cities/municipalities/county municipalities).

Generally speaking, the industry has lots of expertise in the production of its own products, but little knowledge and expertise in carbon capture. CLIMIT understands this and early-phase feasibility studies provided an opportunity to apply for support to investigate carbon capture at their own facilities.

In 2018, the Eyde Cluster understood the advantage of gathering industry together in Agder to discuss a common challenge: CCS. Much of the industry in Norway is represented by this cluster, including aluminium (Alcoa), ferrosilicon/silicon (Elkem), ferromanganese (Eramet), waste incineration (Returkraft) and silicon carbide (Fiven). This led to other areas with this type of industry also starting joint investigations into carbon capture and shared intermediate storage sites, local infrastructure and transport to storage sites at their facilities elsewhere in Norway. The first clusters were the CCS Eyde Cluster, CO2-hub Nord, the Øra Cluster/Borg CO2 and CCS Midt-Norge, then later Grenland Industrial CCS (GICCS) in 2021 and CCS Haugalandet in 2022.

Working in clusters alongside separate feasibility studies supported by CLIMIT at participants’ factories has led to many industrial stakeholders having gained a sufficient knowledge basis to apply for support for more detailed studies at ENOVA. Examples of this are Erament, which has been/is engaged in multiple clusters: the Eyde Cluster, CCS Haugalandet and Grenland Industrial CCS, Elkem and Ferroglobe (part of the CO2-hub Nord) and Statkraft Varme as leader of CCS Midt-Norge, cf.

- https://kommunikasjon.ntb.no/pressemelding/17961810/eramet-norway-far-132-millioner-kroner-til-energi–og-klimaprosjekter-i-sauda?publisherId=17848299

- https://www.elkem.com/no/investor/announcements/announcement/?itemid=CEB799FA3E5A68E6

- https://<www.enova.no/om-enova/om-organisasjonen/teknologiportefoljen/utredningsprosjekt-karbonfangst-i-trondheim/

“The support from CLIMIT has been crucial for the development of the knowledge basis in industrial clusters for common solutions for carbon capture, transport and storage. At Prosess21, we are now working purposefully to build momentum behind these measures so that greenhouse gas emissions in the processing industry can be reduced further, and we can specialise products that contribute to the sector’s sustainable economic development,” says Maltby. He adds that Prosess21 and the major individual stakeholders (Erament, Elkem and Hydro) have made progress in creating a better knowledge basis. See: 231103 process21ccs-note-updated.pdf”

Lars Petter Maltby was the former CTO of the Eyde Cluster and is now Director of Prosess21.In connection with early-phase learning and knowledge development in industry and clusters, SINTEF Industry and SINTEF Energy Research’s expertise in carbon capture and techno-economic feasibility studies have been of great importance. By being demanding customers of SINTEF’s analyses, the industry has built up a large amount knowledge. This has led to the industry in its own projects, many of which are supported by CLIMIT, progressing with its own more detailed feasibility studies at their facilities. Elkem, Erament and waste incineration/energy recovery facilities are good examples of this.

Waste incineration plants in Norway are not regarded as part of the processing industry. However, through CLIMIT-supported clusters/consortia, as well as CCUS Norway, these two have found themselves facing shared challenges in respect of CCS, CCU and CDR.

The largest Norwegian waste incineration plants have also created their own group with their own projects called Klimakur for Avfallsforbrenning i Norge (KAN) (Climate cure for waste incineration in Norway), where they are working to put in place a generic business model for CCS from waste incineration.

In autumn 2024, KAN received a grant from CLIMIT for a third study to further assess opportunities for CDR and carbon credits. The sale of carbon credits could facilitate CCS at waste incineration plants, whose waste gases contain 50% CO2. This may also be interesting for the processing industry, which is replacing fossil fuels with biomass and increasing biogenic emissions in waste gases.

Check KAN – Klimakur for Avfallsforbrenning for information regarding the CCS manual for waste incineration, KAN’s position and other useful information.

CLIMIT has contribute to industry, through collaboration with CCS industrial clusters, separate feasibility studies and pilot testing at their own facilities developing knowledge about carbon capture at their own facilities. A target has also been set to have CCS at multiple Norwegian facilities by 2030-2035.

Through the CLIMIT-supported cluster projects, the industry has gained a common arena for:

- an overview of the costs of CCS at their own facilities in relation to other industries

- cooperating on joint infrastructure solutions as well as promoting transport and storage companies. This can reduce costs and risks when implementing CCS

- jointly discussing which framework conditions and incentives should be in place to ensure CCS at Norwegian industrial facilities

- learning and knowledge sharing around challenges and opportunities for CCS. Sharing knowledge and learning is easier for waste gases that are not directly related to proprietary processing technology for the production and sale of products