CCS Excellence; The 2025 CLIMIT Award Winners

A key highlight of CLIMIT Summit 2025 was the CLIMIT Award, which recognizes individuals who have demonstrated extraordinary dedication and contributions to advancing CCS technologies.

At the 2023 CLIMIT Summit, the CLIMIT Award was presented for the first time. This year, the award celebrates three winners who have been instrumental in the launch of Longship, each making invaluable contributions to Norway’s ambition of establishing a full-scale CCS value chain. These pioneers – Oscar Graff, Per Brevik, and Philip Ringrose – exemplify innovation, perseverance, and leadership in the field.

Oscar Graff: A Trailblazer in CO2 Capture

For nearly three decades, Oscar Graff has been at the forefront of CO2 capture technology, playing a critical role in its development from laboratory research to full-scale industrial applications. His journey in CCS began in 1997, a time when carbon capture was still in its infancy and faced significant scepticism. However, Graff’s unwavering determination and visionary leadership have propelled the field forward, overcoming obstacles and transforming challenges into opportunities.

A defining aspect of Graff’s career has been his ability to bridge the gap between research and industrial deployment. Under his leadership, CO2 capture technology advanced through a step-by-step process: from early-stage laboratory testing to pilot demonstrations at Tiller, and ultimately, large-scale implementation at the Technology Centre Mongstad (TCM) – world’s most advanced CO2 capture testing facility. His dedication ensured that the technology not only met scientific validation but also gained commercial viability.

One of Graff’s remarkable achievements was leading the development of a mobile CO2 capture unit, housed in a container, which travelled the world to demonstrate the feasibility of CCS in diverse industrial settings. This pioneering approach significantly contributed to the global recognition of Norwegian CO2 capture expertise. As a senior leader at Aker, later integrated into SLB Capturi, Graff played a crucial role in ensuring CO2 capture technology transitioned, from experimental projects to market-ready solutions. His relentless advocacy and technical expertise have made a lasting impact, paving the way for CCS adoption worldwide.

Per Brevik: A CCS Driving Force in the Cement Industry

A true champion of large-scale CCS implementation, Per Brevik has been instrumental in bringing CO2 capture to one of the most challenging sectors: cement production. His vision and persistence have played a decisive role in the realization of Norway’s first full-scale industrial CCS project, at Heidelberg Materials’ Brevik cement plant.

Brevik’s influence within the CLIMIT program dates back to 2012, when he was a key figure in securing the largest single funding allocation ever granted by the program’s steering committee. Recognizing the strategic importance of CCS in the cement industry, he worked tirelessly to turn the vision of carbon capture at Brevik into reality. His ability to rally industry stakeholders, secure financial backing, and navigate regulatory complexities was essential to the project’s success.

As Director of Sustainability at Heidelberg Materials, Brevik faced the challenge of convincing an international corporation – initially hesitant about CCS – to embrace the technology as a key climate solution. Through relentless advocacy and strategic leadership, he succeeded in positioning CCS as an integral part of the company’s sustainability roadmap. His efforts have set a global precedent, demonstrating that large-scale CO2 capture in cement production is not only feasible, but also commercially viable.

The cement plant in Brevik is now a cornerstone of the Longship project, marking a historic milestone in Norway’s CCS journey. By proving that carbon capture can be integrated into hard-to-abate industries, Brevik has laid the foundation for future projects worldwide.

Philip Ringrose: A Global Authority on CO2 Storage

In the field of CO2 storage, few individuals have had as profound an impact as Dr. Philip Ringrose. A leading geoscientist and internationally recognized expert in reservoir modelling, Ringrose has dedicated his career to ensuring the safe and effective long-term storage of captured CO2. His work has been instrumental in bridging scientific research and practical applications, providing the foundation for large-scale CCS deployment.

Throughout his career, Ringrose has contributed groundbreaking research on geological storage capacity, site selection, and monitoring techniques. His expertise has played a crucial role in shaping best practices for CO2 storage, ensuring captured emissions are safely and permanently sequestered underground. As a professor and industry advisor, he has mentored the next generation of CCS professionals, fostering a collaborative global network dedicated to advancing CO2 storage science.

Beyond his technical contributions, Ringrose is admired for his leadership, mentorship, and advocacy. His ability to communicate complex scientific concepts to diverse audiences – from policymakers to industry executives – has been invaluable in securing broad-based support for CCS initiatives. His contributions extend beyond Norway, influencing international CCS standards and collaborations. Ringrose’s work has not only advanced scientific understanding but has also played a crucial role in ensuring that CCS remains a key pillar in global climate strategies.

Congratulations to Oscar Graff, Per Brevik and Philip Ringrose!

NOK 10 million for Carbon Removal Projects

For the first time, the CLIMIT programme has earmarked funds for carbon removal projects (CDR).

To achieve climate neutrality, it is not enough to stop all emissions CO2 must also be removed from the atmosphere (carbon removal), according to the IPCC. The CLIMIT programme will now help to realise this through value creation in Norway. Do you have an idea for a project? Get in touch with us!

Growing demand for Carbon Dioxide Removal (CDR) by 2050

Interest in Carbon Dioxide Removal (CDR) is increasing, and CLIMIT has allocated funding for such projects in 2025. The CLIMIT programme will process applications on a rolling basis, and all applicants must follow CLIMIT’s standard procedure, which can be found here.

Examples of technological solutions within CDR:

- DACCS – Direct Air Capture (DAC) with Geological Storage

- BioCCS – capture and geological storage of CO2 from industries using biological feedstocks/fuels

- Biochar – for industrial and agricultural use with long-term soil storage (as a soil amendment).

- Mineralisation (formation of carbonates for durable storage)

BioCCS: The most mature solution

BioCCS is currently the most mature solution with the greatest potential in terms of tonnes of CO2 stored per year. The industry views bioCCS as an enabler for CCS, as capturing and storaging biogenic CO2 emissions can facilitate sale of carbon credits, strengthening business models.

In Norway, CDR activities primarily focus on bioCCS and biochar. Additionally, Norwegian companies like Removr, Climeworks Norway and Carbon Removal have received support from Enova for studies on direct air capture (DAC).

Purpose of CDR funding in CLIMIT Demo

There is an increasing need for CDR expertise in industry and research. It is important that CDR solutions (technologies, methods, value chains) are tested and evaluated well before 2050, when these solutions will play a larger role in keeping the temperature increase below the 2-degree target (ref. IPCC).

Norwegian funding instruments, including Enova, the Research Council, Innovation Norway and Gassnova, currently support CCS. However, there is up to now not a specific focus on CDR.

Open call now in 2025

The CLIMIT programme will be able to support industrial projects and research projects in collaboration with industry in the following themes

- BioCCS

- Biochar/biochar with a focus on long-term storage for industrial and possibly agricultural use

- DAC with CCS

- Enhanced Mineralization by injecting CO2 into the bedrock

- Development and evaluation of methodologies in line with EU regulations – to clarify whether a project contributes to carbon removal, such as LCA (Life Cycle Analysis), TEA (Techno-Economic Analysis) and MRV (Measurement/Monitoring-Reporting-Verification).

Applicants are encouraged to explore the possibility of establishing Nordic or international collaborations with industry and/or recognised research institutions.

CLIMIT Summit; 20 Years of Pioneering CO₂ Projects

This year marks the 20th anniversary of the CLIMIT program, celebrated with CLIMIT Summit 2025 at Bølgen Kulturhus in Larvik. From February 25–28, leading experts, industry partners, and researchers will gather to discuss the future of CO2 management technologies.

For two decades, the CLIMIT program has been instrumental in developing Norwegian and international solutions for CO2 management. The program is a collaboration between Gassnova and the Research Council of Norway.

Development, Testing, and Commercialization

Since 2005, CLIMIT has contributed to the development, testing, and commercialization of CO2 management technologies. CLIMIT Summit 2025 will be a key milestone in this journey, providing a platform to discuss the road ahead. With a strong technical program and site visits to various facilities, the conference offers a unique opportunity to network and exchange knowledge across disciplines and borders.

“CLIMIT has enabled research communities and industry to establish close ties to leading research communities internationally, which has in turn improved the quality f their own deliverables. The programme has accelerated technological development in terms of both research and industrial activities, and Norway is now among the world’s leaders in the field of CO2 management. Foreign delegations visit Norway to learn about CO2 management, which is a source of pride and new opportunities for technological development and industrial growth”, says Minister of Energy Terje Aasland.

Dedicated Conference on CDR and Site Visits

This year, CLIMIT Summit includes a dedicated conference on Carbon Dioxide Removal (CDR) in collaboration with Mission Innovationn CDR. There will also be site visits to Longship project stakeholders and the Technology Centre Mongstad (TCM), the world’s largest and most flexible test center for CO2 capture technology verification.

A Platform for Knowledge Sharing

Since its inception in 2010, CLIMIT Summit has grown to attract nearly 350 participants from around the world.

“CLIMIT is a vital driver for sharing knowledge on CO2 management. Over the years, CLIMIT has hosted numerous seminars and conferences where experts have presented research findings and innovative technologies.”

Kari-Lise Rørvik, head of the technology department at Gassnova.20 Years of Technology Development

Since its launch in 2005, CLIMIT has played a central role in the development of CO2 management technologies. The program has supported more than 800 projects focused on research, development, and demonstration of carbon capture and storage (CCS), many of which have led to concrete industrial solutions.

“With a strong focus on innovation, industrial testing, and international collaboration, CLIMIT has helped Norwegian technology gain global recognition”

Arvid Nøttveit, Chair of the CLIMIT program boardCLIMIT and the CO2 Value Chain

CLIMIT has closely collaborated with research institutions, as well as industry partners. The strong link between research and industry has positioned Norway as a global leader in CO2 management. CLIMIT also plays a key role in developing business models for CCS and facilitates cooperation across industrial sectors.

A prime example is Longship, where past CLIMIT-supported projects have been groundbreaking in realizing Norway’s first large-scale CCS project. Longship is also Norway’s largest industrial climate initiative.

As Longship moves into operational phases, valuable insights will be gained, contributing to further cost reductions and technological improvements for future CCS projects.

“CO₂ Safe & Sour”; How pure must CO₂ be for CCS?

A CLIMIT-supported research project under DNV’s leadership is investigating threshold values for impurities, including hydrogen sulphide (H2S), in CO2 handling. Can costs and safety be better balanced?

The project has received funding of over NOK 4.8 million from CLIMIT. DNV is collaborating with Equinor, Shell, TotalEnergies, and Gassco, with the work expected to conclude by summer 2025.

Background

Klas Solberg, DNV’s project manager, explains the origins of the project.

“The background was uncertainty regarding the impact of impurities in CO2 streams, particularly H2S. H2S, when combined with water and other impurities, can lead to corrosion, sulphide stress cracking, and the fracture of pipeline steel. The project was initiated to better understand the tolerance of pipeline materials to H2S, and to determine whether the existing threshold levels are overly conservative.”

Klas Solberg, DNV«Safe & Sour»

In the context of carbon capture and storage (CCS), “safe” refers to ensuring CO2 is handled securely, reducing risks of leaks or harm to the environment and humans. This includes proper design and operation of storage sites. “Sour” is a term from the oil and gas industry related to the presence of H2S, a substance with a foul smell reminiscent of rotten eggs.

Strict purity requirements for CO2 can drive up costs since removing H2S and other impurities is both complex and expensive. The DNV project is exploring whether the limits for H2S can be safely increased, and what material choices are necessary to accommodate H2S presence.

This could make CCS more economically feasible for more stakeholders. The topic is particularly relevant for projects like Longship, where pipelines are a critical part of the infrastructure. By understanding how H2S affects materials, this research project aims to contribute to updated and more cost-effective design and operational standards.

Objectives

The project’s recommendations will be used to update DNV’s Recommended Practice – DNV-RP-F104: Design and Operation of Carbon Dioxide Pipelines. – This guidance is used by the industry for the design and operation of CO2 pipelines. We aim to provide the industry with tools to balance safety and cost effectively, Klas Solberg says.

Joint Industry Project

– The project operates as a ‘Joint Industry Project,’ where we collaborate with stakeholders across the CCS value chain. Partners like IFE, Wood, and DNV USA contribute their expertise in material testing and analysis, Klas explains. The primary focus is testing what concentrations of H2S can be tolerated without damaging pipelines.

The project also leverages experience from the oil and gas industry, applying established methods and knowledge to address CCS challenges. – By combining knowledge and experience across sectors, we can contribute to a safe and cost-effective framework for CCS. Norway, as an energy nation, has many significant advantages, which this DNV project capitalizes on. In turn, it makes CCS more accessible to global stakeholders, enabling knowledge sharing beyond borders, says Ernst Petter Axelsen. He is Gassnova’s advisor in the DNV project, which is part of CLIMIT’s contribution.

CLIMIT provides legitimacy

– Broad and trusted collaboration is critical for a project like this, says Klas Solberg. DNV plays a key role as a facilitator and independent party, helping industry partners reach a common understanding, and develop standards and practices acceptable to the entire industry. CLIMIT’s support enhances the project’s legitimacy, particularly internationally.

“The strong collaboration between government and industry in Norway garners positive attention. Early CLIMIT support was crucial to getting the project off the ground.”

Klas Solberg, DNVResults so far

– To date, we have developed test procedures that identify mechanisms causing pipeline damage from high H2S concentrations. This has provided valuable insights into how materials are affected under different conditions. Although the experimental work is ongoing, the project has already established an important foundation for further research and development.

The recommendations so far offer the industry new perspectives on managing H2S in CO2 streams, Klas Solberg concludes.

Gassnova has covered related topics in articles such as Low-Pressure CO2; Greater Transport Volumes and Increased Capacity and CO2 Transport; Norwegian Expertise Sets Impurity Limits.

CO₂ Storage; The Project Providing the Grand Overview

The project with the extensive title “Multiscale Pressure-Stress Impacts on Fault Integrity for Multi-site Regional CO2 Storage” – referred to as MuPSI, aims to address challenges related to pressure impact and infrastructure sharing in broadly developed geological formations.

As part of the energy transition, this project focuses on developing safe, efficient solutions capable of meeting climate goals on a gigaton scale. NORCE Research Director and Adjunct Professor Sarah Gasda explains the objectives of the MuPSI project. Together with scientific findings presented at the GHGT-17 conference in Calgary, she provides an overview of MuPSI’s work on pressure management and risk minimization in CO2 storage.

The CLIMIT programme has invested in international collaboration for many years. Initially through Accelerating CCS Technologies (ACT), and now through a new international partnership, the Clean Energy Transition Partnership (CETP). The MuPSI project is supported through CETP, meaning that Norwegian partners receive financial support from CLIMIT, while foreign partners are funded by agencies in their respective countries.

Background and Main Objectives of MuPSI

The MuPSI project is organized in collaboration with partners from the United States, Scotland, Spain, and the Netherlands – where technical expertise and experience are shared to develop standardized and scalable solutions. The Norwegian portion of the project begins at the start of the new year. Sarah Gasda emphasizes that MuPSI’s technical aspects are demanding, and good teamwork is essential for safe implementation of these methods.

MuPSI is designed to enable carbon storage at a gigaton scale, necessary to meet the international climate goals set by the IPCC. Achieving this scale requires developing shared CO2 hubs, allowing multiple stakeholders to utilize common storage areas and surface infrastructure cost-effectively. Such hubs could also reduce logistical costs and simplify the overall management of CO2 storage. At the same time, sharing storage infrastructure introduces new challenges, as pressure increases from one actor could impact neighbouring licenses. This can create complex ripple effects requiring careful risk management, monitoring, and modelling.

Technological and Geological Challenges

CCS relies on the ability to securely store CO2 in underground formations. The MuPSI project focuses particularly on how CO2 injection pressure can be managed when multiple actors, operate within the same area. Gasda describes how aging storage fields, the development of renewable energy sources, and the integration of sustainable solutions are central to MuPSI.

– We must ensure that technical and environmental requirements are met in all aspects of storage, says Gasda. This entails thorough testing and modelling to ensure safe and reliable storage over time.

Research shows that pressure from CO2 injection can move faster and over greater distances. This is a critical factor, as pressure displacement can affect nearby licenses – potentially reducing available storage capacity due to increased risk of leakage and seismic events.

MuPSI is developing hierarchical models that combine regional pressure and stress analysis with detailed local simulations. This enables monitoring of pressure conditions across larger areas, while accounting for specific geological features at the local level. This is essential for evaluating the risks associated with pressure increases, giving operators an accurate assessment of how much CO2 they can safely inject, without negatively impacting other stakeholders in the area.

Infrastructure and Pressure Impact

According to Gasda, one of the benefits of considering overarching infrastructure for CO2 storage, is that it enables injection and storage of large amounts of CO2 from multiple actors in a cost-effective manner.

Northern Lights is an example of how shared resources can be used for CO2 injection. Northern Lights acts as a hub that can receive CO2 from multiple sources, and store it in underground formations in the North Sea. Such hubs require advanced pressure management models, as pressure from one actor may influence the capacity plans of neighbouring licenses.

The MuPSI project examines how CO2 injections from multiple actors in the same area can lead to overlapping pressure zones, which could affect the storage capacity of different stakeholders. – In practice, this means neighbouring injections could impact the capacity an operator believes they have available, Gasda continues. If one actor has sold storage capacity and later discovers that neighbouring injections alter pressure conditions, it may be necessary to adjust agreements. To reduce the risk of unforeseen changes in capacity, MuPSI views the entire region as a single resource, planning storage capacity as a unified entity. This approach facilitates better risk management, cost control, and long-term, purposeful planning.

Experience from Oil and Gas Activities

In addition to new CO2 injections, MuPSI must consider previous oil and gas activity in the area. According to Gasda, pressure changes resulting from oil and gas production can affect how much CO2 can be safely stored over time. Research shows that geological formations previously exposed to extraction, may have entirely different pressure conditions than undeveloped areas.

– This is especially true in areas where large amounts of hydrocarbons have been extracted, Gasda explains. She notes that pressure conditions in such fields may require customized models, to understand the changes that occur when new CO2 injections begin in the same area.

Long-term Predictions and Risk Management

Sarah Gasda explains that the prediction timeframe in MuPSI spans several decades, which is essential for a project aiming to store large amounts of CO2 over time. – With a thorough understanding of the geology, we can develop predictions that provide a realistic picture of future pressure conditions, covering all potential scenarios, she says. Research shows that long-term models offer more robust planning support, allowing stakeholders to base decisions on more reliable forecasts.

International Collaboration and Knowledge Sharing

DInternational collaboration in the MuPSI project is essential. Gasda emphasizes the value of working with partners from, among others, Scotland and the United States. Scottish partners contribute expertise in geomechanics and field measurements. Research partners from Spain bring strong theoretical knowledge. They participate to learn from the project and build their knowledge of CO2 storage. – For the Spanish, this is an opportunity to learn from our experience with real models and projects, gaining practical insights that could support CO2 storage projects in Southern Europe, where this technology is less developed, she says.

The MuPSI project facilitates the exchange of technical insights that could have broad international applications. By using case studies and comparative data from the United Kingdom, MuPSI can analyse different geological structures’ responses to CO2 storage under varying conditions. This provides valuable insights into which solutions may be most effective in various regions.

Longship and Northern Lights

MuPSI is relevant to Northern Lights, a hub for offshore CO2 injection in Norway – and an important part of the Longship project. Gasda points out that MuPSI aims to provide insights into how activities by other operators might impact licenses around the Northern Lights area.

– Our work provides insights into planning and ensuring optimal use of shared infrastructure on a large scale, Gasda explains. This helps maximize resource utilization while reducing the risk of one operator’s activities negatively impacting another.

MuPSI’s work on pressure management is a key piece in scaling carbon storage to gigaton levels. By developing a structure that grants all stakeholders access to reliable, up-to-date information on pressure conditions, MuPSI contributes to making carbon capture and storage even safer and more efficient.

New CLIMIT and CETP calls for proposals

The Research Council of Norway’s part of the CLIMIT programme announces NOK 70 million in 2025 for projects that can promote the development of CCS (CO2 Capture and storage).

The main objective of CLIMIT is to contribute to the development of technologies and solutions for CCS. The programme funds research, development and innovation that can contribute to the long-term development of CCS as a climate measure where giga tonnes of CO2 are captured and stored worldwide.

The Research Council’s part of the CLIMIT programme will provide funding for the following calls for proposals in autumn 2024 and throughout 2025:

| Call for proposals | Available funding | Application deadline | Link to calls for proposals |

| International projects through the CETP Joint Call 2024 | NOK 40 million | 21 November 2024 | Link |

| Collaborative projects (KSP-S) | NOK 40 million | 5 March 2025 | Link |

| International projects through the CETP Joint Call 2025 | NOK 30 million | Autumn 2025 | The Call will be published on the CETP website spring 2025 |

In addition, Gassnova’s CLIMIT-demo programme will also have a call for proposals in 2025. More details on the opportunities through Gassnova’s part of CLIMIT can be found here.

Limited budget

CLIMIT has a limited budget and therefore only collaborative and international projects will be prioritized in 2025.

This means that there will be no earmarked funding for CCS in the Research Council’s calls for Innovation Projects (IPN) and Knowledge-building Projects (KSP-K) in 2025.

Applicants interested in innovation projects are referred to the CLIMIT-Demo call.

Collaborative projects

CLIMIT har i en årrekke prioritert utlysning av kompetanseprosjekter (KSP-K), samtidig som det er flere år siden CLIMIT hadde For several years now, CLIMIT has prioritized calls for Knowledge-building Projects (KSP-K), while it has been several years since CLIMIT had a call for Research Projects. As a result, the share of basic research in the CLIMIT portfolio has been declining for several years. In 2025, Collaborative Projects (KSP-S) will therefore be announced, which will be open to applications for new concepts. The aim of this prioritization is to increase the share of basic research in the CLIMIT portfolio.

Important features of KSP-S are

- The projects develop new knowledge and build research expertise needed by society and/or industry to address major societal challenges.

- The projects are at or close to the state of the art.

- Projects must have at least two Norwegian partners who are not research organizations. These must be societal or business actors who contribute experience and knowledge and ensure that the project and its objectives address relevant challenges. The application must demonstrate that at least 10 percent of the total project costs will be allocated to these partners. However, there is no requirement for cash contributions from industry partners.

Further details on collaborative projects are available on the Research Council’s website.

CETP international calls for proposals

International RD&D collaboration is important for the successful implementation of large-scale CCS. The Clean Energy Transition Partnership (CETP) has annual calls for RD&D proposals. Applications must include partners from at least three of the countries participating in CETP.

The CETP 2024 call for proposals has deadline for submitting pre-proposals 21 November 2024.

The CETP 2025 call for proposals will be published in spring 2025 with deadline for submitting pre-proposals in November 2025.

How to contact us

Please contact Aage Stangeland at the Research Council of Norway if you have any questions.

CLIMIT; “The Sediment Detective” Finding Better CO₂ Storage

By combining mineral analyses from cuttings with Information from well logs, researcher Brit Thyberg and her partners are developing knowledge that will enable even safer CO2 storage.

The goal is to reduce both risk and cost while increasing understanding of the caprock on the Norwegian Continental Shelf (NCS). The project is supported by CLIMIT with 400,000 NOK. Gassnova’s CLIMIT representative Ernst Petter Axelsen is the project’s advisor.

Objective

A central goal is to reduce the risk and costs associated with CO2 storage. By increasing understanding of how the sediments and caprock behave during CO2 injection, the risk of leakage can be reduced, ensuring safe and efficient gas storage. This contributes to predictability and fewer incidents that could lead to unforeseen expenses. The quality or integrity of the caprock is critical for safe, permanent, and reliable CO2 storage in the subsurface.

By developing and testing a new model of how sediments change their properties over time, Brit Thyberg hopes to predict which areas are best suited for CO2 storage. The aim is to subdivide the subsurface into systems and identify which areas and intervals have caprock of sufficient quality. This contributes to safe and efficient injection and storage of CO2.

– The knowledge from this project can be utilized to develop AI algorithms, digital maps, or atlases, allowing us to predict the systems and utilize this information actively in our analyses and decision-making processes in real time, says Brit, who encourage collaboration on this work.

A Natural Laboratory

– We are lucky to work with the geology of the North Sea, as we have a natural laboratory with regional and stratigraphic variations, providing an excellent opportunity to study the complex processes that affect the composition of sediments in the subsurface, says Brit Thyberg. She explains that these sediments represent both opportunities and challenges.

The Cenozoic overburden in the North Sea consists of several different sedimentary units. This includes Paleogene marine swelling clays, sandy turbidites and injectites/synkites, and Neogene deltaic sand as well as offshore marine clays. Although these variations represent opportunities for CO2 storage reservoirs in the Cenozoic, they also pose challenges related to the sealing capacity of clays and claystones of the caprock. Clays and claystones mainly consist of different types of clay minerals (e.g. smectite, illite, chlorite, kaolinite), as well as silt, biogenic, and organic material. The primary composition varies depending on erosion from different source areas, climate, depositional environment, and variations in the supply of volcanic and clastic material. Variations in mineralogical composition can affect how the sediments respond to increasing pressure and temperature with greater burial depth. The regional and stratigraphic variations make it particularly important to understand the density and sealing capacity of clays and claystones above the reservoirs.

To predict which areas and intervals have favourable caprock properties for CO2 storage, Brit emphasizes the importance of regional understanding and mapping.

Dedicated Professional Innovator

For over 20 years, Brit Thyberg has been engaged in the study of North Sea geology, digitalization, technology development, and exploration, often at the forefront of innovation. – With a PhD in “overburden” focusing on clays and claystones in the North Sea, I see a great potential to systematize and utilize this knowledge for CO2 storage.

Brit’s career in clay research began in the mid-1990s when she was involved as a doctoral research fellow in an extensive EU project led by Professor Knut Bjørlykke at the University of Oslo. The aim was to integrate mineral data from cuttings with seismic and well logs to better understand the Cenozoic overburden in the North Sea. The interdisciplinary approach and integration of multiple data types in a large regional project was innovative. – What was new was also the expansion of our knowledge base on the composition of sediments in the shallower Cenozoic overburden in the North Sea. At that time, the focus was primarily on oil, gas, and the properties of deeper reservoir rocks, says Brit. She adds that the University of Oslo’s Department of Geosciences became, in many ways is a centre of expertise on clays and claystones through several major research projects.

Caprock Quality

In the large EU project, we found that clay minerals have different chemical and physical properties that influence the compaction degree of claystones in the subsurface. For example, we documented that coarse-grained glacial Pliocene clay undergoes relatively rapid mechanical compaction, whereas fine-grained Eocene smectite-rich clays derived from volcanic material, or fine-grained Pliocene marine smectite-rich clays, compact much more slowly. We also found a regionally extensive clay layer consisting of a mix of diatoms and clay minerals from the Oligocene in the northern North Sea, says Brit.

Diatoms are small, microscopic organisms composed of silica. When mixed with clay, the properties of sediments change, including their ability to function as a sealing layer for CO2 storage. However, these rock properties change with increasing burial depth. Professor Bjørg Stabell also discovered a -new- diatom species in the North Sea, named after Brit Thyberg: – Paralia Thybergii. The microfossil resembles the Colosseum in miniature.

Brit points out how different types of clay can influence the density of the caprock. The caprock must be dense enough to contain the gas but also be able to adapt to mechanical pressure and chemical changes without fracturing. – For instance, the presence of diatoms in clays and claystones can change the quality of the caprock, affecting how well it retains CO2.

By understanding how clay, diatoms, and various clay minerals affect the caprock properties, researchers can better predict which areas are most suitable for CO2 storage.

In 2012, Brit and her former colleague Professor Jens Jahren received a research award for their work on clay research. Brit combined geology with knowledge from network theory, which she had previously learned during her master’s in technology management, allowing us to view clays and claytones “with new eyes”. The findings from this research have significant relevance to Brit’s work on the CLIMIT project. The major collaborative industry project “NOROG Digital Cuttings” has also played an important role.

Data Digitalization

In 2018, the industry initiated a comprehensive three-year collaboration to digitalize cuttings data, which had previously only been stored, for example, at the Norwegian Offshore Directorate. Cuttings are small pieces of the subsurface taken out during well drilling. Over 700,000 samples from 1,934 exploration wells on the Norwegian Continental Shelf were digitalized and analysed. – The samples provide valuable information about the composition of the subsurface, particularly regarding sediment composition and intervals that may be relevant for CO2 storage, says Brit. She compares the process to drilling through a wall: – First you hit the wallpaper, then the gypsum board, and then the brick, with different material composition. In the same way, we utilize cuttings to analyse the differences in the composition of layers in the subsurface and obtain information about what is deposited. Cuttings provide researchers with insight into the entire drilling interval, not just intervals where cores have been taken. The digitalization project opened a new landscape for research and understanding of the subsurface, particularly of the shallower layers relevant for CO2 storage in the North Sea. Several operators and vendors on the NCS have incorporated the large dataset into their digital solutions. Further development and integration of cuttings data will be an important part of Brit Thyberg’s work to enhance knowledge about the properties of caprocks.

In the CLIMIT project, Brit utilized the data to screen for wells with clay-rich diatom layers, similar to those found in the 1990s. It turns out that many of these NOROG wells contain the mix of clay and diatoms in specific layers, including in several wells near current CCS licenses on the NCS. Increased knowledge of clay and its mechanical and chemical compaction can be useful for various projects, from infrastructure development to safe waste storage, offshore wind, and the green transition within oil and gas.

The Road Ahead

Business development has its challenges, especially in securing ownership of one’s work. To establish agreements and secure commercial ownership, Brit says it feels reassuring to have advice from Ernst Petter Axelsen and CLIMIT supporting her. – I have already experienced that having CLIMIT on board strengthens the integrity of the project. This will be important going forward, especially in dialogue with potential industry partners and collaborators, says Brit. By continuing the work, she hopes to develop innovative models, systems, and AI algorithms that provide even better understanding of how the subsurface can be utilized for CO2 storage. Brit Thyberg’s driving force is to make CO2 storage even safer and more cost-effective, and increase the knowledge about the caprock, based on research-driven innovation.

CLIMIT; Testing of Mass-flow meters for CO₂

Cignus Instruments AS is developing a patented concept for mass flow measurement of liquids and gases, offering technological advantages particularly relevant for the CCS value chain.

The demand for accurate and scalable mass flow measurement, like from Cignus Instruments, in CCS projects is significant, as current technology does not fully meet the industry’s specific requirements. Traditional Coriolis meters face challenges when scaled up to larger dimensions and when operating under high pressure. Additionally, Coriolis technology can result in significant internal pressure drops, which can cause issues when measuring liquids near their boiling point, thereby increasing measurement uncertainty.

The project is supported by CLIMIT with NOK 1.7 million. Founder and CEO Martin Nese is the project manager at Cignus Instruments AS.

Objective

Aim of the project is to demonstrate the advantages of Cignus technology in large-scale CCS facilities. The technology offers a more accurate and simpler method for mass-flow metering of CO2. – We conducted a test campaign at Equinor’s P-Lab at Herøya, Porsgrunn. Here we observed that the pressure drop through the Cignus meter was limited to about one-tenth of that through a straight-tube Coriolis meter, with the same capacity, says Martin Nese.

– Low, permanent pressure drop is particularly important for reducing the risk of boiling – and thus minimizing measurement uncertainty when measuring CO2 in liquid phase. Lower pressure drop means lower energy consumption, highlighting the potential for Cignus technology in large-scale applications.

Project Deliverables

The prototype demonstrated the functionality and accuracy of the Cignus Mass-flow meter for CO2 in gas, liquid, and supercritical phases under relevant industrial conditions. The test campaign at Equinor’s P-Lab was initially scheduled for Q1 2023, but was postponed to October of the same year. This delay provided more time to characterize and conduct various tests on the CO2 prototype.

The prototype has now been tested with the correct medium in an installation that closely resembles a real process plant, demonstrating that the instrument performs as expected, even when the load varies over a wide range. When measuring mass flow and fluid density, the Cignus meter’s accuracy is comparable to Coriolis meters installed in series.

Scaling Up

The next step in development is building and qualifying a full-size CO2 meter, with a capacity of 1,000 tons/hour and a design pressure of 300 bar for installation in a large-scale CCS pilot plant by 2026. – We plan to test the technology in a full-scale installation as early as possible to gather as much field experience as possible under continuous operation. At the same time, we will establish a supply chain and capacity to produce the final product for large-scale CCS applications starting in 2026, explains Martin Nese. This will be a significant step forward, not just for Cignus but for the entire CCS industry. By providing a more accurate and reliable method for measuring CO2, particularly in large pipelines and under challenging operating conditions, the technology has the potential to become an industry standard.

Well-Positioned

– Cignus Instruments is well-positioned to lead the development of the next generation of Mass-flow meters, with special focus on the CCS industry. We also see great potential in implementing such meters subsea, where it is crucial to know the exact amount of CO2 distributed to each well. All of this points to an exciting future for Cignus Instruments and their contribution to global CO2 reduction, says Ernst Petter Axelsen, Gassnova’s representative in the CLIMIT program and advisor to the Cignus project.

Future Prospects

– We plan to produce the meters in collaboration with suppliers in the Stavanger area, who have experience from the oil and gas industry. In the long term, we also see potential for collaboration with DNV, which is establishing a commercial calibration lab for CO2 meters in the Netherlands. This will give us the opportunity to offer large-scale calibration services, which is essential for gaining the necessary trust in the industry, Martin continues.

Martin also discusses opportunities to expand the business model. – We are considering offering data collection services as part of our business model, rather than just delivering the instruments themselves. This is something we will explore further when we have a fully qualified product. We believe that access to real-time data and the ability to perform health checks on the instruments during operation, could be valuable services for our customers.

Regarding international cooperation, Martin explains that they are collaborating with several entities, both in Norway and internationally. – Norway is a leader in CO2 storage technology, and there is an expectation that insights from Norwegian CCS projects will be shared internationally, especially in Europe. Therefore, Cignus Instruments is looking at opportunities to expand internationally, leveraging several upcoming reference projects.

CLIMIT: Acoustic Shockwave Technology for CO₂ Storage

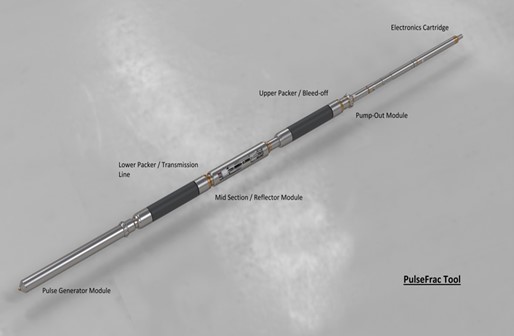

The company qWave is developing a new method for measuring horizontal stresses in the caprock during CO2 storage projects.

This technology has the potential to enhance both the safety and the economics of CO2 storage. The project is supported by CLIMIT with just under NOK 4.8 million. Jan Ove Nesvik, CEO of qWave, is responsible for the project.

Safety and Economics

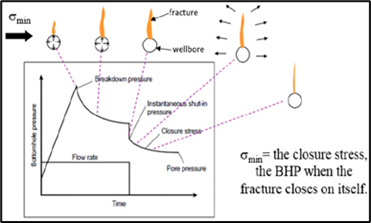

Effective and safe CO2 storage requires a solid understanding of the horizontal stresses in the caprock, which serves as a sealing element to prevent leakage from storage reservoirs. Caprock is a critical component in these projects, preventing CO2 from migrating out of the storage areas. To assess how much CO2 can be injected, it’s crucial to understand the stresses affecting the rocks. A better understanding of the caprock’s properties can help increase CO2 injection volumes per well. By minimizing the risk of leakage, this will reduce storage costs and improve safety.

Current methods for measuring horizontal stresses, such as the Leak-Off Test (LOT) and the use of straddle packers, have several limitations. These methods can produce unreliable results, requiring repeated measurements to ensure accurate data. This becomes especially challenging in deepwater environments, where costs escalate rapidly. The existing solutions are also limited to certain depths and may be inadequate as stress levels in the rock formation can vary with depth. Thus, it is challenging to provide an accurate assessment of storage properties, making projects both costly and complex.

Inspired by Medical Science

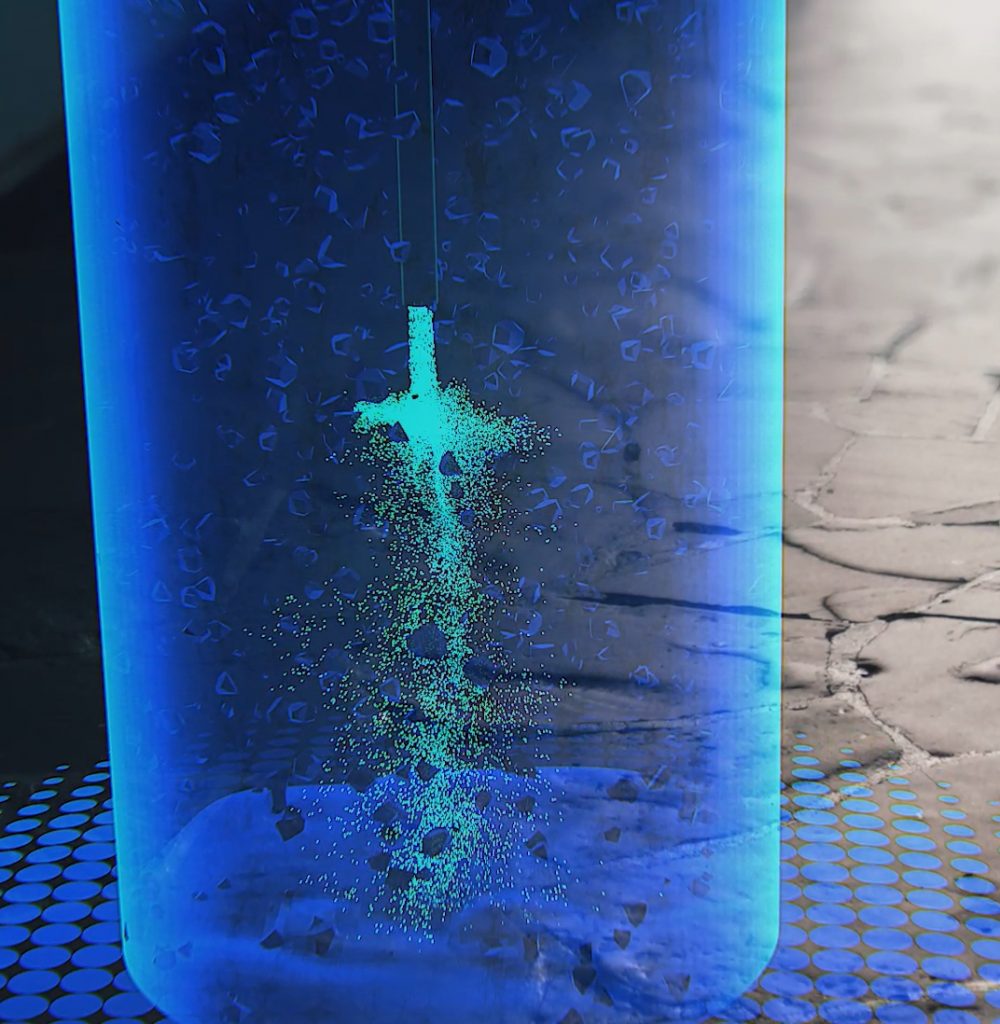

qWave has drawn inspiration from medical technology, particularly Extracorporeal Shock Wave Lithotripsy (ESWL), which is used to break kidney stones using acoustic shockwaves without surgical intervention. By transferring the principles from ESWL to well technology, qWave has developed a method using focused shockwaves to create a weak point in the rock formation, enabling more precise measurement of horizontal stresses necessary to assess CO2 storage capacity. The technology includes a shockwave generator with a capacity of up to 30,000 volts. By focusing the shockwaves, qWave is able to create a perforation several centimetres deep in the borehole wall. A custom pump and equipment are used to fracture the formation where the perforation is made, and then gradually close it again until the minimum horizontal stress is measured. This allows qWave to perform better measurements in less time.

The technology has already shown promising results. The prototype has been successfully tested. The shockwave technology was developed in collaboration with Harald Eizenhöfer, former Research Director at Dornier MedTech Systems GmbH, and Hartlauer Präzisions Elektronik GmbH. The first demonstration of the prototype took place in September 2023 at NORCE/Ullrigg in Stavanger, where the tool proved to be both robust and functional under realistic well conditions. A second demonstration in November 2023 confirmed this impression.

Industry Partnership

qWave has established a Joint Industry Project with industry partners including Equinor, Vår Energi, DNO, and OMV. These companies contribute expertise and funding, while also defining technology needs and development goals. The partners see potential in qWave’s technology – not only to improve safety and cost-efficiency in CO2 storage projects, but also for applications in oil and gas drilling.

The next major milestone for qWave and its industry partners is to demonstrate the technology in an offshore well. This is an important step toward commercializing the technology. A successful offshore demonstration will also help build confidence in the technology and open up further market opportunities – both in Norway and internationally. Several more tests and demonstrations are being considered before the technology is demonstrated offshore.

– CLIMIT’s contribution has been crucial for our project. The support for demonstrating the technology has contributed to the development of an advanced prototype, and enabled extensive testing at NORCE’s test center in Stavanger. Such tests are costly but essential, to show that the technology being developed and tested in qLab also operates as expected under well-like conditions. Most importantly, we are learning and acquiring knowledge we didn’t have before, says Jan Ove Nesvik of qWave.

– With a strong commitment to innovation, collaboration, and a focus on meeting industry standards, qWave is positioned to make a significant difference. The further development and commercialization of this technology will be an important step forward for sustainable and safe CO2 storage solutions. Focus on innovation and partnerships could set new standards in the industry, says Kirsten Haaberg, Gassnova’s representative in CLIMIT and advisor to the project.

The Road Ahead

The plan is to develop a commercial 2.0 version of the tool, which will offer even better solutions for measuring horizontal stresses in wells. This could become the standard for both CO2 storage projects and oil and gas drilling. Goal is to improve safety and efficiency, representing a significant advancement in geomechanically analysis.

Is CLIMIT’s Effort Bearing Fruit?

What impact does the CLIMIT program have on Norway’s work with carbon capture and storage (CCS), and what challenges are emerging in the wake of the Longship project?

In this interview, Arvid Nøttveit, Chair of the CLIMIT Program Board, shares his reflections on the development of CLIMIT, its current significance, and the future outlook for the program.

Concrete Results

For many years, the CLIMIT program has been a central player in Norway’s efforts in carbon capture and storage (CCS). With its long history and influence both nationally and internationally, the program has helped position Norway as a leader in CCS technology.

– CLIMIT has received much attention, and rightly so. The attention is not only a result of the program’s success but also of a conscious effort to effectively highlight the results, says Arvid Nøttveit.

A few years ago, significant changes were made to CLIMIT’s website with the aim of increasing transparency. Now, anyone can easily get an overview of how many projects are ongoing, which ones have been completed, and what they have achieved. This increased visibility has had a positive effect on the program’s grantees. – When those who receive support see their work is being documented, recognized, and shared, it contributes to a sense of pride. It is important for CLIMIT to showcase real results and ensure these results are noticed both nationally and internationally, he explains.

Communicating research results and technological developments to a broader audience is often challenging, especially when the technology being developed is complex. – Often, millimetre precision must be balanced with the message to be conveyed. ‘Simplify without oversimplifying’ is an important mantra in our communication. It’s about making complex technologies understandable to the public without losing technical nuances.

The Programme Plan

Nøttveit describes CLIMIT’s program plan as a solid strategic document that provides direction and structure for the program board. – The big idea behind the program plan is to have a document that helps plan future projects and assess new proposals. Arvid further explains that the program plan serves as a reference when new project applications come in. – If a project falls outside the plan’s scope, it cannot be supported. For applications on the borderline, longer discussions in the program board are often required to determine if they should be supported. Thus, this plan serves as both a ‘guiding star’ and a practical tool in the decision-making process.

Although the program plan is revised regularly, typically every three or four years, Nøttveit emphasizes the importance of ensuring the plan remains relevant in a constantly changing world. New technologies and trends are considered when the plan is updated, making it a living document that continuously adapts to the external environment. – The program plan is not just a theoretical document but something we actively use to ensure that the projects we support align with our strategic goals.

The current program plan was developed in 2021 and remains strong, according to Nøttveit. While some concepts have become more relevant in recent years, such as direct air capture (DAC), the main structure is solid. – As we review the plan, we will consider how we can adapt it to the latest research, technological developments, and innovations. I believe the main structure will remain intact. CLIMIT has always been proactive in relation to technological advancements, and it is this proactivity that ensures the plan remains relevant.

Predictable Frameworks

Funding is another important factor. Nøttveit points out that CLIMIT has managed to maintain a stable financial situation over time, despite budget cuts that all research programs experience from time to time. Periods of smaller budgets have affected the funding of basic research, innovation projects, and larger demonstration projects. Stability is crucial for CLIMIT to continue building strong competence environments and driving long-term technology development.

– Predictability in funding makes it possible to plan long-term, which is one of the main reasons CLIMIT has been so successful, he says.

– Many countries have had periods of major investments, but these have often been followed by periods of cuts or complete halts in research efforts.

Achievements

When the conversation turns to specific achievements, Nøttveit highlights the Longship project as CLIMIT’s largest so far. Although CLIMIT cannot take all the credit for Longship, they have played a significant role in supporting the research and technology development that made the project possible.

– Longship is a major milestone for Norway, and it has had an inspiring effect internationally. Collaboration between the government, private sector, and research institutions has been a key factor in the success. This is something special for Norway, he says.

The cooperation between various actors in Norway is unique and crucial for the success of projects like Longship. – In this country, we have a culture of working together towards common goals. This has given us great advantages, especially in large projects like Longship. He believes that the government has been good at listening to the different actors in the process, which has resulted in decisions that have gained support from both industrial, academic, and governmental sectors. – I think this collaboration is one of the main reasons why Norway has been so successful with Longship and other similar projects, he adds.

CLIMIT’s influence does not stop at Norway’s borders. The program also has global influence and is well-known worldwide among those working with CCS. – We have strong ties to research and technology communities in other countries, especially in Europe, says Nøttveit. Through its long history and solid results, CLIMIT is seen as a leading player in the field and attracts interest from around the world. – When we organize conferences or participate in international forums, we see great interest in the work we do. We have participants from all over the world who want to learn from our experiences.

The Future

Despite the successes, Nøttveit also sees challenges for the future. One of the biggest challenges will be maintaining financial stability. – For CLIMIT, it will be crucial to ensure continued predictable and stable funding to continue supporting the important projects the program works with.

Another challenge is keeping pace with the rapid technological development. World is changing quickly, and new technologies and methods are constantly emerging. CLIMIT must be flexible enough to adapt to changes and ensure the program always supports the most relevant and groundbreaking projects.

When it comes to addressing these challenges, Nøttveit emphasizes the importance of continuing to advocate for the significance of CLIMIT, both nationally and internationally.

– We work closely with the government to ensure they understand the value CLIMIT brings to Norway and the global community, he says. In addition, CLIMIT is in dialogue with private actors to explore opportunities for collaboration and co-financing of projects. – Technologically, it is important to ensure that we have the right people with the right expertise in the program. We must be able to identify and support the technologies with the greatest potential, and we must be flexible enough to adapt when new opportunities arise.

CLIMIT’s great strength lies in the combination of stability and flexibility. This enables the program to support both large, long-term projects like Longship and smaller, innovative projects that can grow over time. The strong collaboration with both national and international actors, provides access to a broad range of resources and expertise, which enhances the quality of the projects supported.

Nøttveit is convinced that CLIMIT will continue to play an important role in Norway’s carbon capture and storage strategy. – CLIMIT has been a key player here, and I see no reason for this to change. As technology and the market evolve, CLIMIT will also evolve. We will continue to be a catalyst for innovation and technology development, and we will play a central role in Norway’s efforts to reduce greenhouse gas emissions.

The next major milestones for CLIMIT will be linked to further development of existing technologies, and exploration of new opportunities in carbon capture and storage.

– Technologies such as direct air capture of CO2 will likely receive even more attention in the future, along with projects related to blue hydrogen. We will focus on ensuring that Norway continues to be a leading player in CCS technology – both through projects like Longship and through new initiatives that may emerge, says Nøttveit.

Through targeted research and technology development, the CLIMIT program contributes to reducing greenhouse gas emissions and ensuring a sustainable future. – CLIMIT is a program which delivers real results, and we are determined to continue this important work in the years to come. With the expertise and experience CLIMIT has built up, I am confident that the program will continue to be a leading player in the CCS field, concludes the program board chair.