KNCC is a joint venture between Knutsen Group and NYK Group. They transport liquid CO2 (LCO2) to CO2 storage facilities using decades of experience, purpose-built barges, and their proprietary LCO2-EP technology.

The Research Council of Norway; CLIMIT will be even more important in 2024

We need to ensure that researchers are not isolated in their laboratories. Instead, they should engage in dialogue with industry. To promote good and cost-effective climate solutions,” says Aage Stangeland from the Research Council of Norway.

He adds that CLIMIT has an important role to play in ensuring that more emission sources can be linked to CCS projects such as Longship.

The start of a new year

– The climate issue is, of course, very topical. As a result, both the Research Council of Norway and Gassnova have a portfolio of interesting research and development projects. Many of these will be relevant to future large-scale CCS projects. Which supports the benefits realisation goals in Longship.

Aage also highlights the collaboration between Enova, Innovation Norway, Gassnova and the Research Council of Norway in developing industrial carbon capture through PILOT-E. The call is for projects that develop and qualify technologies and solutions. So that carbon capture can be used by 2030. – Close and good cooperation with other public funding organisations will be even more important in the future. This will ensure that government investment has the best possible overall impact. For this to happen, the technology must add value.

Read also the interview with Kari-Lise Rørvik, Head of the CLIMIT Secretariat “CLIMIT; looking back at 2023 and a peek forward”.

The eye of the needle gets narrower

A few months before the New Year, all project funds in both CLIMIT R&D and CLIMIT Demo had been allocated, which brings Aage to the cuts in the government budget in recent years. – With a few exceptions, our research and development work has received less and less funding for new projects. Of course, we must deal with this. At the same time, it inevitably means that the CLIMIT programme must be given higher priority. This means that fewer organisations receive project funding than we would have liked. We get a lot of exciting projects that we unfortunately must de-prioritise.

Aage believes it is important that CLIMIT’s contribution to CCS projects becomes increasingly clear and visible. “This is also in line with the government’s expectations of the CLIMIT programme. – Everything from the development of amine technologies and membrane capture to new concepts for monitoring CO2 storage facilities are examples of projects to which we have contributed. Much of what we are involved in are future capture technologies and new CO2 storage facilities that could be operational in a few years’ time.

International cooperation of great importance

Aage believes that we saw the results of this international orientation during the CLIMIT Summit almost a year ago, when international representatives were present both on stage and in the audience. – The success of the CLIMIT Summit is an excellent symbol of the good partnership and cooperation between Gassnova and the Research Council of Norway. This gives us important momentum for the future CLIMIT collaboration, which started back in 2005.

– I must also highlight the exciting international cooperation we are involved in, including the Clean Energy Transition Partnership (CETP). CETP’s first call for proposals resulted in 10 new projects, several of which had Norwegian partners. It will be exciting to follow these up.

The fact that Norwegian and international research centers work together and create value together is something we want to develop further. The CLIMIT secretariat is also working with the US Department of Energy (DOE), and we had a fruitful bilateral meeting last autumn. US is a very important actor in the CCS context. The deployment of this environmental technology in the US will have a significant positive impact on the global climate. The exchange of experience and knowledge between Norway and the US benefits both countries.

Good dialogue with industry will be important in 2024

– For CLIMIT’s part, we should ideally have linked several projects to the realisation of Longship’s benefits. We are totally dependent on being on the same team as industry. Without interaction with the industry, we can forget about achieving any climate targets at all. When we celebrate the New Year 2024, we should also be able to look back on an even more fruitful cooperation with CETP and other international players, in addition to the rest of the public policy instruments in this country.

– A genuine desire for cooperation between different professional environments, nationally and internationally, will be key to the progress we want to see in 2024. We at CLIMIT have been doing this for almost 20 years,” concludes Aage Stangeland.

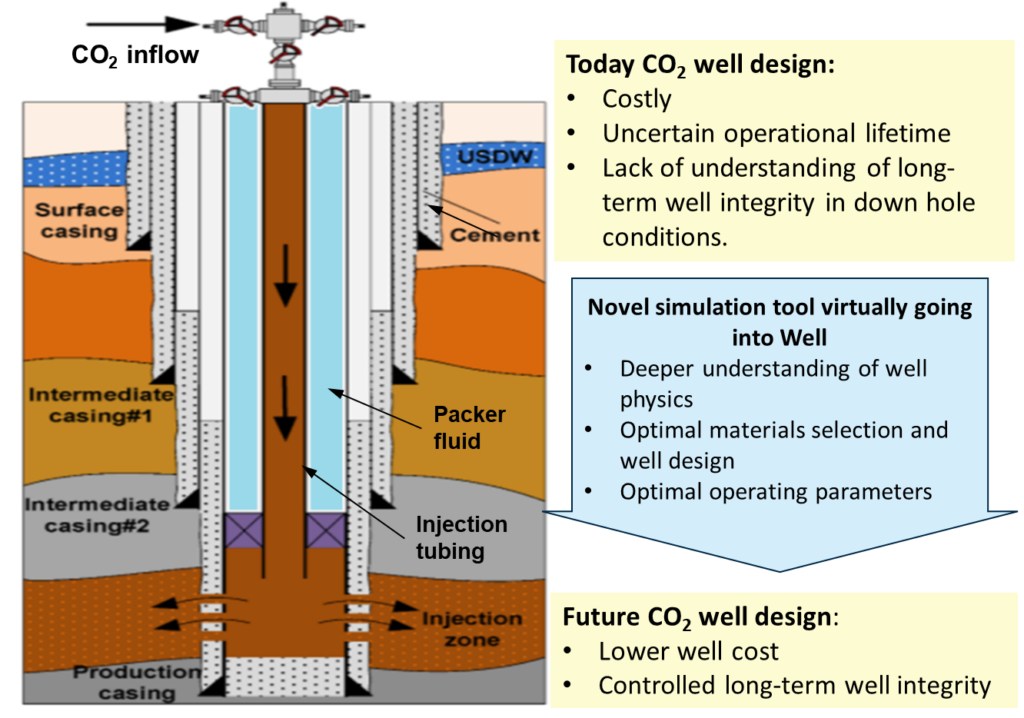

IntoWell: Making CO₂ storage more affordable and resilient

The IntoWell project will investigate and evaluate concepts for future CO2 injection wells. The aim is to make them more robust and less expensive than today.

IntoWell is supported by NOK 6 million from the Research Council of Norway and the CLIMIT program.

Reliable well design and acceptable costs

Following Longship, several hundred new CO2 injection wells are planned for the coming years. A sound CO2 storage project requires innovation to develop a reliable well design. As a result within acceptable cost limits. Operational parameters must be controlled to ensure the well integrity during injection of CO2 batches into the reservoir, and maximize the well lifetime for a favorable return on investment.

IntoWell is a collaboration between SINTEF and Equinor. Moreover the project will develop and validate multi-physics simulation tools for the mechanical integrity of the CO2 well. This will contribute to a reliable design with optimized construction materials, operating parameters, and risk management strategies. The research and innovations of the IntoWell project are at the international forefront. The generated knowledge is important, enabling safe and cost-effective implementation of underground carbon storage and thus contributing to the achievement of international climate targets.

Well concept development

The primary output of IntoWell is the ‘toolbox’ that supports the cost-effective development of well concepts, minimizes uncertainty and ensures the long-term integrity of CO2 injection wells.

This includes:

- An experimental database of well material properties

- A better understanding of the behavior of materials in the well over the relevant temperature range

- Multi-physics simulation tool for assessing the mechanical integrity of the well and optimizing injection strategy

More cost-effective CO2 storage solutions – IntoWell

“CLIMIT’s support has been crucial for the IntoWell project,” says Hieu Nguyen Hoang, Senior Scientist and project manager at SINTEF Industry. – This backing has strengthened our research and innovation efforts in CO2 storage technology. The contributions from CLIMIT have enabled the development of advanced simulation tools, experimental analysis, and research-based knowledge, paving the path for more robust and cost-effective carbon storage solutions.

“The results of the IntoWell project have been shared through academic publications. That provide in-depth insight into our findings. This knowledge sharing will continue in the future,” continues Hieu Nguyen Hoang.

Today, the IntoWell project has reached important milestones. And is at a stage where the results are being consolidated and integrated into current and future CO2 storage projects. In conclusion, the value created by IntoWell will be applied to real storage projects soon.

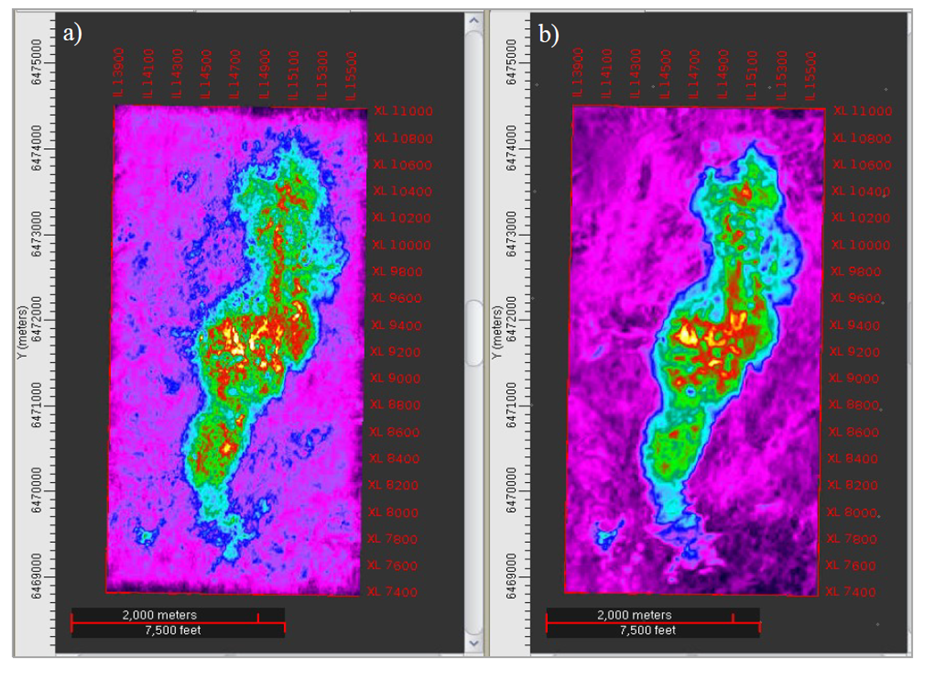

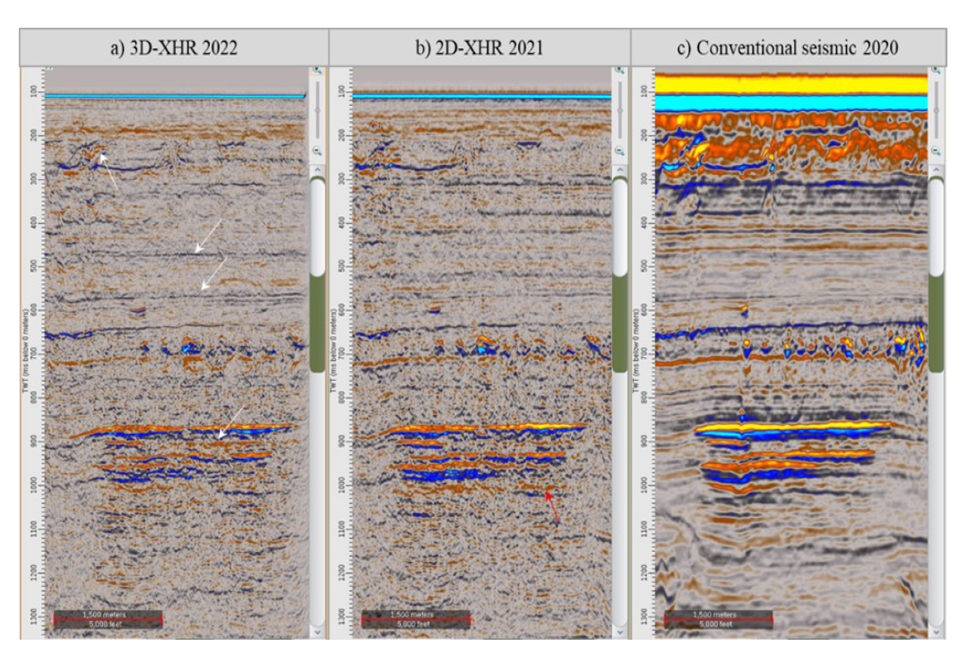

Extended High Resolution: A clearer picture of the underground

The XHR technology makes it easier to acquire high-quality seismic data. At the same time, operational footprint is reduced.

The project is supported with NOK 9.7 million by CLIMIT.

Core to CLIMIT’s main goal

It is the Norwegian seismic company TGS that has developed the Extended High-Resolution technology (XHR), for seismic mapping and monitoring of CO2 reservoirs. This allows detailed imaging of the rocks above the reservoirs (the overburden), in both 3D and 4D format. The technology also enables monitoring of how CO2 moves in the reservoir. – Here we have a project which is core to CLIMIT’s main goal; to help develop technology and reduce costs for users, says Kari-Lise Rørvik, head of CLIMIT.

Success criteria

The driving force behind the XHR project lies in renewing seismic technology – and expertise by offering cost-effective imaging solutions – to the growing CCS industry in Norway, and globally.

Extended High Resolution will contribute to the easier acquisition of high-quality seismic data from CO2 reservoirs. Key expectations for the Technology:

- Improve image quality in overlying rocks that confirm the suitability of the deposit.

- Improve reservoir-level imaging to accurately monitor CO2

- Provide a cost-effective seismic method for CO2

Reduce environmental impact e.g., by improving the utilization of vessels and local equipment.

Testing with Equinor

With a key role in the development of CCS in Norway and Europe, Equinor has shown interest in using the XHR technology. This led to collaboration between TGS and Equinor in 2020 and 2021, where the parties carried out small-scale concept testing of XHR. Promising results led to a full-scale trial of XHR at Sleipner’s CO2 storage in the North Sea, summer of 2022. This was the first time a full-scale XHR collection was demonstrated. Results show that 3D-XHR provides good quality data suitable for CCS monitoring down to a minimum depth of 1,000 metres, which is where the storage reservoir is located at Sleipner. In addition, XHR can be used for monitoring in the event of suspected leakage from deeper storage locations.

Broad exchange of experience

Operational support for the test was led from Magsei’s (now TGS) operational base in Tananger.

The company’s Oslo office was responsible for technical support. Data processing was carried out at Equinor in Stavanger. Overall, strong specialist resources in geophysics and geology contributed, both from TGS and from Equinor’s research and technology group.

Important results from the project

The results from TGS show that 3D XHR provides very good imaging with high resolution, and thus enhanced data quality, compared to more conventional methods – both above and in the reservoir. Tests have also shown that the full-scale XHR can operate with little downtime and is more robust to weather conditions compared to similar systems.

The way forward

Overall, results shows that XHR is a flexible and effective monitoring technology for upcoming CCS projects. – The support from CLIMIT was decisive for us to be able to carry out the XHR demonstration offshore. We now have a rich data set and a combination of XHR and node data which can be used in the further work to demonstrate and implement the technology for the industry nationally and globally, says Tone Holm-Trudeng, Director Offshore Subsurface Solutions at TGS.

One of the mainstays of CLIMIT

On Tuesday 5 December, Eva Halland attended her last Programme Board meeting. After 10 years, she is leaving the research programme where she left a clear direction and hope for Norway’s efforts in CO2 storage.

Research funding outwards

When we ask Eva Halland what she would like to look back on, she is quick to answer: “We have managed to get research results out into the world. We meet an enthusiastic Eva via the Teams screen. “There has been a huge development in CCS over the last ten years. It’s historic.

We have shown that carbon capture and storage (CCS) is possible, efficient, and safe. The CLIMIT programme has gone through several stages. In the beginning, the CLIMIT programme supported technology development and knowledge development in various academic environments. We worked on developing new technologies and reducing costs. More recently, the programme has looked more at the whole and how to build efficient value chains and the details in and around them. When the Longship project was launched in 2021, I thought, yes, this can be done with proven technology. Eva also points out that the Technology Centre Mongstad and international cooperation such as ACT and CETP have helped to strengthen both the Norwegian and international professional community in and around CCS, and CLIMIT has made a difference here, she emphasises.

CLIMIT support has been crucial for the CO2 storage community

“You could say that the Sleipner data has been a paradigm shift. The openness surrounding the data has been crucial to the development we have had both nationally and internationally. It has put Norway on the agenda. The Norwegian Petroleum Directorate‘s CO2 atlas was partly based on the experience of several CLIMIT-supported projects. With CLIMIT’s support, a large environment has also been developed within seismic methods that will be used to monitor CO2 storage facilities. “We can be sure that what we put in does not come out,” says Eva Halland.

If we are to have a long-term approach to CO2 storage, it is important that CLIMIT contributes with research so that we get a lot of good PhDs. It is the young people who will drive the technologies forward, and we need their curiosity and knowledge to create a sustainable future. We must not forget that.

Need for more knowledge

Eva Halland identifies four areas where more research is needed:

- Modelling the CO2 processes in a storage reservoir

What happens when CO2 is injected and stored? - Injection strategy, such as different variants of direct injection from ship to well.

What is most cost effective and safe? - Industry clusters

How to find an efficient way to deal with CO2 from Norwegian industrial clusters. - More cost-effective ways of dealing with CO2

How can CCS concepts create sustainable value chains and business models? How do society need to think about this?

Will see CO2 in the ground

Finally, when we ask Eva where the journey goes next. “I want to see things happen. Even though I will be doing a lot of this in a new way, I still will contribute. Using my experience and developing more efficient processes will be one of the areas I want to work on more. Because it doesn’t stop there!

KNCC: New CO₂ transport technology

The aim of the LCO2-EP project was to qualify the technology for future CO2 transport. KNCC has examined its technology in connection with both conversions and new constructions.

The project is supported by NOK 4.69 million from CLIMIT.

What has been tested?

The project has tested the tank design for Knutsen NYK Carbon Carrier’s (KNCC) LCO2-EP technology on an experimental scale at ResQ’s Safety and Emergency Response Centre close to the city of Haugesund. The LCO2-EP containment system is not a new technology but is based on the already well-documented development of pressurised natural gas (PNG) technology and gas pipeline design.

“Our test rig confirms that CO2 transport at elevated pressure (34 to 45 bar) is ready for deployment,” says Per Lothe, Special Technical Advisor Technology at Knutsen NYK Carbon Carrier. The test rig has also become a unique tool to increase the knowledge of how CO2 behaves at different pressures. The next phase of the project will be to test new CO2 equipment, in our case corrosion monitoring technology, and to investigate how impurities in the CO2 can affect KNCC’s technology.

KNCC’s test rig

The test rig consists of two containers representing two independent CO2 tanks, each containing four pipe sections. The containers replicate a ship installation in scale design. The test program and procedures were developed with the operational needs of a CO2 cargo ship in mind. The test program followed the usual process of preparing a ship’s cargo system for receiving, loading, unloading CO2 and finally preparing for scheduled maintenance.

Solid results in collaboration with qualified partners

In this project, KNCC has collaborated with Equinor, DNV, Horizon Energy and CapeOmega. DNV and CapeOmega, together with the CLIMIT programme, contributed financially.

New ways of organising and implementing CO2 transport are possible and this project has shown that:

- The start-up, gassing and pressurisation of the CO2 was successfully carried out according to the procedures.

- New knowledge about heat transfer between CO2 phases and contact with steel provided important insights for further design and operation, including leak management.

- Minor leaks are easily detected and can be dealt with. Minimal cooling was observed during LCO2 recovery when tank pressure was maintained.

“Having access to a rig with CO2, where we can test equipment and observe adverse events, gives us confidence that the final transport of CO2 is safe,” concludes Per Lothe. The company has ambitions to become a major CO2 transporter in the future. Having a test rig for verification and crew training is important in this context.

Offshore technology behind new CO₂ capture project

CLIMIT visited the University of Southeast Norway (USN) in September to have a look at Moreld Minox’s compact CO2 capture technology.

An idea based on patent from early 1990s

The Minox process was invented by Norlof Henriksen when he was with Norsk Hydro. The process removes oxygen from seawater to avoid corrosion and was patented in the early 90s. This Minox process has since then been in operation at several worldwide offshore oil and gas installations. In 2016, the idea came to develop CO2 capture technology based on the same principles.

Minox saw a changing market and an increasing interest in CCS. With support from the CLIMIT program a concept study was initiated. This was followed by the current project that is testing the technology in USN’s laboratory plant for CO2 capture. The CO2 absorber column has been replaced by Minox’s compact CO2 absorber system that consists of a mixer followed by a gas-liquid separator. The company targets to gain enough knowledge to build a larger facility. – Preferably on an offshore platform where we have previous experience, concludes Tor Skovdal Friis.

We met a dedicated group from Moreld Minox at USN. Left to right: Soudeh Shamshiri, Ole Morten Isdahl, Håkon Helgesen and Tor Skovdal Friis. We look forward to following the project further.

Compact CO2 capture

A well-documented CO2 capture liquid (MEA) is used during the USN test campaign. This enables comparison with reference data. – We want to have an efficient technology, and this must be well documented. We have seen a promising capture rate, and eventually, we look forward to test this out on a larger scale, says Ole Morten Isdahl, who is the project manager for the CO2 capture project and technical manager at Minox. The unique feature with this compact process is the formation of small droplets of CO2 capture liquid that provides large contact area to the surrounding flue gas.

Minox is aiming at a plant sisze of 200,000 tons of CO2 per year and is expecting an absorber height of less than 14 meters and a total area requirements far below current practice. The tests have shown interesting energy performance, and the project is now working on optimization. Minox is satisfied with the capture rate and the effects they have seen at different pressure as well as temperature levels. We are happy to be able to draw on the expertise at USN. It gives us unique comparison and development opportunities – The technology looks promising, emphasizes Ole Morten, who is looking forward to presenting results at several upcoming offshore and CCS conferences.

Facts about the Minox process

The Minox process was developed by Minox and Norsk Hydro’s research center during the years 1985 to 1990. The first unit was delivered to Saga Petroleum’s Snorre A platform in 1991. Today this platform is operated by Equinor. Since then, the process has been continuously improved and optimized and has proven to be a very efficient, robust, and reliable way to deoxygenate seawater. To date, around 30 systems have been delivered worldwide.

Repsol Norge and Moreld Minox, together with the University of Southeast Norway and ProSep, are collaborating on the proof-of-concept of the Minox Compact CO2 capture system. The project will document the absorption and energy efficiency of the liquid-based compact absorber in a pilot scale. A potential application for the technology is CO2 capture in places where conventional solutions are too large and heavy. The target is to optimize the technology for capturing 200,000 tons of CO2/year from offshore gas turbines, but in general the technology is scalable.

Constantly new projects in CLIMIT’s portfolio

The CLIMIT secretariat is constantly updating its project portfolio and we are adding new project reviews.

We share knowledge

“It is important for us to constantly update our project databases,” says manager of the CLIMIT secretariat Kari-Lise Rørvik. We try to post a review of all the projects we support. Which shows the breadth of CLIMIT’s project portfolio. We then build this base out, week by week. We have divided it in two so that there is one for the R&D part, which is under the auspices of the Research Council of Norway. The second part is the Demo part operated by Gassnova SF.

CLIMIT’s project database is available in both Norwegian and English. We have divided it by topic and it should be easy to search around.

An example: Feasibility study Kollsnes SOFC-CC

Alma Clean Power and Gasnor wanted to conduct a feasibility study to assess the effects of producing electricity from waste gas from Gasnor’s LNG plant at Kollsnes, using fuel cell modules with carbon capture. The project is one of those in CLIMIT-Demo’s project portfolio. The fuel cell modules supplied by Alma Clean Power are of the Solid Oxide Fuel Cell (SOFC) type, which can operate with high efficiency on natural gas and with efficient carbon capture (CC). With Northern Lights’ CO2 reception and storage facility on the neighboring site, there is a lot of room for emission cuts. Today, the waste gas is used in gas engines.

The objective of the study was to assess the feasibility and profitability of a SOFC-CC installation. This was to be done by establishing functional requirements, scope and interface for such a development project and making early cost estimates. The effect of increased electricity production and reduced CO2 taxes is considered revenues in the estimates, while the positive effect of heat recovery is neglected. Costs are related to procurement and construction, as well as operation and maintenance costs.

The results are very positive and show that it is possible to improve energy efficiency and reduce CO2 emissions with SOFC-CC technology.

More details about the project

Budget: 0,8 MNOK

CLIMIT Financing: 50%

Project Partners: Gasnor

Project leder: Alma Clean Power AS

Project period: 4/23-10/23

Feel free to contact the secretariat if you have a project idea or have questions about any of the projects you have read about.

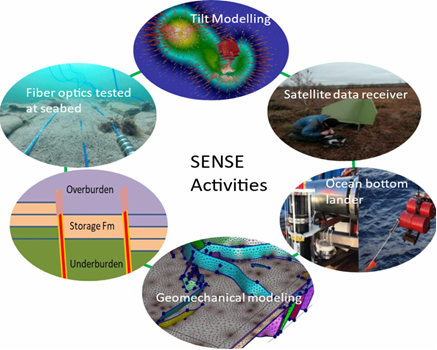

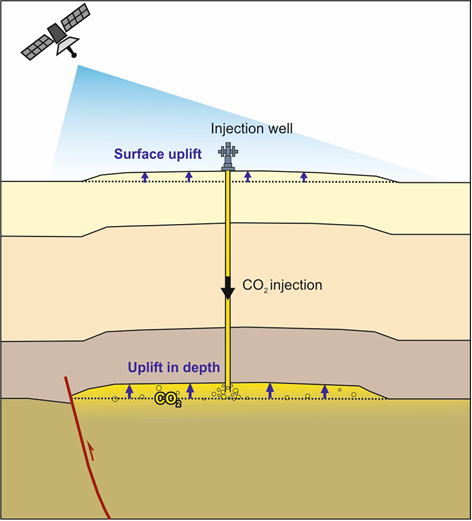

SENSE: Millimeter precision of CO₂ storage monitoring

The SENSE project investigated how new monitoring techniques can contribute to safer CO2 storage. Promising results have emerged which may have international significance.

The project is supported through the international initiative, Accelerating CCS Technologies (ACT), which is part of the ERA NET Cofund. CLIMIT-Demo has contributed funding to the Norwegian research partners.

In the SENSE project, the team has developed a measurement technique that registers ground movements at millimeter level on land and at sea. Ground movement is related to pressure change in the storage reservoir and thus help operators to ensure a safe CO2 injection. Broad international participation with leading research environments and active industry participants has contributed positively to this project, emphasizes Kari-Lise from the CLIMIT programme, which follows several international initiatives under the auspices of ACT.

Three important findings

“SENSE answers important questions about how technological solutions can contribute to safe storage of CO2. We have developed technologies and modeling tools that are more effective than before, says project manager Bahman Bohloli from the Norwegian Geotechnical Institute (NGI). He goes on to say that testing of fiber optics in large-scale laboratory trials at NGI, in Germany and in the field in Japan has helped to confirm and secure the results of the project.

From the laboratory and field tests, we can conclude that “strain-sensing” fiber optic measurement technology shows the same accuracy, and that it is an effective technology for monitoring CO2 storage sites with to get insight on pressure change in reservoir.

Basic data from four areas

The SENSE project has used the following areas to obtain data and concepts for its models, as well as to check hypotheses and confirm the models. We summarize the most important findings per area.

Hatfield Moors (England)

Hatfield Moors is a sandstone reservoir for storing natural gas in the summer and producing the same gas in the winter when demand is high. It is expected that the surface will rise in summer due to the pressure build-up in the reservoir, and lower in winter when pressure in the reservoir is reduced. Satellite data analyzes the connection between pressure changes in the reservoir and movements in the surface. Data from satellite surveillance (InSAR) was used to monitor tiny deformations and movements on land. The SENSE project partner (BGS) introduced an automatic processing method for InSAR data that helps operators reduce costs for detecting surface movements. They also examined and successfully implemented solutions for measuring ground movement through satellite data in a challenging and vegetated marshland.

In Salah CO2 storage in Krechba (Algeria)

In the study by In Salah, post-injection data is used to observe how the surface reacts a few years after the injection has ended. The results show that the ground surface began to sink after the injection stopped. This was expected. The subsidence has a background in pressure drop over time after the injection has ended. The rate of subsidence provides important information about the reservoir’s hydromechanical behavior and thus its modeling.

Boknis Eck offshore in Kiel (Germany)

At Boknis Eck, full-scale experiments are carried out. These measure movements on the seabed that occur due to injection or simulated uplift of the seabed. Here the spotlight is on the precision of the instruments, data interference and other practical issues offshore. Results show that a fiber optic cable can pick up signals from seabed movements with very high accuracy even in a turbulent sea environment near the coast.

Gulf of Mexico (USA)

Here, geological, and geophysical data are used for various scenarios for CO2 injection. Movements on the seabed are then calculated through geomechanically modelling. Collectively, this should provide a basis for choosing technologies for reservoir monitoring. Our conceptual study for the Gulf of Mexico shows which measurement technologies are most relevant for monitoring CO2 storage; strain-sensing fiber optic and pressure sensors are a good starting point.

Plans for the future

The SENSE partners are in dialogue with the industry for the realization of fiber optic measurement technology in large-scale projects. The partners are also in dialogue to develop further solutions focusing on monitoring possible risk of CO2 leakage around faults with the use of satellite data and fiber optic measurement technology.

Key data for the project:

Title: Assuring integrity of CO2 storage sites through ground surface monitoring (619155)

Project owners: Equinor, NGI by project manager Bahman Bohloli, Quad Geometrics and University of Oslo.

The other partners are: GEOMAR (Germany), British Geological Survey (BGS) (UK), IFPEN (France), CIUDEN and Spanish Geological Survey (Spain), Lawrence Livermore National Laboratory and University of Texas, Austin (USA), Research Institute of Innovative Technology for the Earth (Japan), CSIRO (Australia) and KIGAM (South Korea).

Support from the CLIMIT programme: NOK 12.3 million

Project period: 2019 -2022

More information: SENSE and forskning.no

More about carbon capture and storage: CCS, the Langskip project and Technology Center Mongstad

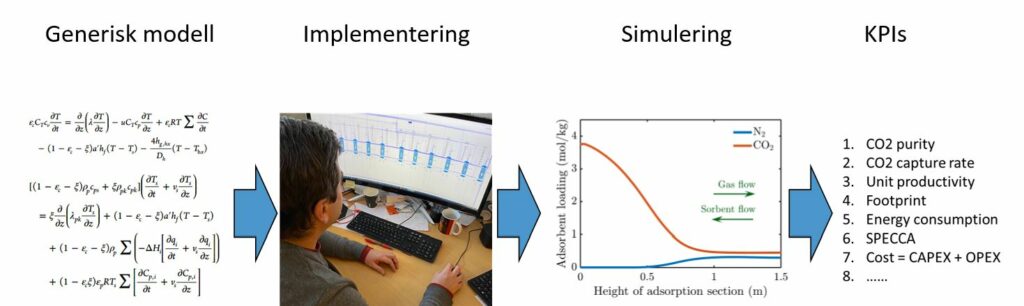

CO₂ adsorption: with the potential to save costs and the climate

CO2 adsorption is a promising technology option for capturing CO2. Some of the benefits can be lower energy consumption, a reduced CO2 footprint and fewer expensive investments.

Adsorption technology is in an early phase when it comes to CO2 capture from industry and has technical challenges that must be resolved. Therefore, a project has been initiated under the auspices of SINTEF Industry and TotalEnergies Norway to simulate the processes. The total budget is NOK 24 million, of which CLIMIT supports half.

What is unique about CO2 adsorption?

Adsorption refers to the process where CO2 molecules are attracted and bound to the surface of a solid substance, such as activated carbon or zeolites. This happens when the CO2 molecules interact with the surface atoms or groups on the solid material through weak chemical bonds. The current most common method of CO2 capture is absorption. There, CO2 from flue gas is dissolved in a suitable liquid. This process usually means that the CO2 molecules also react with components in the liquid. The binding energy for CO2 will therefore be higher in the case of absorption than in the case of adsorption. For both adsorption and absorption, energy must be supplied to release the CO2 molecules again.

What has been achieved?

“In the project, we have worked with 6-7 different processes, and we are working to find the most effective combinations with a number of sorbents (more than the number of amines on the market today). We analyze the sorbents and use the experimental data to simulate how effective and good the various processes will be. The hope is to find combinations that will be better than current amine technology. We already see big differences between the processes when it comes to CO2 footprints”, says Richard Blom, SINTEF. He also mentions that there are big differences in the way in which the processes use the energy. “For example, it is significantly more efficient to move the fixed sorbent between cold and hot sections in the process than to have the sorbent fixed in the column and vary the temperature of the entire column, but one of the prerequisites is that the sorbent can withstand being moved”, emphasizes Richard.

It is also challenging for the project as many of the technologies being tested are at very different TRL levels, which makes the simulations extra demanding and setting up coding that gives comparable results. There will also be local conditions that come into play, such as access to solid sorbent. If it is nearby, the cost picture will be different. The aim of the project is to find an adsorbent/process combination that could eventually be suitable for a pilot on an industrial scale.

CO2 adsorption – improve performance

“Before decisions are made about upscaling, the lab pilots at SINTEF Industry will be used to demonstrate the validity of the simulation results obtained, under different operational constraints”, concludes Svein Gunnar Bekken in CLIMIT. Looking forward to getting the results.

ACT 7: ACT Knowledge Sharing Workshops

The ACT Consortium is holding a two-day event: 7th. ACT Knowledge Sharing Workshop, on 4 and 5, October 2023 in Paris. The focus of the workshop is to share knowledge, experiences and results.

Here you will find the program

Here is the link to register. We hope to see you in Paris.

Knowledge sharing and networking at ACT 7

The ACT Consortium invites the ACT3 and ACT4 projects, ACT partners and all CCUS stakeholders to attend the workshop in Paris. The workshop will also be an excellent opportunity to generate new ideas and build unique networks. Presentations and ambitions of the various ACT projects will also be a source of inspiration.

An international initiative for CCS and CCUS

ACT is an international initiative to facilitate research and innovation in CO2 capture, transport, use and storage (CCUS).

ACT aims to accelerate and mature CCUS technologies by funding transnational research and innovation projects. A total of 16 countries, regions and provinces work together in ACT with the ambition to fund world-class research, development and innovation that can lead to safe and cost-effective CCUS technology.

The history of ACT

ACT started in 2016, and since its inception we have had four calls for tenders and financed 39 projects with €108 million. So far the ACT projects have closed a number of knowledge gaps and delivered results of considerable industrial interest. “We believe this year’s workshop will be another good opportunity to learn and share experiences and further strengthen both networks and expertise,” says Aage Stangeland of the Research Council of Norway/ACT coordinator.

The aim of the Workshop

Aage Stangeland goes on to say: “The workshop’s aim is to ensure knowledge sharing and increase cooperation between ACT-funded projects. Furthermore, we also aim to engage with other CCUS initiatives and stakeholders, and we hope all participants after the workshop are both inspired and full of new ideas.”

There will be presentations from ongoing ACT projects and interactive sessions, including panel discussions and poster sessions over the two days.