CLIMIT R&D: support for three social science projects

CLIMIT’s portfolio is expanding, and new research groups are sharing their knowledge with the “CCS World” within social science related to CCS.

One group, for example, is examining how exporting CO2 to other countries impacts support for CCS and which factors impact public perceptions of CCS projects during construction/planning.

How society responds to CCS

There are three different projects, but what they all have in common is that they look at how society responds to CCS. What is needed in Europe for acceptance of CCS and the market adaptations needed for the roll out of production of blue hydrogen. “We look forward to presenting the results from these three exciting projects,” says Åse Slagtern, special advisor at CLIMIT R&D who promises that we will hear more from these projects in the future.

The three projects

Developing value chains for CO2 storage and blue hydrogen in Europe

- The Ragnar Frisch Centre for Economic Research

- NOK 5.2 million

In order to develop markets for carbon storage and hydrogen, an age-old problem needs to solved: A blue hydrogen producer is not willing to invest in facilities before it has good reason to believe that a carbon storage site is under development. At the same time, an operator considering building a carbon storage facility is unlikely to want to invest before it is reasonably sure that it will get customers.

This project will analyse the development of value chains for carbon storage and hydrogen in Europe. The most important aspects of the project are:

- Assessing the demand for carbon storage, particularly the social acceptance and economic factors for demand for storage services

- Studying the competition between carbon storage in Europe when important factors such as economies of scale and industrial learning are taken into consideration

- Developing business models that ensure an efficient distribution of risk between private and public stakeholders

- Studying the competition between blue and green hydrogen and the competition between conventional energy, CCS-based energy, and renewable energy, and discussing the design of instruments to ensure the socioeconomically favourable development of a value chain for carbon storage and hydrogen

- Assessing how the Norwegian Northern Lights project can change market structures.

As a part of the project one PhD and one postdoctoral will be recruited.

Does the nationality of CO2 matter? Public perceptions of a Northern European market for CO2 storage (CCSMARKET)

- NORCE Norwegian Research Centre AS

- NOK 5.2 million

CCSMARKET analyses what people in Norway, Germany, Denmark, the Netherlands and the United Kingdom think about carbon capture and storage (CCS). A lack of public support, particularly relating to land-based underground storage, has previously been a barrier to establishing CCS in Europe.

Through this project, they hope to discover how exporting CO2 to other countries impacts support for CCS in the exporting nations and how this affects support for CCS in importing nations. NORCE will use comparative surveys to investigate this. The purpose of this is to identify and quantify factors that impact public perceptions of CCS projects during construction/planning. The aim is to improve understanding of mechanisms that impact attitudes towards CCS.

Socio-technical drivers, opportunities, and challenges for large-scale CCUS

- SINTEF AS

- NOK 10, 7 million

This project is based on the multidisciplinary sustainability transitions research field and hopes to understand the innovation processes around the establishment of CCS. The project will analyse innovation linked to the entire value chain for CCS and CCU (carbon capture and utilisation) and will look at how strategies and business models for key industrial operators and regional industrial transformation processes contribute to the development of CCUS and vice versa.

CaptureX focuses on the importance of legitimisation processes (including acceptance) and policy developments for the development and spread of CCUS.

The CaptureX project is being carried out by a leading group of social science energy researchers in Norway (SINTEF Digital, NTNU KULT, UiO TIK) and Sweden (Chalmers) and involves CCS experts from SINTEF Energy.

As a part of the project two postdoctorals will be recruited.

First in-person meeting of CSLF TG with the subsequent international conference on CDR

The CSLF Technical Group (TG) had their first in-person meeting since 2019 in Bergen on 27-29 June 2022.

Global aviation issues and Covid infections meant that many were unable to attend. It still managed three successful days through a hybrid solution.

Three CSLF projects

The Carbon Sequestration Leadership Forum Technical Group, CSLF PIRT (Project Interaction and Review Team) had received applications from three projects that wanted to be recognised as CSLF projects. These were:

- CO2Ment from Canada

- Northern Lights from Norway

- Porthos from the Netherlands

The criteria for being recognised as a CSLF project include the project bringing something new to the implementation of carbon capture and storage. All these new projects do, and all three were recognised. These projects will bring lots of new knowledge that will benefit both countries and stakeholders going forwards.

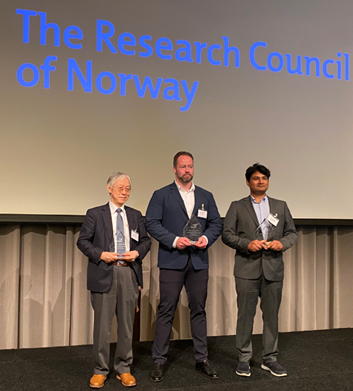

Awards were handed out during the meeting to three CSLF projects that have contributed significantly to the implementation of CCS so far:

- Technology Center Mongstad (TCM) which was CSLF-recognised in London in 2009

- Boundary Dam which was CSLF-recognised in Beijing in 2011

- Tomakomai which was CSLF-recognised in Tokyo in 2016

Two panel discussions were held later in the meeting. The first was led by Bruno Gerrits from Global CCSI and primarily focused on transfer of experience from large-scale pilot projects. Boundary Dam, Tomakomai, Northern Lights, the Heidelberg Materials project and Alberta Carbon Trunk Line had representatives. An important takeaway was the significance of projects being open and reporting on issues that arose and how they were resolved.

The second panel discussion was led by Tim Dixon from IEAGHG and focused on how research and testing infrastructure could contribute to standardisation and scale-up. The International Test Center Network, TCM, CO2Geonet, Otway Research Facility and ECCSEL took part in the discussion. The discussion pointed to the significance of this sort of infrastructure in reducing the risk associated with scale-up and in contributing to standardisation. All participants underlined the challenges in getting funding for infrastructure and operations.

CEMCCUS Initiative, Mission Innovation CDR and the Clean Energy Transition Partnership (CETP) also provided brief updates. All of these initiatives have good synergy with CSLF.

All presentations at the meeting will be made available on the CSLF website

A CDR workshop was held on 28 June

The workshop provided an overview of the policy framework for CDR from the IPCC, the United State’s CDR efforts and the status of Mission Innovation CDR. Furthermore, an introduction to CDR technologies was given with more details on DAC (Direct Air Capture), mineralisation and BECCS (Bioenergy with CCS). Afterwards, several technology suppliers and users spoke about their technologies, before rounding off with a panel discussion on CDR and what the right way to register carbon removal might be. The importance of life-cycle assessments at a system level was brought up. The meeting closed with group work to identify barriers and drivers for CDR.

The IEAGHG will publish a report that summarises the key points from the workshop.

Furthermore, presentations from the CDR workshop will also be made available on the CSLF website 2022 Technical Group Mid-Year Meeting | CSLForum.

Participants were also able to visit Northern Lights on 29 June.

CLIMIT Summit 2023

Save the dates: 7-9 February 2023. See you at the Bølgen Cultural Centre in Larvik.

International synergies

As soon as we return from the summer break, we will start planning next year’s CLIMIT SUMMIT. We hope to see you there, so be sure to save the date in your calendar: 7-9 February. CLIMIT’s programming committee agreed at its meeting in June to organise a summit in 2023, and the secretariat has been tasked with planning this event which will take place over two days from midday to midday.

In 2023 this will take place at the Bølgen Cultural Centre in Larvik. The 2023 edition of the event will focus on the realisation of gains and experiences around the interface of project Longship with ACT, CETP, Mission Innovation, IEAGHG, and CSLF. This will allow us to create positive synergies between a range of CLIMIT projects and international activities. Naturally, CLIMIT’s project portfolio will also be showcased as a key element of the summit. We look forward to seeing you all in Larvik in February 2023.

Please feel free to get in touch with us and our project manager Liv Lønne Dille if you are thinking about tying an event into the wider summit.

For more information

New ACT announcement

The purpose of the call is to support research and innovation that leads to implementation of technology for large-scale carbon capture, utilisation and storage (CCUS).

A secondary goal is to strengthen international cooperation in CCUS.

About the call for proposals

ACT stands for “Accelerating CCS Technologies” and is an international collaboration where funding agencies from several countries collaborate on joint calls for CCUS projects. ACT’s fourth call for proposals, ACT4, will be published in spring 2022 with the deadline 12 September 2022.

Grant applications for the international ACT4 call can be submitted as described on ACT’s website. Norwegian partners who participate in applications for the international ACT4 call must in addition submit an application under this call, which is the Norwegian ACT4 call.

Applications for the Norwegian ACT4 call must only include Norwegian partners and Norwegian activities that form part of a bigger international ACT4 project.

The applications must fall under the topics described in CLIMIT’s work programme.

The Norwegian-language call for proposals is the legally binding version.

CLIMIT support means Preem is ready for CCS

CLIMIT, together with the Swedish authorities, has supported Preem, one of Sweden’s largest CO2 emitters.

The company has two refineries on the west coast of Sweden, one in Lysekil and one in Gothenburg. Preem is exploring the possibility of fullscale CCS using storage in Norway.

Implementation at existing facilities

The primary goal of the project was to research the possibility of implementing fullscale carbon capture from Preem’s hydrogen production unit (HPU) at Preemraff Lysekil in Sweden and to produce liquid CO2 for permanent storage underneath the west coast of Norway in accordance with specifications and requirements set out in the Longship initiative.

SINTEF Energi AS, Equinor Energy AS, Aker Carbon Capture AS and Chalmers University of Technology have all been involved in the project in one way or another, and publications have been and continue to be released and a number of webinars relating to the project have also been held.

Activities completed during the project

- Carbon capture demonstration at the hydrogen production unit at the Preem refinery in Lysekil. The production unit is based on steam methane reforming (SMR). For the demonstration, pilot-scale carbon absorption was tested through the use of Aker Carbon Capture’s mobile testing unit (MTU).

- Extrapolation of the results of the demonstration so that they can be understood in connection with the work on the fullscale implementation of carbon capture from HPUs and other major emissions sources at the Lysekil refinery and Preem’s refinery in Gothenburg.

- In-depth examination of opportunities around energy efficiency in the CCS value chain, including recycling and the use of residual heat at the refinery which can be used to run the process for solvent recovery as well as using alternative solvents for carbon capture.

- Evaluation of the technical feasibility and cost to the CCS value chain, including carbon capture and transport by ship to storage facilities off the west coast of Norway.

- Research into relevant legal and regulatory aspects of carbon transport and storage across borders and national goals for emissions reductions in Norway and Sweden.

Two publications are publicly available:

- D5.1 Preem CCS – Synthesis of main project findings and insights

- Available online in the Chalmers archive: https://research.chalmers.se/publication/528685

- D4.2 Legal and regulatory framework for Swedish/Norwegian CCS cooperation

- Available online in the SINTEF archive: https://hdl.handle.net/11250/2984155

Clean waste incineration

Combustion of waste produces large amounts of CO2 that is emitted directly to the atmosphere. Statkraft’s plant at Heimdal gives off 240 000 tonnes annually.

Currently, the company is heading a feasibility study on how CO2 from incineration can be captured, transported and stored.

Statkraft’s plant at Heimdal incinerate waste from the entire mid-Norway. The district heating plant sends heated water in pipelines to housing associations and institutions such as St. Olav’s Hospital, the Norwegian University of Science and Technology, Lerkendal Stadium and the Nidaros Cathedral.

These days, Statkraft is conducting a feasibility study in cooperation with national and international players, the industrial cluster CCS Mid-Norway, Trondheim Port Authority and Trondheim Municipality.

«The content of the feasibility study is three-fold,» explains Statkraft’s Bjørn Hølaas, director of CCS. «In the technical part, we are evaluating different technologies for capture, and intermediate and permanent storage. In the commercial part, we are analysing how the framework of incentives, markets, sources of income, taxes, etc., is developing. Finally, we are investigating how the growth of the circular economy will reduce fossil content in waste – mainly plastic – since this will cut fossil emissions.»

Mature technology

Statkraft has chosen to divide the feasibility study in two parts. In one part, a technical basic concept was developed in cooperation with Rambøll Denmark, Project Invest and TCM. The second part encompasses verification, improvement and optimisation of the basic concept together with suppliers.

«We have focused on establishing a robust concept,» says Bjørn Hølaas. «Since we selected a standard monoethanolamine (MEA) solution, we don’t have to consider patent issues. The amine technology has been widely proven and is comprehensively documented. We wanted to ensure that the concept was buildable, so that the work in part two – verification, improvement and optimizing the concept – ran smoother.

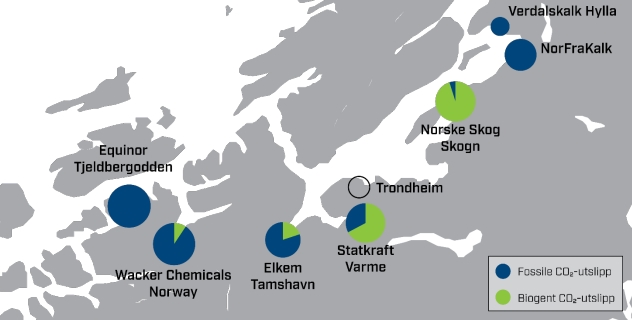

Location of players included in value chains for CO2 transport. Circles are scaled by total CO2 emissions in 2018. Ill. SINTEF / Statkraft

The value of cooperation

One of the main challenges of implementing CCS at the district heating plant at Heimdal, concerns transport and intermediate storage. Still, almost 40 percent of the costs of the basic concept is related to transport, intermediate and permanent storage. And this cost must be reduced.

Whether Statkraft chooses to hook up to the Northern Lights infrastructure – or opts for a different alternative – the company will need an intermediate storage for captured CO2. The basic concept includes an intermediate storage of 3600 tonnes. Which is about half a ship load from Northern Lights.

«As a consequence, we have sought to collaborate with other players in CCS Mid-Norway. If we can work together to identify solutions for transport and intermediate storage in Trøndelag – and this way reduce costs for all of us – implementing solutions for transport and intermediate storage, will be a realistic option,» says Bjørn Hølaas.

CCS Mid-Norway springs from the Mid-Norway industrial cluster. Companies such as Franzefoss, Elkem Thamshavn, Wacker and Equinor at Tjeldbergodden, participate in this initiative, seeking to develop a regional infrastructure for transport and intermediate storage of CO2 from the production processes.

Regulatory framework in process

An important part of the feasibility study is dedicated to developing a comprehensive overview of the commercial framework for CO2. There is great interest in EU’s certification scheme for handling CO2, which will be announced towards the end of 2022.

«EU’s new directive will give us important instructions on how we shall monitor, and report on, critical parameters along the value chain. It’s also interesting to observe how Sweden, Denmark, the Netherlands and Great Britain have organized their CO2 handling regulation regimes.»

Voluntary marketplaces for CO2 quotas and biogenic emissions – like Puro Earth and other arenas – are growing steadily, and will eventually play a decisive role.

«In Statkraft, we see the importance of partnering up with key players – in a broad cooperation with relevant authorities – in order to promote a sustainable framework,» says Bjørn Hølaas.

A robust regulatory framework ensures a level of predictability that is necessary for the industry in order to implement CCS technology. But more is needed from governmental authorities.

«Putting CCS technology to use, is crucial in order to learn from practical and operational experience – which, in turn, translates into cost reductions. In commercial terms, it will take some time before CO2 capture will be economically sustainable, so it’s imperative that governments contribute with public funds.»

CLIMIT support creates results

So, what role has CLIMIT’s played?

«The financial support is definitively crucial. But maybe even more important is it that CLIMIT supports such a wide array of CCS projects. The accumulated knowledge that is channelled through CLIMIT, is as valuable as the support we receive for our own projects. And it’s a great advantage that CLIMIT emphasizes the external communication of project results. Moreover, I believe that for those of us who work in the different industrial companies, public funding through CLIMIT gives the internal projects we propose higher legitimacy,» says Bjørn Hølaas.

The voyage towards carbon capture

Together with partners, Elkem has instigated a project for testing technology that captures CO2 from smelters. This is the first time such technology is applied to flue gas emissions in the ferroalloy industry.

The project draws on a goal-oriented, systematic effort to build competence in the field of carbon capture.

The process industry must play a central role in the struggle to achieve the overarching goal of the Paris agreement: Limiting long-term temperature increase to well below 2℃. A shift from fossil fuels to green energy, will not alone suffice to cut emissions. In fact, many industrial companies produce more CO2 than finished product. Therefore, high costs become the bottle neck for implementing carbon capture plants. This means that the research community and the industry together must find pragmatic solutions that the industry can adopt rapidly.

And one of the drivers behind CCS in the Norweigan process industry is Elkem, one of the world’s leading provider of advanced silicon–based materials.

A necessary collaboration

Bringing about substantial changes requires knowledge in new areas.

«Elkem’s voyage started around 2017,» says Elkem’s climate director Trond Sæterstad. «At that time, Elkem joined CO2 Hub Nord.» This initiative for collaboration on CCS and infrastructure, consists of industrial players in Mo i Rana industrial park and companies further north, as well as in the county of Trøndelag.

Since Elkem has production plants at several locations in Norway, the company has been a proactive contributor in an array of CCUS industrial collaborations – such as the Eyde cluster, the Mid-Norway cluster, in addition to CO2 Hub Nord. The latter is currently starting up tests of CO2 capture from the flue gases of Elkem and SMA Mineral.

In these cluster projects – all of which receives financial support from CLIMIT – the member companies are investigating solutions for CCS, local infrastructure and logistics.

«It’s a huge advantage for adjacent industry to collaborate in order to establish sound solutions for local infrastructure and logistics. That’s why the cluster projects are so important. This way, it’s possible to source large volumes of CO2 for storage, and the companies can share costs related to infrastructure and transport,» says CLIMIT’s Jørild Svalestuen.

A learning process

Elkem has focused on several areas.

Between 2015 and 2019, the company participated in the CLIMIT-supported project CO2stCAP, a cooperation between Norwegian and Swedish industrial companies and research communities. The purpose was to analyze processes and identify factors that drive down costs in carbon capture projects.

Elkem also participated in Process 21, a cooperation and knowledge sharing initiative between Norwegian companies. The forum directed attention toward identifying solutions to reduce the total emission of the national process industry. The steering committee was headed by Håvard Moe, Elkem’s senior vice president for technology.

In 2021, Elkem launched the Global Climate Roadmap. This strategy defines CCS as central to reaching the company’s goal of sustainable production of materials.

A study of opportunities

Through this multi-faceted work, Elkem acquired the competence required to take the next step. The company was ready to investigate practical, operational carbon capture solutions for its smelter plants. In parallel with CO2 Hub Nord, the company executed a feasibility study, which was completed in 2021.

The purpose of the study was to devise a business model for the installation of CCS technology at Elkem’s smelter plants. The model evaluates all critical factors related to operating such technology. By closely considering a diverse set of operating conditions – such as technical status – at the smelter plants, the model calculates with a high level of precision, what it will cost to implement capture installations at the local plants.

Two solvent technologies – from Saipem and Aker Carbon Capture – were evaluated according to the needs of the smelter plants. How could the technologies be adapted to the operational environments? How well suited were they to extract CO2 from the flue gas emitted during the production process?

«It was an incredibly exiting exercise,» says Ragnhild Jensen, project director in Elkem. «We needed to learn more about the practical aspects of CCS. What do we have to do on our side of the interface? How must the plants prepare and facilitate the installation of the new technology? What happens in the capture process? What’s the output? And – not least – what is required in terms of energy integration?»

Elkem brought in Norsk Energy, a consultancy specializing in environmentally friendly and safe use of energy, in order to evaluate the energy integration aspects of the technology from the two suppliers.

«The project gave us a better understanding of the efficiency of capture, the technical requirements that the vendors specified for Elkem’s flue gas, and the output of the technologies,» says Ragnhild Jensen.

The result was a significantly improved process design for the implementation of CCS technology.

One step further

The knowhow that Elkem acquired through meticulous preparations, has been essential in order to carry out comprehensive testing at the smelter plants.

«The natural next step for us, is to verify the technology at our plants,» says Trond Sæterstad, Elkem’s climate director. «Before we can make an investment decision, the capture installations must be tested and evaluated in an operational setting.»

Now, the ferrosilicon producer Elkem is starting up – under the auspices of the CCUS industrial consortium CO2 Hub Nord – the first pilot project of its kind. During six months, the company will operate a mobile test unit from Aker Carbon Capture – a full-scale capture plant in miniature.

The capture technology from Aker Carbon Capture will be tested on separate flue gases from Elkem Rana and SMA Mineral. However, the project will also test CO2-cleaning from jointly sourced flue gas from the two producers.

The last alternative opens up for exciting prospects. The option of gathering streams of flue gas from several producers, will translate into significant cost reduction for each industrial company.

And this is critical. Because it’s imperative to reduce costs.

CO2-hub participants.

Rana-MTU building site.

CCS creates new industries

Hydrogen Mem-Tech recently received NOK 170 million in new capital from major Norwegian and international stakeholders.

But for the Trondheim-based business – a leader in hydrogen technology – it has been a determined route to this milestone.

Investors

On 9 May 2022, it was announced that heavy-weight investors – AP Ventures, Yara Growth Ventures, Shell Ventures, Saudi Aramco Energy Ventures and SINTEF Venture – had chosen to provide significant backing to Hydrogen Mem-Tech. It involves investors with considerable experience and expertise in the hydrogen value chain, and who have high hopes for the hydrogen economy.

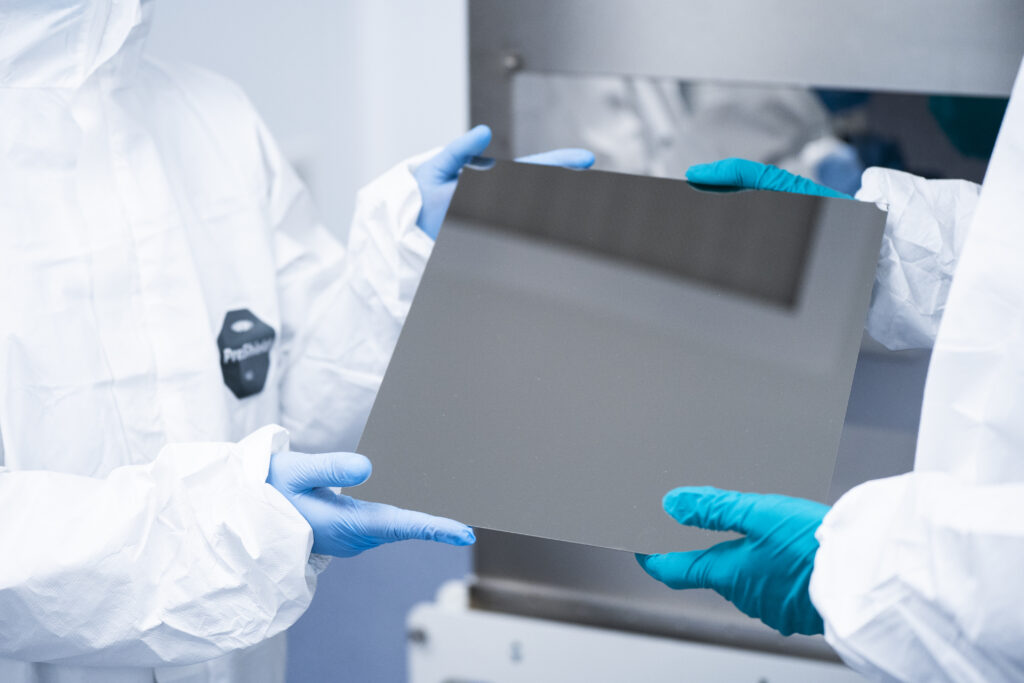

Hydrogen Mem-Tech has worked on further developing a technology involving palladium membranes to filter out hydrogen from natural gas and biogas. CO2 and waste gasses are captured during the process and can then be stored or deposited.

The technology is hitting a market that is seeing strong growth. Hydrogen is viewed as a driver of the green transition.

“Interest in hydrogen has accelerated rapidly in recent years and has opened up lots of markets – far beyond those we might have envisaged as the primary ones when we started out,” says Thomas Reinertsen, CEO of Hydrogen Mem-Tech.

Opportunities in a number of areas are being looked into around replacing other types of fuel with hydrogen, such as for cars, boats, energy generation – and in the processing industry, concepts to replace carbon as a reducing agent with hydrogen are being considered.

The journey to investor interest

Close contact between Hydrogen Mem-Tech and SINTEF created a breeding ground for a business idea. The starting point was looking at alternatives for carbon capture that can contribute to the green transition. SINTEF had developed a competitive and promising Palladium membrane at the laboratory scale which can filter out hydrogen from natural gas, but the research institute was looking for an industrial partner who could further develop and commercialise this technology. Hydrogen Mem-Tech – which drew on extensive experience from the oil and gas industry – was keen on the idea.

And Hydrogen Mem-Tech chose to throw itself in at the deep end. In just a short period of time, they developed the technology from lab-scale to a pilot facility.

“We decided early on to set up a pilot of this technology in an operational environment. And we were given a unique opportunity to build a pilot facility on the grounds of Equinor’s facility at Tjeldbergodden,” explains Reinertsen.

Membrane technology is a good example of successful co-operation between a leading research community and an industrial operator with knowledge about running a processing facility – and how to integrate technology into existing infrastructure.

“There are advantages and disadvantages to testing at large scale early on in the process. But trying it out in the real world early on was clearly crucial for the development of the technology as it stands today,” Reinertsen continues.

Technology in the operational environment

Hydrogen Mem-Tech has focused primarily on making the technology resilient. Our palladium membrane is much thinner than other membranes. It is therefore crucial to create a membrane and a set-up that can handle unforeseen circumstances, such as, for example, power outages and rapid shutdowns. Furthermore, the technology can be installed in both small and large facilities and has low operating costs.

“Our focus on making it more robust has proven to be worth its weight in gold. It means that we have already been able to deliver reliable products while the company is still in its early stages,” says Reinertsen.

Vital support from CLIMIT

Funds from CLIMIT have played an important role in the development of the technology and the company.

“The support we received from CLIMIT back in 2012-2014 turned out to be the ticket to being able to build a technology and a company in exclusively Norwegian hands up to today. It would have been impossible to achieve this without public support from CLIMIT.

It probably wouldn’t have been possible to attract enough private capital to develop this kind of tech company in a long-term perspective. The support we are now seeing from international stakeholders represents a great springboard for Norwegian technology in the wider world.”

Carbon-free power generation – from idea to solution

Industrial gas turbines are used in power plants and as mechanical drives. Today’s industrial gas turbines use fossil fuels such as natural gas or diesel, which causes CO2 emissions in the exhaust gas.

The BIGH2 project develops gas turbines that can use carbon-free fuels that eliminate CO2 emissions. The aim of the project is to develop solutions that enable gas turbines to perform as well with carbon-free fuels as with today’s fossil fuels.

Gas power plants have higher efficiency and significantly lower CO2 emissions than coal-fired power plants, but emissions from gas power plants must nevertheless be reduced to meet climate targets.

“A fundamental idea for BIGH2 has therefore been to facilitate the transition to low carbon fuels”, says project manager Andrea Gruber at SINTEF.

Carbon fuel

Hydrogen is a promising alternative to fossil fuels because combustion of hydrogen gives water vapor (H2O) instead of CO2 as a product in the exhaust gas, but there are also challenges with the use of hydrogen as a fuel:

Hydrogen has low density, so it must be transported under high pressure, or in liquid form at very low temperature.

Higher safety risk because the hydrogen is very explosive (wide flammability range and low ignition temperature).

Combustion of hydrogen results in high flame temperatures that can result in emissions of nitrogen oxides (NOx) that exceed statutory emission limits. NOx is a local pollution that can cause people respiratory problems and cause acid rain.

Controlling combustion is more challenging for hydrogen than for hydrocarbons, and combined with high flame temperatures, it increases the risk of emergency shutdowns and damage to the turbines.

The challenges of hydrogen led the project to choose to study the use of ammonia (NH3) as fuel. Ammonia is produced in large quantities all over the world, including as a raw material for the production of fertilizers, so there is already a well-developed infrastructure for transporting ammonia.

Phase 3 of the BIGH2 project studied the combustion of hydrogen and ammonia in models of combustion chambers of an industrial gas turbine from Siemens. The combustion chamber is the part of a gas turbine where the flame stands.

Ammonia has inferior combustion properties compared to fossil fuels, and must be mixed with more reactive substances to achieve a stable flame. Splitting a share of ammonia fuel into hydrogen and nitrogen results in improved combustion properties of the fuel mixture. Since this splitting is an energy-intensive process, the project has focused on identifying the energy-optimal mixing ratio of ammonia, hydrogen and nitrogen.

“In our process, we use the waste heat from the gas turbine to split ammonia to increase the reactivity of the fuel and at the same time we achieve an increase in the efficiency of the plant. This solution may reduce the costs of different CCS chains”, says Andrea Gruber.

Reduced NOx emissions

One challenge is that the combustion of ammonia-enriched fuels, if not done correctly, can also result in significant emissions of NOX and potent greenhouse gases such as nitrous oxide (N2O). By organizing the combustion at different stages of the combustion chamber, the project has managed to reduce the formation of NOX and N2O to an acceptable level.

Andrea Gruber and his research team worked long office hours before experimental work was carried out in the laboratory. Many small-scale combustion experiments were carried out in SINTEF’s pressurized combustion rig at Gløshaugen to test the flame stability of the various fuel mixtures, and to measure the emissions of NOx. Measurement data from the experiments were then used in numerical simulation software to model flames of various compositions of ammonia, hydrogen and nitrogen. Data was exchanged with partners at NTNU in Trondheim and with Sandia National Laboratories in the USA.

“The most important result from the project is that we have now seen that it is possible to use ammonia as an energy carrier – no major obstacles have been found. BIGH2 has shown us how this can be done. We didn’t have that knowledge when the project started,” says Andrea Gruber.

Broad collaboration

SINTEF worked with NTNU, Siemens and Equinor as partners in the project, while Sandia National Laboratories (USA) and the University of California, San Diego were involved as external partners.

Future plans

“Future work will focus on the development and demonstration of a modified DLE (dry low emission) burner and combustion chamber. We now know that this can be done but we must find the optimal way to implement the solution in a gas turbine. The main goal is to achieve fuel flexibility, i.e. to create a gas turbine that can seamlessly transition between natural gas firing and the application of an optimized ammonia-based fuel, in a realistic burner design,” says Andrea Gruber.

Scientific publications

- Chemical kinetics of hydrogen/ammonia flames:

- Spatial patter of NOx formation in hydrogen/ammonia flames:

- Blow-out limits of hydrogen/ammonia vs methane turbulent flames:

- Pressure scaling of flame propagation in hydrogen-enriched flames:

- Experimental demonstration of rich-lean staging of hydrogen/ammonia combustion in a gas turbine burner:

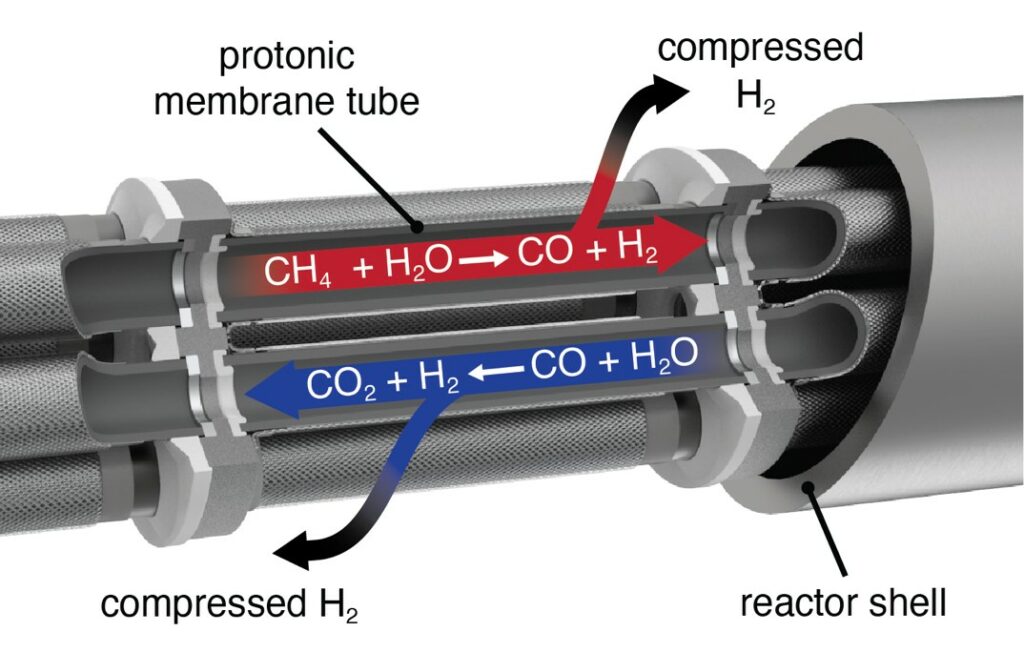

Science publication; Electrochemical production of hydrogen from natural gas

Proton-conducting membranes enables use of electricity as process energy to produce hydrogen from natural gas with low energy loss and simplified CO2 capture.

Hydrogen from natural gas

The journal Science has published “Single-step hydrogen production from NH3 , CH4 , and biogas in stacked proton ceramic reactors” authored by researchers from CoorsTek Membrane Sciences, University of Oslo, SINTEF and the research institute ITQ in Spain. CLIMIT-Demo has supported this research.

Traditional production of hydrogen from natural gas with CO2 capture takes place in several production stages with reforming, separation and compaction. Proton-conducting membranes gather these stages in one step with lower energy loss. This technology is also more suited for CO2 capture in connection with small-scale hydrogen production.

Like other electrochemical energy technologies such as batteries and fuel cells, the proton conducting reactors are made up of many small cells or membrane tubes. The new article shows how high energy efficiency from testing of single cells is maintained when cells are assembled in scalable units.

Two projects; Protonic

The development work in connection with the article is supported by CLIMIT-Demo through the project 618191 «Protonic». CLIMIT-Demo has also supported the next phase of the development work for project 620208 «Protonic Phase II».