CLIMIT; Researching CO₂ Capture with Microalgae

In response to climate change and the growing need for sustainable solutions, a new Norwegian project aims to develop innovative technology for CO2 capture using microalgae.

The Microalgae project is supported by CLIMIT with NOK 286,000, and led by Fredrik Mood from the company Mood Harvest.

The project involves a team of researchers and engineers working to develop and validate a photobioreactor specifically designed for the Nordic climate. This technology is intended to optimize the cultivation of microalgae, while contributing to the reduction of greenhouse gases in the atmosphere and producing climate-friendly raw materials and products.

Background and Objectives

The project’s primary goal is twofold. Firstly, the project team aims to clarify the potential of the business concept behind the photobioreactor. This will provide a solid foundation for making strategic decisions that can promote further development of the technology. Secondly, the project seeks to validate CO2 storage potential of microalgae, which could have significant implications for future climate efforts. The work is conducted in close collaboration with academic institutions to ensure that the technology is both scientifically grounded, and practically applicable in an industrial context.

– The photobioreactor is central to the project and is currently under patenting. The reactor is specifically adapted to the challenging light and temperature conditions characteristic of the Nordic climate, with significant variations throughout the year. By utilizing locally captured CO2 and artificial light to facilitate photosynthesis, the reactor enables industrial-scale cultivation of large quantities of microalgae, says Fredrik Mood.

Microalgae can either be used directly in various products or processed into raw materials, for the production of climate-positive or climate-neutral products. By integrating microalgae into production processes, the project can directly contribute to reducing the amount of CO2 in the atmosphere.

Technological Innovation and Circular Economy

The business concept behind the photobioreactor is rooted in the principles of the circular economy. This involves maximizing resource utilization and minimizing waste. The project envisions several potential revenue streams, including income from the reception and utilization of CO2, as well as the sale of raw materials and climate-neutral products. These products could range from biofuels and building materials to dietary supplements, cosmetics, and animal feed. By using CO2 as a resource rather than treating it as waste, the project helps to develop a more sustainable economy.

The photobioreactor under development stands out from existing technologies in several ways. It is designed to be industrially scalable, and requires less space than current solutions for microalgae cultivation, making it possible to grow microalgae on a large scale – even under challenging climatic conditions. The reactor is equipped with an innovative system for light and nutrient supply, along with other features which contribute to the optimal cultivation of microalgae.

One of the unique characteristics of the photobioreactor is its ability to continuously harvest microalgae. This reduces the need to shut down the reactor during harvesting, making production more efficient and potentially lowering the cost per kilogram of microalgae produced. The technology provides better control over environmental conditions inside the reactor, which is crucial for ensuring stable growth and high productivity. By integrating this technology into industry, a solution can be achieved that both reduces the carbon footprint, and increases the availability of climate-friendly raw materials.

Target Audience and Market Demand

The technology primarily targets small and medium-sized enterprises (SMEs) that are focused on reducing their carbon footprint and actively participating in the green transition. These businesses may have varying needs related to CO2 management. Some may seek to reduce their CO2 emissions through carbon capture, while others may see value in purchasing climate-neutral raw materials or products. For these companies, the photobioreactor could offer a solution that both reduces their carbon footprint, and enhances their competitiveness by ensuring access to locally sourced, climate-neutral raw materials.

The demand for climate-neutral raw materials is increasing, driven by stricter regulatory requirements and growing consumer demand for sustainability. The project highlights that access to locally produced climate-neutral raw materials will become an increasingly important factor in the coming years. The photobioreactor technology could play a central role in meeting this demand, by offering a scalable and sustainable solution for the production of such raw materials.

Challenges and Future Opportunities

– Although the project has significant ambitions, it also faces considerable challenges. Costs associated with the production and processing of microalgae have so far been a major barrier to commercial exploitation. To succeed, the project team must find ways to reduce these costs. The risk of contamination and challenges related to scaling up are also factors that need to be addressed to ensure success, says senior advisor Ernst Petter Axelsen of Gassnova.

The project team is aware of the importance of collaborating with other stakeholders, both in industry and academia, to overcome these challenges. A key part of the project’s future plan is to build a small-scale lab pilot in collaboration with research institutes such as NIBIO and SINTEF. This will provide opportunity to test and validate the photobioreactor technology under controlled conditions, and collect data as a basis for further scaling and commercialization. Accurate data collection through the pilot project is essential to validate estimates and improve the technology.

In addition, the project team sees many opportunities for future growth. Increasing demand for sustainable products, combined with technological advancements in biotechnology, provides grounds for optimism. Political support in the form of subsidies and regulations that promote renewable energy and carbon reduction, may also help create favourable market conditions for microalgae-based solutions. The project is also considering the possibility of using microalgae as an additive in concrete, which could reduce the need for cement and thus lower CO2 emissions from the construction sector.

The Way Forward

The project has already made significant progress, and initial studies confirm that microalgae cultivation can be an effective method for CO2 utilization and storage. However, further testing and development are necessary to fully achieve the original goals.

In the upcoming phase of the project, the aim is to demonstrate how the photobioreactor functions, with the goal of gathering better data and establishing a solid decision-making basis. This includes building a small-scale pilot/lab pilot and conducting experiments in collaboration with research institutions to validate the technology, in conjunction with various microalgae strains.

In parallel, the project will also explore opportunities to develop profitable carbon capture facilities tailored to small and medium-sized businesses in Norway. This includes feasibility studies for CO2 logistics for inland industries, which could form the basis for further development of full-scale demonstrators. In the long term, the goal is to build a full-scale demonstrator in collaboration with industrial stakeholders, which could contribute to realizing the technology on a large scale.

The project also plans to expand collaboration with academia and industry to develop new sustainable products from microalgae, with a particular focus on long-term CO2 storage and carbon reuse. With ambitious plans, the project points to a future where microalgae could play a key role in reducing greenhouse gas emissions, and contributing to a more sustainable economy.

CLIMIT; Kvitebjørn Varme Takes Carbon Action in an Arctic Environment

In Tromsø, the district heating system is operated by Kvitebjørn Varme AS. The company, in collaboration with Rambøll DK and Norsk Energi, is currently developing a supplier-neutral base concept for CCS at its facility.

The goal of avoiding commitment to a specific technology or supplier for capturing and storing CO2, is to reduce commercial risk by allowing multiple suppliers to compete, as the project approaches the investment decision stage. This strategy keeps the options open for the best available solution when the time comes for implementation. It also grants the organization control over the concept’s development and contributes to internal capacity building, which is crucial both during project maturation, and when the plant is handed over to operations personnel.

The Tromsø project is supported by CLIMIT with a grant of NOK 3.5 million. Charlotte Tiller is project manager.

Why Carbon Capture?

Carbon capture technology is particularly important for facilities that incinerate waste, where large amounts of CO2 would otherwise be released into the atmosphere. Kvitebjørn Varme burns 60,000 tonnes of residual waste annually, a figure that will soon increase to 110,000 tonnes when a new incineration line is completed in 2025.

Since 2022, Kvitebjørn Varme has been working on a plan to capture CO2 from flue gases generated during waste incineration. Project Ashlad aims to have a fully operational carbon capture facility by 2030.

How Did It All Begin?

– The project had already completed an idea study when I took over as project manager in 2023, says Charlotte. – I started by building an understanding of how carbon capture works and read a report from TCM, about various chemicals commonly found in flue gases that can damage the carbon capture process. I recognized many of these substances from my time working with emissions monitoring at Kvitebjørn Varme. We know that the presence of most substances which could harm carbon capture is generally low, but during operational disturbances or faults in the cleaning system, their levels can occasionally exceed what a carbon capture plant can tolerate, she continues.

Unlike most industries implementing carbon capture, flue gas from waste incineration is inherently more heterogeneous due to the varied nature of the fuel. Operational experience with carbon capture in the waste incineration sector is still limited. – There is only one waste incineration plant that has operated a carbon capture facility for several years. The heterogeneity also applies to CO2 concentration, temperature, and flue gas volume, which are critical for design. I became curious about how to design a carbon capture facility considering these variations, but found little knowledge on this in literature searches, says the project manager.

A good environmental initiative locally

– It is important for us that Ashlad not only becomes a positive climate measure globally, but also a good environmental initiative locally. I read up early on how carbon capture can affect the local environment and became aware that factors like solar radiation, local hydrology, and bioactivity can influence the surroundings’ response. Since the Arctic is typically characterized by significant seasonal variation in these factors, we decided to conduct an assessment earlier than usual in such project processes. This gives us ample time to implement the right measures for our surroundings. The facility will be designed with the environment as a guiding principle from the outset.

In Tromsø, no steam is produced from the plant, complicating energy integration at KVAS compared to the norm. However, there is year-round access to cold seawater, allowing for a more efficient cooling solution for the CO2 capture facility. Access to the sea also enables the establishment of a dedicated quay for CO2 export, which could be a significant advantage for the efficient transport of CO2 to permanent storage locations.

Internal Support

To tackle the challenges, Kvitebjørn Varme has also collaborated with other incineration plants in Norway, and engaged in dialogue with similar facilities abroad. – We are in discussions with technology suppliers to understand how they approach the issues in the project. Many assume standard methods will work, but we want to delve deeper to ensure we have all the necessary information before making significant investments, says Charlotte.

Unknown Variables

Charlotte highlights many aspects of carbon capture at waste incineration facilities that lack clear guidelines, especially regarding emissions regulations and flue gas quality over time.

– We have had to investigate whether it is sufficient to rely on average values over time, or if we need more detailed measurements to ensure that the capture process operates optimally. This has proven challenging, as it is difficult to find satisfactory answers both nationally and internationally, and it will likely be somewhat plant specific. To address the uncertainty, we must remain mindful of this as we further develop the project. This will be a central part of the strategy going forward.

International Collaboration

To tackle the challenges, Kvitebjørn Varme has also collaborated with other incineration plants in Norway, and engaged in dialogue with similar facilities abroad. – We are in discussions with technology suppliers to understand how they approach the issues in the project. Many assume standard methods will work, but we want to delve deeper to ensure we have all the necessary information before making significant investments, says Charlotte.

The Road Ahead

The project is currently in the pre-feasibility phase, which began in February this year with the allocation of CLIMIT support. In Q1 2025, the project will transition to the feasibility phase, where the goal is to select a technology. This will be followed by the planning phase, which aims to establish a comprehensive basis for an investment decision in 2027. – Our goal is to have carbon capture in operation by 2030. It is an ambitious timeline, but we are working diligently, says Charlotte.

Kvitebjørn Varme is considering collaboration with other projects, and is exploring transport solutions for delivering CO2 to various storage locations, both individual and collective.

– Locally, we aim to reduce emissions and establish a more sustainable energy solution for Tromsø, while creating new jobs in the process. So far, we have benefited greatly from sparring with others in the industry, and hope that our openness about our experiences from the feasibility study can contribute back, allowing us to continue to mature together. The project is considering the possibility of applying for additional funding to continue knowledge development, says project manager Charlotte Tiller.

Senior Advisor Ernst Petter Axelsen at Gassnova is CLIMIT’s responsible for the Kvitebjørn Varme project, and also serves as their advisor. – Establishing a carbon capture facility of this scale, with a new and exciting technological angle, is a significant investment for the company. Many factors come into play when assessing costs. Therefore, having sufficient resources and the right expertise to manage all aspects of development is crucial. Moreover, knowledge exchange with the industry is vital, and something Kvitebjørn Varme emphasizes. As a regulatory actor, this is something we particularly note, says Axelsen at Gassnova.

CleanExport: Norway’s Role in a Decarbonized European Energy System

Europe’s need for clean energy is growing, and today Norway is well-positioned as a supplier. The SINTEF-led CleanExport project explored how Norway should further position itself as a central player in the export of clean energy to Europe.

Conducted by SINTEF from 2020-2024, the project received 14.7 million NOK in funding from the Research Council of Norway.

CleanExport. Illustration: SINTEF

Background

was developed in the wake of the Paris Agreement and the increasing need for decarbonization of the European energy system. The project examined how Norwegian clean energy exports would evolve in response to reduced demand for fossil fuels in Europe. The main goal was to provide strategic guidance and investment support to strengthen Norway’s position as a future supplier in this area.

During the course of the project, two unforeseen events occurred: the COVID-19 pandemic and the Russian invasion of Ukraine. Both significantly altered the European energy system, leading to large fluctuations in energy demand, supply, and prices. Additionally, new legislation was introduced in the EU through revisions of the Renewable Energy Directive, the European Green Deal, and REPowerEU.

Significant Impact

The project’s focus on optimization models for energy systems provides both industry and research partners with an overview of existing models and their benefits, a new version of a sector-coupled European electricity model (EMPIRE), and a new flexible energy system modelling framework (EMX). This framework can be adapted to specific needs in individual analyses and is openly available on GitHub.

Advantage of EMX lies in giving users a high degree of flexibility in designing a specific model instance. Examples include which cost descriptions are used for a technology in each region, how efficiency is modelled, or which technologies are available in the individual regions.

– Studies in the project provided both industry partners and policymakers with knowledge on how Norway can remain an energy export nation in the future. It is crucial to understand how Norwegian energy export infrastructure is affected by external circumstances. This provides new insights into the various energy export options, says Aage Stangeland from CLIMIT R&D/the Research Council of Norway.

New Insights

A key focus of the project was developing an optimization framework for energy system models. Future energy system scenarios were simulated, providing the following insights:

- Norway can maintain and further develop its role as an energy export nation in a decarbonized European energy system.

- Investments in renewable power production are crucial for the future export of clean energy, regardless of whether the energy is exported as hydrogen, ammonia, or electricity.

- Prospects for future Norwegian hydrogen exports indicate hydrogen production from natural gas reforming with CCS in the initial phase. With the potential for hydrogen from electrolysis later. The initial dominance of natural gas is due to the lack of available power in the coming years.

- Development of EnergyModelsX (EMX) – a modular, multi-energy modelling framework. Significant improvements to the existing power system model EMPIRE.

The CleanExport project also had secondary goals:

- Integration and harmonization of tools for energy system expansion planning to enable technical-economic quantitative analysis.

- Study of complementarity and synergies between renewable sources, natural gas, hydrogen, ammonia, and CCS within an energy system context.

- Establishment of high-quality data and defining the most relevant case studies.

- Study of how large-scale Norwegian hydrogen production for energy export can trigger a domestic hydrogen market.

- Education of a PhD student and a postdoctoral fellow on topics related to mathematical optimization models for integrated natural gas and power markets, and operational flexibility for low-carbon energy systems.

Dissemination

The CleanExport project has resulted in several published articles and drafts for new ones. During the project period, results were presented to industry partners at semi-annual seminars. Additionally, CleanExport results were presented at several conferences and used as a basis for op-eds.

– An important legacy of the CleanExport project is related to the EMX modelling framework and modifications to the EMPIRE model. EMX was presented through JuliaCon 2023 and two open webinars. This is applied in several subsequent EU projects, NFR projects, and FME InterPlay. Furthermore, SINTEF is in contact with several industry partners to facilitate the integration of EMX in their organizations, says project leader Julian Straus at SINTEF.

CleanExport organized a seminar titled “Clean Energy Export from Norway” in Oslo, attended by 35 participants from research, industry, and NGOs. The seminar conveyed knowledge from the project far beyond the project group and participating partners. Results from the CleanExport project are also combined with results from several other FME projects, all led by SINTEF.

CO₂LOS IV: Optimization of CO₂ Transport

CO2LOS IV aims to optimize the logistics of maritime CO2 transport and reduce costs. Major partners such as Equinor, TotalEnergies, and Gassco have been involved from the start, demonstrating significant interest in the project.

CO2LOS IV is a collaboration between the main partners Brevik Engineering AS and SINTEF AS, with a budget of 10.5 million NOK. CLIMIT contributes 37 percent of the funding. Brevik Engineering serves as the project owner and manager, working closely with SINTEF and other partners to execute the project.

Copyright: Brevik Engineering

Building on Previous Phases

The project builds on experiences and results from previous phases, CO2LOS II and III. These phases focused on developing various tools to reduce CO2 transport costs and exploring aspects such as liquefaction, interim storage, and terminals. CO2LOS IV utilizes this knowledge to test realistic scenarios in both Europe and Asia. The project examines CO2 transport between ports, and from inland areas to ports and then to storage sites.

– The CO2LOS projects began in 2018 as a collaboration between Brevik Engineering and SINTEF, with funding from CLIMIT. We enlisted major partners such as Equinor, TotalEnergies and Gassco. As the project progressed, interest grew, and significant players like Mitsubishi Heavy Industry, Mitsubishi Cooperation, BP, Mitsui OSK, IMODCO/ SBM and Exxon Mobil joined, says Ragnhild Skagestad of SINTEF AS, project manager for the CO2LOS projects.

CO2LOS Cost Tool

The “CO2LOSs Cost Tool” was developed to estimate costs across the entire logistics chain. Different scenarios can be run to see how changes in volume, pressure, or transport methods affect costs for each segment, whether by pipeline or ship. The tool was developed in collaboration with project partners and is owned by Brevik Engineering and SINTEF AS.

Environmental Impact and Public Acceptance

– We analyse emissions in each part of the transport chain and estimate the impact of our changes, such as on the ship’s propulsion system. We prioritize environmentally friendly solutions. Additionally, public acceptance is a challenge. Good communication and understanding from authorities and local communities are crucial, especially in projects involving transport through sensitive areas. Being open and transparent about plans and results is part of the solution, adds Ragnhild in SINTEF.

Technical Challenges

The core challenges of CO2LOS IV include optimizing the entire logistics chain for CO2 transport. This encompasses everything from liquefaction and compression to interim storage and terminals. The project has explored the possibility of directly injecting CO2 into offshore reservoirs, which, although challenging, could significantly reduce costs.

– Ship transport of CO2 is a very flexible solution, particularly considering advances in autonomy and low-emission ships. We believe this will be a vital part of future CO2 management solutions. Ship transport can be cost-effective and adaptable to various geographic and logistical needs, making this solution highly attractive, concludes Ragnhild Skagestad of SINTEF AS.

Key to Success

Ernst Petter Axelsen from Gassnova is CLIMIT’s representative in CO2LOS IV. He believes the strong collaboration between the different partners is the foundation for the project’s dynamic success. – This has enabled the project to share knowledge and experiences efficiently. It has also been crucial to balance research and practical engineering work, facilitating realistic and applicable solutions. This aligns with CLIMIT’s objectives and is a key criterion for our funding decisions, says Ernst Petter from Gassnova.

CO2LOS IV is scheduled for completion in mid-2025.

CO₂ Transport; Norwegian Expertise Sets Impurity Limits

KDC-IV Project: Advancing Experimental Data and Tools for CO2 Transport Systems.

The KDC-IV project continues previous initiatives aiming to create experimental data, knowledge, and tools to establish impurity limits in CO2 transport systems. Led by the Institute for Energy Technology (IFE) in Kjeller, the project seeks to enhance safety and reduce costs in CO2 transport. It is supported by CLIMIT with approximately NOK 5.6 million. Industrial partners include Shell, TotalEnergies, Equinor, Gassco, Vallourec, BP, Chevron, ExxonMobil, ArcelorMittal, Air Products, ENI, Saudi Aramco, Wintershall Dea, EBN, Fluxys and Gasunie.

Water Induces Corrosion

Material selection is crucial in the overall cost of CO2 transport systems for carbon capture and storage. Cost considerations make carbon steel the preferred material for long pipelines and ship transport. However, carbon steel corrodes in the presence of water or water-bearing phases, which can form due to impurity reactions. Therefore, controlling CO2 composition and system operation is essential to prevent the formation of water-bearing phases.

Currently, various specifications and recommendations exist for the types and concentrations of impurities allowed in the CO2 stream. Traditionally, these limits have been set from health, environmental, and safety perspectives, rather than based on material integrity, due to a lack of knowledge. This knowledge gap has made it challenging to define specifications that ensure safe operation and long-term material integrity.

Expertise at Kjeller

The IFE at Kjeller, near Oslo, leads this CLIMIT-funded project. – Initially focused on nuclear power research, IFE expanded its activities in the early 1980s to include other fields due to the limited role of nuclear power in Norway. Early research emphasized oil and gas, later extending to wind, solar, hydrogen, battery technology – and CO2 capture and storage, says Gaute Svenningsen – project manager at IFE.

Activities in KDC-IV

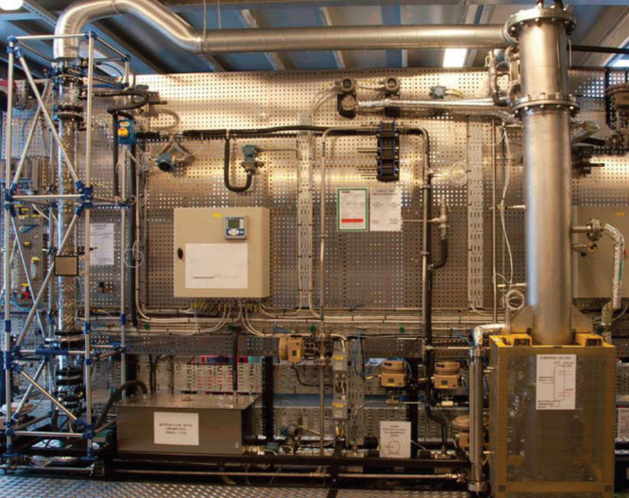

The project involves extensive experiments with CO2 impurities, both with and without corrosion testing. Many experiments cover conditions and impurities not previously tested, including those for ship transport (low temperature and moderate pressure) and pipeline transport of liquid CO2 (ambient temperature and high pressure). Under these conditions, CO2 will be either liquid or supercritical.

Previous KDC project results have been used to enhance OLI Systems’ thermodynamic model, enabling it to simulate reactions in liquid and supercritical CO2. KDC-IV results will be compared with OLI calculations to assess the model’s accuracy. This knowledge is invaluable for operators using these tools in real projects, whether in design basis development or full-scale project operation.

– We must constantly find new methods to manage impurities. Capturing CO2 from different sources introduces various components that must be considered. Balancing the extent of purification against permissible impurity levels is crucial. Unfavourable combinations of impurities may create undesirable reaction products in the facility, such as acid precipitates, particles, or elemental sulphur, which can be corrosive and cause significant damage, Gaute explains.

Research Findings

At IFE, four researchers focus on KDC-IV, while two others work on well and reservoir-related CO2 injection issues. IFE manages numerous simultaneous projects and receives substantial external interest in its CO2 transport data.

KDC-IV’s work has shown that many impurity combinations are mostly inert, while others lead to chemical reactions. Some combinations result in a separate water phase with high concentrations of sulfuric acid, nitric acid, and elemental sulphur, which is corrosive to carbon steel.

– We have excellent technicians and engineers at IFE, and a very competent workshop. We order most research equipment as components and assemble them ourselves. This approach is more efficient than ordering everything pre-assembled, Gaute adds.

Competent Environment

Ernst Petter Axelsen of Gassnova, CLIMIT’s representative for KDC-IV, notes that IFE is a world leader in this field, possibly the only entity capable of conducting such high-level experiments. The work is labour-intensive and requires expensive equipment and extensive laboratory experience. Therefore, expectations are high for IFE’s achievements leading up to the project’s conclusion in 2027, Ernst Petter says.

Future Work in KDC-IV

The KDC-IV project will study precipitation of separate acid phases in liquid CO2 with various impurity combinations. It will investigate the composition of acid phases and examine the behaviour of such droplets in CO2 pipelines, using a high-pressure flow loop. Experiments will also explore effects of different impurities in CO2 transported in the gas phase (low pressure).

The KDC-IV project aims to provide comprehensive knowledge on corrosion and chemical reactions in CO2, which is essential for setting specifications for the safe transport of CO2 in pipelines and on ships.

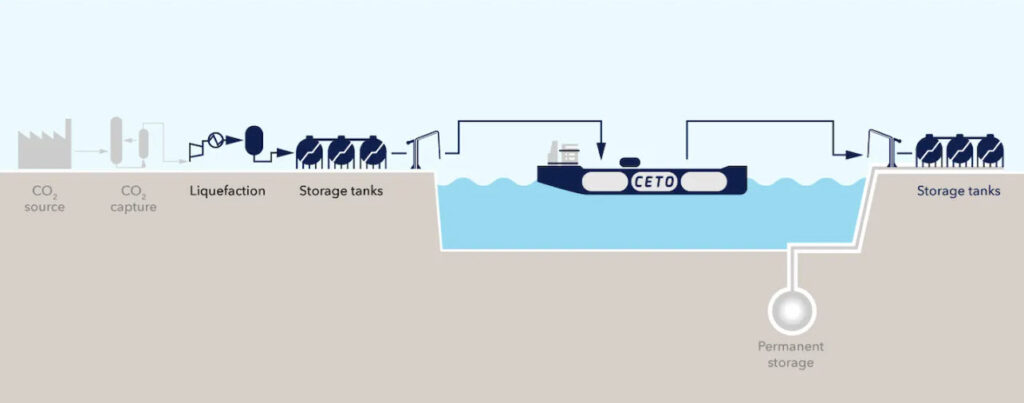

Low-Pressure CO₂; Greater Transport Volumes and Increased Capacity

To accommodate the foreseen increase demand for transportation of CO2 for CCS purposes, a development towards larger ships and transported volumes is expected.

A low-pressure transport system is an alternative to medium pressure and is the preferred solution for most of the projects accommodating cargo volumes larger than 20 000 m3.

Transport Conditions

At low-pressure conditions, the liquid CO2 is transported at pressure and temperature closer to the triple point compared to today’s industry practice. The reduced pressure and temperature allow for larger cargo tank diameter, and also benefits from increased liquid product mass density – leading to larger cargo capacity per ship, while reducing the overall shipping cost.

CETO Project Development

The project “CO2 Efficient Transport via Ocean” (CETO) managed by DNV is a partnership between Equinor Energy AS, Gassco, TotalEnergies, EP Norge AS, and Shell Global Solutions International B.V. CLIMIT supported the CETO project with over 8.2 million NOK, which is 32% of their total budget.

Transport; Project Purpose

– CO2 transport by ship has been performed for several decades – but on a limited scale for businesses in the food, cleaning, and chemical industries. Currently, there is no operational experience with low-pressure ship transport of CO2, which is therefore associated with a higher risk compared to the medium-pressure alternative. Such risks are minimized with proper design of the processes in the transport chain – says Ernst Petter Axelsen at Gassnova.

CETO investigates the fundamental aspects of a low-pressure value chain – and aims at reducing the uncertainties related to design, construction, and operation as well as enhancing solutions for ship transport of CO2.

Project Phases

The project was divided into a Planning Phase and an Execution Phase.

The goal of the Planning Phase (Q2 to Q4 2020) was to identify novel elements, associated technical uncertainties and to establish relevant qualification activities, necessary to address these risks and the uncertainties.

The qualification activities were carried out in the Execution Phase (Q3 2021 to Q1 2024) and encompassed:

- Conceptual design of an onshore conditioning and liquefaction plant, and experimental demonstration of liquefaction at low pressure (in synergy with SINTEF industry)

- Development of a suitable conceptual ship design and cargo handling system for transporting 30,000 m³ CO2

- Design of the cargo containment system and qualification of a selected material to accommodate the large cargo weight, ensure constructability and operation at design temperature

- Design, construction and commissioning of a test rig resembling a ship-to-terminal cargo handling system – to investigate, via experimental activities, the operability of a low-pressure system, and determine a safe envelope for the operations

- Benchmarking and validation of simulation tools for assessing cargo handling operations in the low-pressure domain.

- Experimental and modelling activities within CO2 thermodynamics to reduce uncertainty in digital design tools.

Project Results So Far

– The results of the Qualification Activities indicate no technical obstacles to the deployment of low-pressure CO2 ship transport value chain. Though there are technical elements that require further attention during project specific development. More specifically, CETO has demonstrated the feasibility of a low-pressure liquefaction plant by developing a conceptual design that meets the design specifications. The conceptual design of the ship, cargo tank, and cargo handling system shows that a dedicated 30K low-pressure LCO2 carrier can be developed, in compliance with the current rules and regulations – says Gabriele Notaro, project manager at DNV.

The testing campaign on the medium-scale pilot rig demonstrated that the cargo handling operations could be carried out without dry ice formation, at vapor pressure in the range of 6 to 9 barg. Lastly, the accuracy and suitability of design process simulation tools were benchmarked with good agreement against experimental tests. These activities provided valuable experience and understanding of the fundamentals of a low-pressure value chain,

and the results indicate that low-pressure is technically feasible.

CLIMIT’s Contribution

– CLIMIT has been an essential facilitator, providing valuable guidance on handling the project through different phases. Despite technical challenges and elements requiring continuous industry focus, the project partners will use the results and knowledge in internal decision-making processes and specific CCS infrastructure activities – concludes Gabriele Notaro at DNV.

Future Plans

CETO partners are discussing further activities related to operations under low-pressure conditions, including:

- Investigate alternative materials suitable for use at low temperatures, addressing production and welding technology and to identify a cost-effective solution for the relevant temperature ranges

- Evaluation of the feasibility, benefits, and technical barriers of using re-liquefaction on low-pressure CO2 ships to control boil-off during transport, thus reducing the necessary design pressure margins for cargo tanks

- Investigation of solutions for different impurities, including acid produced by chemical reactions under low-pressure conditions

- Examination of chemical reactions between impurities under low-pressure conditions and possible corrosion effect

- Determination of a representative CO2 product specification for the low-pressure option, which may involve analysing the balance between lowering impurity levels and reducing corrosivity.

Publications Following the CETO Project

To date, the following publications have been released based on the project’s work:

- Gabriele Notaro, Jed Belgaroui, Knut Maråk, Roe Tverrå, Steve Burthom, Erik Mathias Sørhaug “CETO: Technology Qualification of Low-Pressure CO2 Ship Transport” 16th Greenhouse Gas Control Technologies Conference, Lyon 23-27 October 2022

- Michael Drescher, Adil Fahmi, Didier Jamois, Christophe Proust, Esteban Marques-Riquelme, Jed Belgaroui, Leyla Teberikler, Alexandre Laruelle. “Blowdown of CO2 vessels at low and medium pressure conditions: Experiments and simulations” 0957-5820/© 2023 Institution of Chemical Engineers. Published by Elsevier Ltd.

- GHGT16 Proceedings, Poster presentation, “BLOWDOWN OF CO2 VESSELS AT LOW AND MEDIUM PRESSURE CONDITIONS: EXPERIMENTS AND SIMULATIONS”; Michael Drescher, Adil Fahmi, Didier Jamois, Christophe Proust, Esteban Marques-Riquelme, Jed Belgaroui, Leyla Teberikler, Alexandre Laruelle. 16th Greenhouse Gas Control Technologies Conference, Lyon 23-27 October 2022

- Rod Burgass, Antonin Chapoy “Dehydration requirements for CO2 and impure CO2 for ship transport,” Fluid Phase Equilibria. Volume 572, September 2023, 113830

- Antonin Chapoy, Pezhman Ahmadi, Rod Burgass “Direct Measurement of Hydrate Equilibrium Temperature in CO2 and CO2 Rich Fluids with Low Water Content,” Fluid Phase Equilibria Volume 581, June 2024, 114063

- Franklin Okoro, Antonin Chapoy, Pezhman Ahmadi, Rod Burgass “Effects of non-condensable CCUS impurities (CH4, O2, Ar and N2) on the saturation properties (bubble points) of CO2-rich binary systems at low temperatures (228.15–273.15 K)” Greenhouse Gases: Science & Technology, 26 December 2023

Compact CO₂ Capture: Absorption Without Large Space Requirements

Minox Technology AS has developed a compact amine-based CO2 absorber designed for applications where space is a critical concern.

This Minox-project has received support from the CLIMIT program, amounting to over 3.2 million NOK. The technology has been tested at the University of South-Eastern Norway (USN) in their CO2 capture rig.

– The goal of Minox’s compact CO2 capture system is to reduce the carbon footprint of energy operators by enabling capture in locations where conventional technology is difficult to use due to space constraints – says Ole Morten Isdahl of Minox Technology AS.

CLIMIT Support Granted in October 2022, with Three Project Objectives

- Document the operation and performance of the Minox “CO2 Capture System” under various conditions

- Assess the technology’s potential for use in offshore oil and gas operations considering space and weight limitations

- Develop knowledge and expertise for scaling up the system and further large-scale testing

Activities and Implementation

The project involved a research and development effort, including engineering, construction, and testing at USN, alongside analyses conducted by Minox and its partners. The CLIMIT-supported project has resulted in two publications, presented at the Offshore Technology Conference in Brazil (October 2023) and the Offshore Technology Conference in Houston (May 2024). In Houston, Minox participated with a booth and presented the publication during the session “Innovative Topside Design.”

– We conveyed both the core technology and the opportunities for compact CO2 capture to energy companies during the conference. There is increasing interest in more compact and space-saving solutions – continues Ole Morten Isdahl.

Results

The compact solvent-based capture technology has undergone extensive testing in USN’s test rig. The goal was to quantify effects on process variables related to CO2 capture from flue gas streams, with both low and high CO2 concentrations. Minox`s technology is based on static mixers and separators for gas-liquid contact. Tests were conducted using the well-documented CO2 capture solvent (MEA).

– Four months of operation have shown promising CO2 capture rates for both low and high CO2 concentrations. testing also indicates an improvement in CO2 mass transfer, combined with reduced size requirements. The technology can be retrofitted to facilities with existing emission points and is particularly suited for offshore installations – concludes Ole Morten Isdahl.

Future plans for Minox

Moving forward, work will include scale testing and demonstration under real operating conditions at an emission source. Minox also aims to collaborate with more partners to realize pilot plants with complete integration of CO2 capture, energy optimization and other processing needs.

CCS and CO₂-EOR; Norway contributes to new standards

A CLIMIT-supported project will contribute to deliveries to ISO TC265. Purpose is to design international standards and technical reports for CCS and CO2-EOR.

By using internationally recognized standards, important barriers to the spread of CO2 management can be dismantled.

Standards create value

– International standards are crucial for advancing CCS, especially for CCS value chains across national borders. Norway has skilled experts in the field, and we are pleased that CLIMIT can contribute to supporting IOM Law in this important work – says Camilla Bergsli, senior advisor at Gassnova.

ISO TC265 was established in 2011, and today 28 countries participate in the negotiations. ISO TC265 has six working groups, each covering an element of the value chain – capture, transport, storage, cross-cutting issues, CO2 transport by ship, and CO2-EOR. “Carbon Dioxide Enhanced Oil Recovery” (CO2-EOR) is a method used to increase the amount of oil extracted from exploration fields, where the injected and utilized CO2 is stored in the reservoir. A separate committee under Standards Norway coordinates the participation of Norwegian experts in the various working groups – representing the span of Norwegian CCS and CCUS knowledge.

Standards and technical reports which are developed, create common understanding, gather and spread technical expertise, and provide a commercial basis for the technologies. Moreover, safe and effective implementation of CCS and CO2-EOR increases acceptance among decision-makers and in society at large.

Project Objectives

The purpose of this CLIMIT-supported project is to contribute to the finalization and publication of documents in ISO TC265, support Norwegian experts in promoting the country’s interests, and disseminate knowledge about the standards and the work. Norwegian matters and needs must be considered so that the documents are correctly applied in Norway, and do not conflict with Norwegian frameworks. ISO TC265 aims to contribute to predictability, cost reductions, and operational frameworks within the legal preconditions in a Norwegian, European, and international framework.

– Standardization is an important building block for the commercialization of CCS. We see that more companies are using the TC265 standards in their projects. Authorities from around the world have adopted these standards or are considering doing so, to bridge gaps or regulate technical details in their own CCS frameworks. In its Industrial Carbon Management-strategy from February this year, EU has communicated an increased focus on the use of standards for the European CCS framework.

This is to facilitate a commercial European market for CCS, and underscores that the work being done in the Norwegian mirror committee is more important than ever – says Ingvild Ombudstvedt, lawyer at IOM Law.

Ingvild Ombudstvedt ready to work for new standards.

Activities

The storage standard (27914) from 2017 has been reopened for revision, e.g. to include tools for quantification and verification of stored CO2 volumes. A lot of work was put into the first part of the project. An updated standard is aimed for 2025. Furthermore, the technical report for converting CO2-EOR to pure storage was almost completed in the fall of 2023. Publication is expected in 2024.

Fall 2023, the technical report for CO2 ship transport was also sent for review by the international committee. Publication is expected in 2024.

In 2023, there have been numerous activities related to the dissemination of project results, and assistance to new ISO TC265 countries. Presentations have been conducted at TCCS in Trondheim and at the 100-year anniversary of Standards Norway in Oslo. Additionally, in workshops for Asian developing countries organized by the U.S. Department of Commerce, experts from Norway, USA, Canada, Japan, and Australia have shared views and experiences from the standardization work.

Highlights

The project has contributed to completion of technical reports concerning the conversion of CO2-EOR to pure storage, and concerning CO2-transport by ship. The U.S. Department of Commerce – Commercial Law Development Program (CLDP), has recognized the value of ISO TC265 for regulatory development of CCUS in developing countries.

In the latter part of 2023, a technical committee for CCUS was established in the European Committee for Standardization. This committee will focus on converting more of the standards under TC265, into European matters – as well as negotiating new standards in which the ISO standards do not consider. Norwegian representatives participate in this work going forward.

Suggests a CO₂ “National Transport Plan”

In the phase between CO2 capture and storage, there will be a need for an infrastructure network, where CO2 transport is planned and coordinated at a national level. CLIMIT has granted NOK 200,000 for a concept study under the direction of SINTEF Industry and SINTEF Energy, which will further explore the future transport routes for CO2.

Ragnhild Skagestad from SINTEF Industry leads the study, which could result in a contribution to a possible “National Transport Plan” for CO2 – similar to the current Norwegian National Transport Plan (NTP), a document which outlines Norway’s transport policy and investments for a twelve-year period.

Study Phase

– At SINTEF we are now focusing on developing a roadmap for CO2 management, which includes the transportation of CO2 between and within clusters that are already involved in the handling of CO2. The project is in a study phase, with the potential to become a full-scale national initiative. The goal is to develop a holistic approach which integrates the various industry segments for better collaboration and efficiency – says Ragnhild.

One of the biggest challenges is coordinating the transportation of CO2, from various capture sites to storage sites. The project is considering different transport methods – such as pipelines, ships, trains, and trucks – each with their unique challenges and requirements. It’s crucial to create infrastructure which also covers future needs, so that pipes and storage may accommodate increasing CO2-volumes.

Standardization

Ragnhild and her colleagues at SINTEF are evaluating how standardized CO2 transport methods can be effectively utilized, to handle different geographical and industrial conditions while exploiting site-specific advantages. – For instance, pipelines may be ideal in some regions, and shipping might be better suited in other parts of the country. Transnational CO2 transport may lead to other transport needs – Ragnhild notes.

An agreement was recently signed between several countries, including Norway, making transnational CO2 transport legal.

Norway has a unique position thanks to its advanced technological knowledge and experience from the offshore sector. This project has the potential to set standards that could also be implemented across Europe. SINTEF is in dialogue with the EU to develop a joint strategy which also considers country specific conditions and needs.

Collaboration is Key

– We interact closely with industrial clusters to ensure that the solutions we develop are scalable and adaptable. This involves exchanging knowledge and technologies that can promote the standardization of the infrastructure. Coordinating the CO2 networks is absolutely essential to achieve an effective national strategy – Ragnhild adds.

Through the project, SINTEF will engage in dialogue and collaboration with ongoing clusters in various locations across Norway. This includes all, from large industrial conglomerates to innovative startups. During the concept study, a workshop will be held where potential partners are invited. The collaboration also extends to academic institutions to ensure the project stays up to date with the latest research.

What Happens Next?

Ragnhild is optimistic and looks forward to moving from ideas to a feasibility study, where a roadmap for CO2 infrastructure will be developed. This includes detailed mapping of CO2 sources and potential storage sites, along with the development of efficient and sustainable infrastructure. The goal is to create a robust system for future CO2 infrastructure, not only serving Norway but also addresses global challenges.

– This CO2 infrastructure project has the potential to strengthen Norway’s position as a leader in CO2 management. By developing technologies and then sharing them, SINTEF’s work can contribute to European collaboration against the climate change. This combines industrial development and sustainability – says Ernst Petter Axelsen, senior advisor at Gassnova and CLIMIT.

Capturing Low CO₂ Concentration

A CLIMIT-supported research project has made progress in capture technology for industrial emission sources with low CO2 concentration.

Liquid absorbent solutions, such as amines, can be used to capture CO2 in flue gases from various types of processes. The project addressed the challenges of absorption-based CO2 capture processes, which have proven to be less effective when dealing with diluted gas streams. Emission sources with low CO2 concentration can vary widely depending on industry, technology, and emission reduction measures.

Different Emission Sources

An example of low-CO2 emission sources is flue gases from the combustion of natural gas, which generally have a lower concentration compared to coal or heavy oil. – The purpose of this project was to explore and improve the efficiency of carbon capture related to flue gases with lower CO2 concentrations, and to investigate whether degradation products in the absorbent affected the capture capacity – says Svein Bekken, senior advisor at Gassnova.

Extensive Pilot and Laboratory Tests

The research team conducted a series of pilot and laboratory tests. A mobile testing unit (MTU) was used to investigate carbon capture processes at CO2 concentrations of 2.5 to 5%. Tests showed that even with low CO2 concentrations, it was possible to achieve capture efficiency between 85 and 95 percent. The results also indicated a significant increase in energy consumption for carbon capture at lower CO2 concentrations, which was expected from theoretical calculations.

Laboratory tests were also conducted to study the effect of degradation products on the solution’s absorption properties. The tests indicated that degradation products examined did not significantly affect the solution’s ability to absorb CO2.

Important for Further Development

This project has achieved its main objectives by demonstrating the feasibility of effective CO2 capture at lower concentrations, without simultaneously proving fundamental obstacles to the use of technology. Research also shows that some degradation products could be partially regenerated, opening up savings in solvent consumption.

– These findings represent important steps forward for plants operating with lower CO2 concentrations in the flue gases. The insights will be further utilized in the implementation of more efficient carbon capture solutions for a range of industrial applications – Svein Bekken states.

Project partner: University of South-East Norway

Project leader: Aker Carbon Capture