Kari-Lise Rørvik (45) took over as Head of Secretariat for the CLIMIT programme on 1 November, replacing Ingrid Sørum Melaaen, who has become Technology Director at Gassnova. Rørvik’s ambition is to help keep Norway in the forefront of international research and development and the use of technologies to capture, transport and store CO2.

“But this does not mean that Norway has to be self-sufficient. On the contrary, the continuation of our extensive international cooperation is a prerequisite for our success in combating climate change, with carbon capture and storage as a major policy instrument.”

Seven employees

The CLIMIT programme is a partnership between Gassnova and the Research Council of Norway. The Research Council’s projects are often referred to as CLIMIT R&D, while Gassnova’s contribution is referred to as CLIMIT-Demo. The Secretariat has seven employees, each with a defined responsibility for following up and monitoring the portfolio of research programmes supported by CLIMIT. As Head of Secretariat, Rørvik is responsible for reporting to the Board and for dialogue with the authorities and partners internationally. The activities are managed by a Programme Board with ten members from industry, research institutions and the authorities. The Board carries out an audit of the programme every two years to ensure that the research efforts are up to date in terms of new knowledge and approaches that could provide a basis for developing technology and solutions to meet the needs of society.

Longship a shining example

“The programme was established in 2005 and is aimed at businesses, research institutions, universities and colleges, often in collaboration with international companies and research bodies, which can help to accelerate the commercialisation of CCS. The most tangible result so far is the Longship project, where research efforts supported by CLIMIT and technology testing at Technology Centre Mongstad (TCM) are now enabling industrial-scale capture, transport and storage of CO2 with outstanding technologies.”

Kari-Lise Rørvik points out that CLIMIT provides support for research into the management of all possible CO2 sources, not just point emissions in the industry. Within Energi21, the all-encompassing research and innovation strategy for renewable energy and climate-friendly energy technologies, CLIMIT is responsible for the management of CO2.

Three key areas

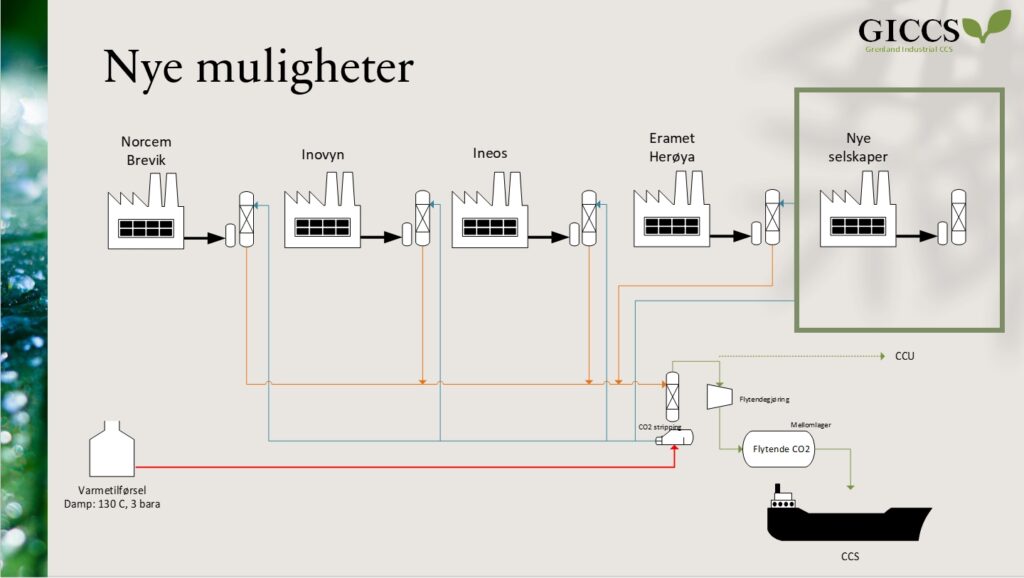

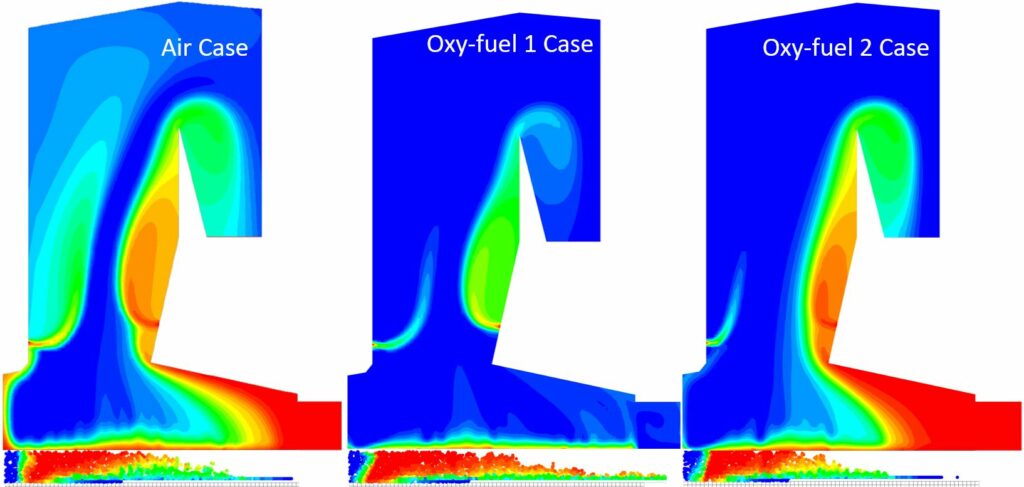

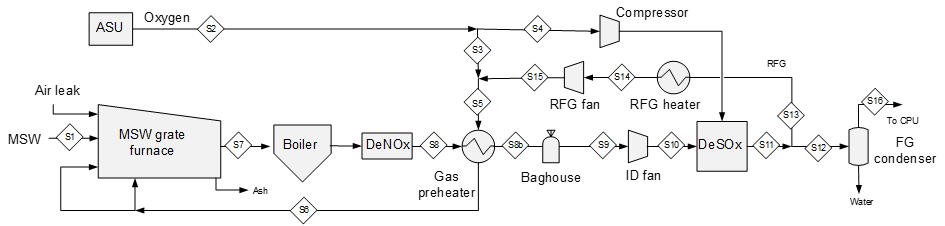

The CLIMIT programme plan for technology development covers three key areas: A. Decarbonisation of industry and energy resources; B. Large-scale CO2 storage on the Norwegian continental shelf; and C. Innovative technology development and solutions.

“Aker Carbon Capture’s development of the solvent to be used to capture CO2 at Heidelberg Materials’s cement factory in Brevik received support from CLIMIT as early as 2005. The way Aker has succeeded in bringing down costs and reducing risk with its technology is very important to the development of the value chain and to value creation related to CCS. The same is true of Northern Lights, which is the first step on the road to creating the infrastructure that both Norway and Europe will need for safe storage of CO2, particularly for monitoring stores in different geological formations. But it is also extremely important to support the development of completely new technologies that could help reduce the cost of managing CO2. In this area, we are collaborating on other parts of the policy apparatus for project financing.”

Here, Rørvik refers to CLIMIT’s collaboration with the Research Council of Norway, Enova, Innovation Norway, Siva and Gassnova on green growth. The aim is to contribute to a quicker path from idea to market for climate-friendly products and services in Norway and around the world.

CCS “breaking through” internationally

After more than six years as a senior adviser on CLIMIT, Kari-Lise Rørvik is now observing significantly greater commitment, both in Europe and in other parts of the world, to making carbon capture and storage part of the climate solution.

“We have worked effectively with several European countries, the USA, Canada and India in ACT (Accelerating CCS Technologies), an initiative that is now being taken further in CETP (Clean Energy Transition) which is part of the Horizon Europe programme. We expect this to lead to even more innovative projects involving Norwegian researchers and technology developers.”

In 2004, Norway signed a bilateral agreement with the USA on research, development and demonstration in the energy field; a collaboration that both TCM and CLIMIT have contributed to and which has led to a number of technology developers coming together across the Atlantic.

Mission Innovation is a global initiative arising out of the Paris Agreement, which works to catalyse action and investment in research, development and demonstration to make clean energy affordable and accessible, on the road to a net-zero society. Here, Norway has undertaken to assist in the development of technologies for Carbon Dioxide Removal (CDR), i.e. the capture and safe storage of CO2 from the atmosphere. The goal is a net reduction of 100 million tonnes of CO2 globally by 2030. This initiative is dependent on the policy apparatus supporting projects which aim to implement CDR.

Will demand more from the business sector

“Given the ambitious targets for reducing greenhouse gas emissions, there will still be a great need for government support for projects to manage CO2 in the coming years. The authorities also have an important role to play in helping universities and colleges to develop the expertise we need, in the form of world-class researchers. At the same time, it is important for the business sector to take its share of the risk that accompanies the development of new technologies. Good interaction between the business sector and funding providers is the key to continued progress with CCS progress,” she says.