New and Improved Overview of CLIMIT Projects

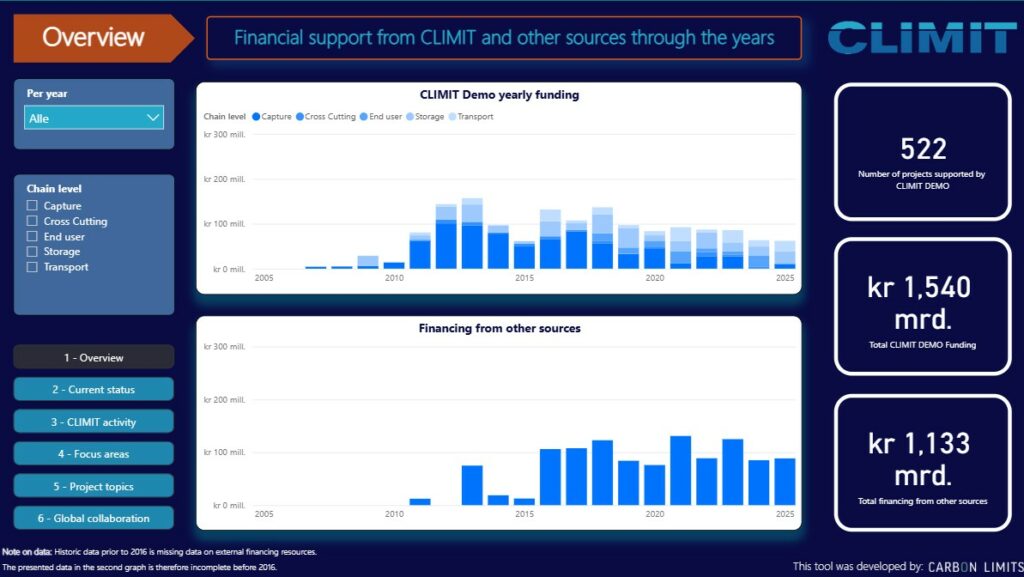

CLIMIT now uses the analysis and visualization tool Power BI to present its project portfolio in a new way.

The solution provides better oversight, up-to-date data, and a clearer presentation of the activities within the CLIMIT programme.

After an extensive development process, CLIMIT has implemented a solution which offers both improved overview and more accessible information about supported projects. The solution has been developed in collaboration with Carbon Limits and consists of an internal tool for the secretariat with access to detailed project data – in addition to a web-based dashboard which gives external users an overview of the portfolio.

New CLIMIT Organization

– The purpose has always been to present CLIMIT’s activities in a more accessible way, says Kristian Stangvik. Kristian joined Gassnova a little over a year ago and now takes over as Head of CLIMIT from Kari-Lise Rørvik. At the same time, CLIMIT is being reorganized. Gassnova’s Board of Directors now assumes the role of the former Programme Board, and makes decisions on the allocation of funding from the CO2 Management Fund, based on recommendations from the Gassnova secretariat. The authority is delegated from the Board to the CEO and further to the Head of the CLIMIT Secretariat. This change contributes to a simpler and clearer decision-making process while maintaining CLIMIT’s professional breadth.

User-Friendliness

Visitors to CLIMIT’s website can now filter projects by year, funding amount, and project category. This provides a clearer overview of which projects have received support and how the programme has evolved over time. Development has also focused on aesthetics.

– We have emphasized improving both the visual design and the user experience, says Kristian.

The external version is not intended as a database of every detail. Rather, it provides a comprehensive and up-to-date presentation of programme activities – including statistics, categories, and timelines. A possible next step is to link the solution to existing project descriptions on climit.no, giving public direct access to more background information.

Dynamic Web Pages

The Power BI solution also enables more proactive communication. If a project receives funding, application rates increase, or unallocated funds remain in the budget, this can be communicated to groups of new projects considering CLIMIT support. – The Power BI tool gives us completely new opportunities. We can now show how the CLIMIT programme evolves in “real time”, month by month, concludes CLIMIT’s new Head, Kristian Stangvik.

The Power BI tool provides a stronger foundation for dialogue with partners, authorities, and potential applicants alike.

Portfolio Analysis and Project Highlights

In 2025, the CLIMIT programme celebrates its 20th anniversary, marking two decades of significant contributions to CCS. The first projects funded in 2005 primarily focused on solvent-based capture solutions. This capture technology remains the most represented within CLIMIT to this day. The CLIMIT Portfolio Analysis 2005–2025 presents the results and impact of CLIMIT’s work since its inception.

On CLIMIT’s website, visitors find a selection of projects offering exclusive insight into the purpose and outcomes following CLIMIT support. These contribute to professional interest while also increasing the visibility of projects through Gassnova’s own channels – websites, reports, lectures, and presentations.

ZEUS Power May Lower CCS Costs

CLIMIT support of NOK 13.1 million enables Aker Solutions to take the next step in developing the zero-emission power plant ZEUS.

The project combines oxyfuel combustion under high pressure with immediate liquefaction of CO2. This is technology that may have major significance for both the Norwegian continental shelf and international gas markets. In this article, ZEUS Program Director at Aker Solutions, Kjartan Pedersen, explains how the solution can create new opportunities.

CLIMIT Support for ZEUS

In January 2024, the CLIMIT program board decided to allocate financial support to Aker Solutions for the Zero Emission Unmanned power Station (ZEUS) project. The funding covers nearly half of the costs for the CLIMIT-Demo project. The development period will last until 2029 – with Petronas and MISC from Malaysia, Clean Energy Systems from the USA, and NTNU as partners.

Technology is based on burning natural gas with pure oxygen under high pressure. When the exhaust is cooled, both water and CO2 become liquid and can be pumped directly back underground. The aim is to test and document a new system for liquefaction and reinjection of CO2.

A Vision for Future Generations

Aker Solutions has long had a clear goal of developing technology which can both meet future energy needs and help reduce emissions. Carbon capture has become an increasingly important part of the strategy. – When we looked into this in depth, we saw that scaling up carbon capture was expensive. We asked the question: How can we lower the costs? says Kjartan Pedersen at Aker Solutions.

Work on ZEUS began in 2014. Since then, the company has matured the idea, worked with customers and other suppliers, and arrived at a holistic concept. It is modular and designed for both offshore and onshore facilities.

Natural Advantages as a Starting Point

Norwegian reservoirs offer good pressure, and offshore areas provide access to cold cooling water. By utilizing these conditions, ZEUS can reduce both the size and cost of equipment.

When gas is burned with oxygen at high pressure, the exhaust – consisting of CO2 and water – condenses to liquid with moderate cooling. – The core of our technology is to burn gas with pure oxygen. This gives an exhaust stream containing only water and CO2. That makes CO2 much easier to capture, and we achieve nearly 100 percent capture. At the same time, it allows us to design compact and flexible power plants, Pedersen explains.

Flexible Balancing Power?

ZEUS essentially functions as a thermal power plant running on gas. Normally, gas burns with air that contains 79 percent nitrogen. When the nitrogen is removed, it must be replaced with 79 percent CO2 to prevent the combustion chamber temperature from becoming too high.

Malaysia has large gas reserves with high CO2 content. ZEUS requires 79 percent CO2 for combustion, making it ideally suited for this market. This is why cooperation has been established with Petronas and MISC in Malaysia. A demo plant is being planned. Among other things, it will test whether ZEUS can function as a balancing power plant, where output can be rapidly increased or decreased. Such flexibility will make the solution attractive in power systems where solar and wind play an increasingly important role.

New Markets for Untapped Gas

For various reasons Europe has gas reserves which are not being utilized today. ZEUS can make it possible to use this gas for power production without emissions. – We may help unlock gas reserves that would otherwise remain unused. This can make Europe more independent of foreign gas without increasing emissions, says Kjartan Pedersen. This opens up new markets – particularly in countries such as the UK and the Netherlands, where electrification from shore is not always economically feasible.

Collaboration with Research

NTNU is a key partner, contributing to test planning and research programs. IFE, for its part, is testing fluid mixtures under high pressure, while suppliers from the aerospace industry are contributing combustion technology. – This is a good example of how offshore expertise can be applied to new, green solutions. If we succeed, much of the technology can be built and delivered from Norway, Kjartan Pedersen says.

“If we can demonstrate that the solution works technically and economically, we can lower the cost level of carbon capture. This will not only help solve climate challenges, but also create growth for Norwegian industry.”

ZEUS Program Director at Aker Solutions, Kjartan PedersenNorwegian Value Creation with Global Climate Gains

Aker Solutions emphasizes that a large share of the design, analysis, and fabrication can take place in Norway. ZEUS will be able to create significant value through engineering expertise, production, service, and maintenance. The project also highlights concrete opportunities for reuse of infrastructure, such as decommissioned platforms and terminals, where ZEUS can be integrated into existing facilities. Thus, climate cuts are combined with cost-efficient utilization of old installations.

The Road Ahead

CLIMIT funding covers nearly half of the costs of ZEUS’ first phase. Going forward, technology will be tested in several thousand operating hours, and the results will be used to validate simulation models and cost estimates.

CCS, Oil and Gas Need Olga

For decades, the simulation tool Olga has been the industry standard for flow assurance in the oil and gas sector. Now, Olga is poised to take on a similar role in the simulation of multiphase CO2 transport.

Olga Prosjektet Robust, Enhanced and Accurate CO2 Handling (REACH), has a budget of NOK 28.2 million. CLIMIT contributes 35.5 percent of the funding. The work is led by SLB – with Equinor, Repsol, Gassco, ENI, BP, Shell and later Chevron og ExxonMobil as partners.

The Olga tool has enabled development of oil and gas fields that were previously considered unprofitable or technically too challenging. Now Olga is approaching a new milestone which involves addressing future needs within carbon capture and storage (CCS). The software is being upgraded to deliver accurate simulations of multiphase CO2 transport, with potential for both technical and economic gains.

From Oil and Gas to CO2 Management

Olga was developed in the 1980s at the Institute for Energy Technology (IFE), in collaboration with Statoil and Sintef. At the time, it was a groundbreaking tool for simulating complex multiphase flows in pipelines and wells – where oil, gas, and water move simultaneously. Responsibility was later taken over by Scandpower Petroleum Technology, which was subsequently acquired by SLB (Schlumberger).

In recent years, Olga has gained functionality for CO2 transport. This has been achieved through a series of research and development projects, several of them supported by the CLIMIT program. As early as 2009, the first feature for modelling pure CO2 was introduced.

“To realize large-scale CCS solutions, we must be able to simulate the transport and injection of CO2 with high precision, both in single-phase and multiphase conditions. That is the key to reducing risk and costs”

Technology Manager Norbert Hoyer at SLBOlga – The Next Chapter

Building on the experience of earlier projects, Olga REACH was launched in 2022.

The goal is to develop Olga to handle multiphase CO2 transport, with the same robustness and accuracy the tool already provides for oil and gas. This entails further development of the software’s very core, its system of equations. In addition, come upgrades to the thermodynamic and hydraulic models used to describe flow. The new functionality will be validated through extensive testing against laboratory and field data. – We want to close the technology gap that has so far limited multiphase simulation of CO2. Olga must be a tool the industry can rely on, even when transport occurs under demanding conditions, says SLB’s Principal Scientific Computing Engineer, Alexandre Brigadeau.

Multiphase CO2 Could Be a Key

In today’s CCS projects, CO2 is usually transported in a single phase – either as a liquid, a supercritical fluid, or in some cases as gas. Allowing multiphase transport makes it possible to reduce pressure without losing flow control, potentially yielding significant cost savings.

Multiphase transport also offers advantages when injecting into low-pressure reservoirs. If liquid CO2 is injected into a warm gas-filled reservoir, the gas will expand, and the temperature will drop sharply due to the Joule-Thomson effect. This can create large geomechanically stresses in the reservoir. By operating in multiphase conditions, the most extreme temperature drops can be avoided, thereby reducing the risk of damage. – Multiphase CO2 transport provides greater flexibility and can be more cost-effective, especially when injecting into low-pressure reservoirs. It opens the door to solutions that today are not commercially attractive, explains Brigadeau at SLB.

Technical Challenges That Must Be Solved

Even though the benefits are clear, multiphase CO2 transport is technically demanding.

CO2 behaves differently from oil and gas. When CO2 mixes with impurities, complex thermodynamic conditions arise which require highly accurate models. Challenges are also linked to rapid pressure releases, where thermal and thermodynamic equilibrium is not reached.

Another critical issue is the precise prediction of flow regimes. Errors here may cause significant deviations in the calculation of pressure drops and liquid accumulation. This, in turn, can lead to incorrect pipeline sizing or flawed operational strategies. – We must be able to predict pressure drops and liquid accumulation with high accuracy. Small errors can have major consequences in both design and operation, Brigadeau continues.

Anchored in Experimental Data

A key strength of the Olga project is its solid foundation in experimental data from multiple laboratories. – Verification against real measurement data is essential. Olga users must be able to fully trust the results when making investment decisions, Hoyer says. He emphasizes that this is not only a question of technical quality, but also of building confidence in an industry facing major investments in CCS.

Industrial and Commercial Significance

For large-scale CCS projects, precise simulations can be decisive for profitability. A more robust tool reduces risk of operational disruptions, leaks, or other unwanted incidents. At the same time, accurate calculations can contribute to optimal sizing of pipelines and process equipment, lowering both capital and operating costs.

As more countries and companies commit to reducing CO2 emissions, the need for reliable simulation tools is growing. Olga is positioning itself as a key contributor to meeting this need, both technologically and commercially. – This is not just a technology investment, but an investment in the ability to realize more CCS projects in a safe and cost-effective way, Hoyer continues.

The Road Ahead

The project is scheduled to conclude in 2025. Already, discussions are underway about an extension to address new needs that may arise as the industry begins to implement multiphase CO2 transport on a larger scale. – We see this as a journey. CO2 management technology will develop rapidly over the next decade. Olga will remain at the forefront, concludes Norbert Hoyer at SLB.

Do you want to learn more about the areas of corrosion, measurement, and monitoring? Check out these articles:

“CO2 Safe & Sour”; How pure must CO2 be for CCS?

Aiming to Make CO2 Calculations More Accurate and Accessible

Government Action on CO₂ Infrastructure Reduces Risk and Cost

Industry wants to cut greenhouse gas emissions through CCS, but lacks clarity on how CO2 transport and storage will be organized.

SINTEF recommends developing a national plan to provide direction and certainty for industrial actors in their future planning.

Who Will Take the Next Step?

Ragnhild Skagestad, Project Manager for Process Technology at SINTEF Industry, has led a concept study on CO2 infrastructure together with Kristin Jordal from SINTEF Energy. In their dialogues with industry, authorities, and technology communities, a common message has emerged: many actors have promising initiatives, but are uncertain about national developments. Without a shared direction, it is difficult to know where investments should be placed and how to ensure flexibility for future users. The project concludes that a comprehensive national plan is needed to outline how CO2 infrastructure can be built out in Norway – and that this responsibility must rest with the authorities.

Need for Coordination

According to Skagestad, we are already seeing a trend where projects are being developed on a first-come, first-served basis and tailored to the needs of individual actors. While this may work in the short term, it increases the risk that the resulting infrastructure will not be cost-efficient or accessible to others in the future.

Skagestad emphasizes that there are many possible approaches to building CO2 infrastructure. What matters most, however, is having an overarching understanding of how the different parts connect. Without this, there is a risk of technical challenges, high costs, and, in the worst case, some emission sources will be excluded.

SINTEF believes infrastructure must be viewed holistically – similar to the transport sector. Core infrastructure for captured CO2 should be planned and facilitated at the national level, so that individual companies can connect as needed.

High Engagement, Low Willingness to Pay

As part of the concept study, SINTEF arranged workshops and meetings with industrial clusters, transporters, authorities, and advisors. While many stakeholders are eager to contribute knowledge and input, few are willing to fund overarching planning efforts. Skagestad stresses that this is not due to a lack of interest. Rather, it stems from uncertainty about which actors will own, build, and operate the infrastructure. Many are happy to join reference groups and participate in processes, but expect the government to take the lead in planning.

Geographical Challenges

Uncertainty also arises from the question of where CO2 will be stored, and how it will be transported. This is especially true for actors located far from current solutions. – The Northern Lights terminal in Øygarden likely won’t be able to meet all future needs. For emission sources in Northern Norway or Eastern Norway, it’s unclear what kind of storage options will be available – or whether they will be able to connect at all without new pipelines or terminals, says Skagestad. She acknowledges several promising regional initiatives, but notes that a coordinated national assessment of technical and economic feasibility is still lacking.

Diverse Industries, Diverse Needs

Developing CO2 infrastructure brings together a wide range of industries. While Skagestad sees this as a strength, it can also lead to disagreements on what constitutes acceptable risk, and which standards should apply. Ernst Petter Axelsen from Gassnova, who serves as CLIMIT’s advisor for this SINTEF project, highlights the divide. – The oil and gas sector has long experience with safety-critical infrastructure and tends to apply strict and costly standards to CCS. For land-based industries, this can be challenging. Many smaller players have limited emissions volumes and tight financial margins; they need flexible and accessible solutions.

In December 2024, Gassnova published an article on the potential for cost reductions across the CCS value chain.

Proposal: Public Review

– One suggestion is that the state launches a Norwegian Official Report (NOU) on national CO2 infrastructure, says Skagestad. Such a process could provide scientific grounding and gather input from across the country. She believes the study should explore where infrastructure should be located, how different actors can connect, and what costs and benefits follow from various models. Skagestad stresses that this should not become a rigid master plan, but rather a flexible framework to guide further development. Goal is to reduce uncertainty and enable broader participation in CCS development.

Greater Predictability, Lower Risk

Skagestad hopes SINTEF’s report will spark discussion on how Norway can best develop a national CO2 infrastructure. She argues that a well-crafted government plan would provide the predictability needed to avoid costly missteps. The goal is not micromanagement, but rather to make it easier for industry to plan and adopt solutions that deliver both emission cuts and economic sustainability.

In April 2024, Gassnova reported on preparations for this concept study, which has received NOK 200,000 in support from CLIMIT.

More Affordable Monitoring of Offshore CO₂ Storage

A collaboration between SINTEF and the French company Geniwind, could enable more cost-effective and flexible monitoring of offshore CO2 storage.

The project began when Pierre Cerasi, Senior Research Scientist at SINTEF Industry, met Geniwind at a conference in Bergen. With a background in offshore wind, Geniwind presented an autonomous seabed monitoring concept. – I thought this could be used for monitoring offshore CO2 storage sites in a much more affordable way than today’s seismic campaigns, Cerasi says.

Moderate Budgets

The collaboration led to an idea development project supported by CLIMIT Demo. Total budget was NOK 300,000, half of which was covered by CLIMIT. SINTEF financed the rest with internal funds. This preliminary phase was completed March 2025.

How to Monitor CO2 Storage for “Eternity”?

CO2 storage in the subsurface requires long-term monitoring to ensure the gas remains where it is intended. But who covers the cost of monitoring over decades or centuries? Pierre Cerasi emphasizes that new solutions must be both cost-effective and operationally practical. – If we can install monitoring equipment deep below the seabed, we reduce noise from all ocean activity and complications from sound wave reflections off the seabed. By staying below 100 meters depth, we avoid much of the noise and can install equipment using simple mechanical drilling, he explains.

The Solution Proposed by SINTEF and Geniwind Includes:

- Shallow wells that can be hammered into the seabed, eliminating the need for drilling rigs. These are equipped with fiber optics and sensors measuring pressure, temperature, and deformation

- Autonomous underwater vehicles that retrieve data from the wells and seabed nodes

- Minimal installation – no need for complex or expensive offshore operations

Costs Must Come Down

A crucial part of the development has been identifying the right depth – deep enough to yield reliable data, but shallow enough to keep costs low. Fiber-optic cables provide high resolution and multiple measurement points. They also offer flexibility for future maintenance.

– This project has, among other things, evaluated experiences from Shell’s Quest project in Canada, which uses highly advanced technology. Pierre Cerasi and his colleagues conclude that most measurements could have been carried out with simpler and cheaper methods. This is highly valuable insight because costs throughout the chain must come down for CCS to succeed globally, says Ernst Petter Axelsen, Gassnova’s representative in CLIMIT and advisor to the SINTEF and Geniwind project.

What Is Already Available on the Market?

Project mapping showed that a wide range of sensors already exists – including for chemical parameters, pressure, and seismic activity. They can withstand pressure and temperature in wells down to 100 meters. This makes it possible to assemble a monitoring system without having to develop all technologies from scratch. The goal is a system that is easy to install, simple to maintain – and cheap enough to be deployed at scale.

Cross-Border Collaboration

The next step is to expand into a larger international project. SINTEF is included in the main French application, but the company must apply separately in Norway. Support from bilateral programs between Norway and France is also under consideration. SINTEF has solid experience with such cooperation, for example the CLIMIT-Demo project SNOWPACCS, with the Swiss Swisstopo a few years ago.

Towards a New Standard for Monitoring?

By combining autonomous drones, fiber optics, and strategically placed sensors, SINTEF and Geniwind are pointing toward a new generation of monitoring systems for CO2 storage. Not only can this reduce costs, but it could also make it practically feasible to monitor storage sites for centuries.

“-We are starting to identify how little is actually needed for effective monitoring. That opens up entirely new possibilities.”

Senior Reearsch Scientist Pierre Cerasi, SINTEF IndustryAiming to Make CO₂ Calculations More Accurate and Accessible

The company ThermoPhys, founded by researchers from SINTEF and NTNU, is developing digital tools for accurate and user-friendly safety assessments in CO2 management.

ThermoPhys was established in 2024, and its first pilot project was completed

in February 2025. The company currently has three employees and plans to expand. The team includes experts with more than a decade of research experience from SINTEF.

The goal is to fill a critical gap in the CCS value chain and make computational tools more comprehensible. With support from CLIMIT-Demo, ThermoPhys launched a pilot project to map industry needs and potential solutions. The company now plans a larger CLIMIT Demo application in collaboration with both commercial software providers and end users.

From Frustration to Solution

– We were frustrated that decades of research on CO2 and hydrogen were scattered and inaccessible to the industry, says Øivind Wilhelmsen, one of the founders of ThermoPhys. He explains that while advanced computational codes developed at SINTEF and NTNU are publicly available on GitHub, they lack user interfaces or support for the people who actually need them. ThermoPhys was founded to make this knowledge available through user-friendly software. The objective is to improve safety and reduce costs throughout the CO2 capture, transport, and storage value chain.

– In CCS, it’s not enough to know that CO2 can be stored, you must also understand how the mixture behaves under different conditions. Will it form acid? Dry ice? Hydrates? These are questions the industry is asking, and we believe ThermoPhys can help answer them, says Ernst Petter Axelsen. As Gassnova’s representative in CLIMIT, Axelsen is advisor to ThermoPhys on the project.

From Open Source Code to Commercial Interface

ThermoPhys builds on open-source research code, packaging it into a visual and user-friendly interface. – You shouldn’t have to be a domain expert to understand what’s happening inside your pipelines. But the model still has to be scientifically grounded and based on the best available data, says Wilhelmsen.

The aim is to make it easier for both operators and financial stakeholders to make well-informed decisions, based on accurate and validated calculation methods.

Collaboration with Oliasoft and a Dedicated Cloud Platform

ThermoPhys is currently advancing on two fronts. In addition to developing its own software, the company is working with others who aim to offer digital CCS tools. In collaboration with Oliasoft, ThermoPhys will integrate its models into software for well injection.

“CO2 isn’t just captured, it must be injected underground. This requires highly accurate input data on the properties of CO2 mixtures with impurities. CCS is complex, and the risks are real if you don’t have control over the mixture properties. We want to make it easy to get it right the first time”

Øivind Wilhelmsen at ThermoPhys AS20 years of strong CCS technology development

Technologies developed through the CLIMIT programme will build up under the Norwegian government’s strategies and work regarding carbon capture and storage (CCS) as a climate initiative, both for achieving national climate goals and so that the technology can be rolled out internationally.

Since 2005, the CLIMIT Programme have seen a major development in the programme’s mandate.

Design of the programme

CLIMIT’s priorities are laid out in a separate programme plan, which defines the types of projects that can be supported. The programme plan is revised every three to four years. These revisions have been necessary to follow trends in technology development within the framework and mandate of the programme. As such, the CLIMIT programme has moved from just supporting projects related to CCS at gas-fired power plants to now including technologies for both the energy and industrial sectors. A key condition for the programme is the requirement for long-term carbon storage for CCS to be viewed as a viable climate initiative.

Research, development and demonstration

The cooperation between Gassnova and the Research Council of Norway has been incredibly fruitful, not least because the programme has a joint secretariat.

CLIMIT R&D is the research arm of the programme, managed by the Research Council of Norway. It focuses on basic research and development of new knowledge and technologies for CCS.

CLIMIT Demo is the demonstration arm, managed by Gassnova. It supports the development, piloting and demonstration of technologies at larger scale to reduce risks and costs. Several projects have progressed from R&D to Demo. It is the dialogue and understanding in the secretariat which is important for getting this to work for applicants.

What is going on around us?

The expansion of carbon capture and storage as a method to combat climate change has been slow due to a weak market for these solutions. A significant barrier has been the absence of robust business models that offer investors the predictability and earning potential needed to commit to CCS projects.

Interest in and the relevance of CCS is well documented, but the current market weakness has resulted in a weak ability to pay and justified scepticism from private stakeholders interested in building fullscale facilities to capture carbon.

However, the CLIMIT programme has been able to make a difference here. The best example is the Longship project, where previous CLIMIT projects have been vital for Norway now being able to realise large-scale carbon capture and storage. Another example is the cluster projects. CLIMIT has contributed to industrial actors cooperating on common CCS infrastructure. In other words, CLIMIT is vital to the work on reducing industrial greenhouse gas emissions.

.

Technology trends and future opportunities

When CCS projects need to be realised – such as when Longship moves into its operational phase, for example – experience from the operational phase will offer major learning opportunities that will provide a basis for improvements of technologies and solutions that are already mature. These learning opportunities will contribute to the further development of well-functioning technologies towards a standardisation that will reduce costs and risks.

It is reasonable to expect that interest in wholly new solutions based on CCS will grow in the years ahead and will be of significance for which development projects will be picked up by Norwegian industry. The production of hydrogen from natural gas with CCS, direct air capture or in combination with the use of biomass, use of carbon capture and utilisation (CCU) and international cooperation projects are relevant examples in this context. CLIMIT will also be important for promoting such technologies.

Collaboration and networking

CLIMIT promote collaboration between industry, academia and international partners. This is crucial for strengthening the dissemination of knowledge and ensuring relevance for industrial use both in Norway and internationally.

Communication and dissemination

It is important that CLIMIT-supported projects contribute to the dissemination of information to provide the public and decision makers with sufficient knowledge about CCS as a necessary climate initiative. Projects are encouraged to also include public information campaigns via social media, discussion fora and other public spaces.

We look forward to our continued cooperation with those receiving CLIMIT support.

Clean Hydrogen with Hybrid CO₂ Capture

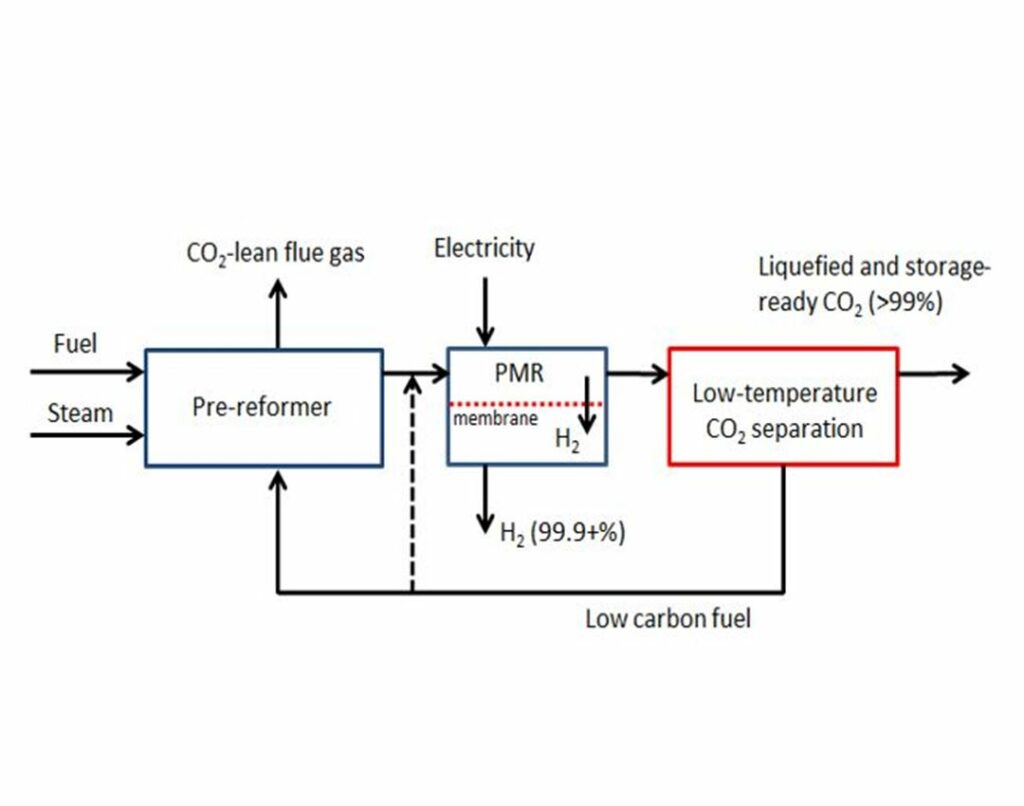

The MACH-2 project has developed a hybrid process for hydrogen production from natural gas, achieving high efficiency and a high CO2 capture rate.

Combination of membrane technology and liquefaction results in excellent energy efficiency and high purity of the end products. The project MACH-2 was a collaboration between SINTEF Industry, SINTEF Energy, and NTNU. CLIMIT supported the project with NOK 7.5 million.

A Key Energy Carrier

Hydrogen is a crucial energy carrier in the transition to a low-emission society. To reduce greenhouse gas emissions associated with hydrogen production from natural gas, CO2 must be effectively captured and managed. The MACH-2 project, which ran from 2019 to 2024, developed a novel process that integrates two established capture technologies.

– Our approach was to combine hydrogen production using Protonic Membrane Reformer (PMR) technology with low-temperature CO2 capture via liquefaction in a new, integrated process – where both technologies operate within their optimal performance ranges, says Thijs Peters, Project Manager at SINTEF Industry.

CO2 Purity and Calorific Value

The membrane technology uses ceramic materials to produce hydrogen from natural gas, which is reformed directly on the membranes. The process is powered by electricity and internal heat generated during hydrogen separation through the membrane. The retentate gas, what does not pass through the membrane, contains CO2, water vapor and residual hydrogen.

– Membranes are excellent for extracting hydrogen, but there is a limit to how much can be recovered before efficiency declines. Therefore, we allow a portion to remain and capture CO2 in the subsequent stage, Peters explains. The retentate is then processed in a separate unit, where CO2 is liquefied through cooling and pressurization.

“This allows for high CO2 purity while recovering the remaining valuable molecules in the retentate, which can either be recycled back into the membrane process, or used as an energy source within the system. At the system level, the proposed concept separates approximately 99 % of both H2 and CO2, even when the membrane operates at relatively low hydrogen recovery rates. This results in energy-efficient H2 production with low carbon intensity”

Thijs Peters, project Manager at SINTEF Industry

Model Validation

Several experiments were conducted during the project period. Membrane stability was tested for up to 1800 hours, including variations in gas composition and hydrogen withdrawal. Liquefaction experiments were performed using gas mixtures containing hydrogen, methane and carbon monoxide. To accommodate these experiments, the Cold Carbon Capture Pilot rig in Trondheim was upgraded. The tests demonstrated that CO2 could be separated at up to 99.9 % purity, under pressures between 40 and 70 bar and temperatures as low as -55 °C. – We compared the results with simulation models. The models aligned well with the experiments, which gives us confidence in relying on simulations for designing future systems, says the SINTEF Industry project manager.

Low Energy Loss and High Capture Rate

Through simulation and optimization, MACH-2 developed a process flow model for the entire system. It demonstrates that an integrated process provides higher energy efficiency and lower CO2 emissions, compared to more conventional hydrogen production methods with CO2 capture. This indicates that the concept is economically competitive.

Ready for Next Phase

Results are now being carried forward in new projects, including a planned demonstration facility with a hydrogen production capacity of 50 kg per day. The technology is also being applied in European projects where membranes are used for biogas capture.

“Many are working on membranes and liquefaction separately. We have demonstrated how they can be connected into one holistic process. This opens up new opportunities for hydrogen production from both natural gas and bio-based sources, with integrated CO2 capture.”

Thijs Peters of SINTEF Industry.Carbon Management; Project Aims to Transform CO₂ Adsorption Technology

The mission, jointly led by SINTEF and TotalEnergies, is focused on developing next-generation CO2 adsorption technology, which could significantly outperform today’s state-of-the-art solvent-based absorption systems.

The “Disruptive CO2 Capture” (CO2 Adsorption Technology) project has total budget of NOK 24 million, of which 50 % is financed by CLIMIT.

While CO2 capture using solvents is currently the dominant method, it remains expensive and energy intensive. Adsorption, where CO2 is captured by solid materials called sorbents, offers a promising alternative. The goal is clear; reduce both capital expenditure (CAPEX) and operating costs (OPEX), by at least 20 % compared to current leading absorption systems.

– We’re trying to find the best material-process combination. Ambition is to optimize both the sorbent material and the process design to reduce costs and improve efficiency, says Dr Shreenath Krishnamurthy, Senior researcher and Project Manager at SINTEF.

Why Adsorption?

Unlike solvent-based absorption systems, which rely on chemicals to bind CO2, adsorption uses solid materials to capture CO2 molecules directly from flue gases. Potential advantages are many; lower energy requirements, better atmospheric emission profiles, and possibly more compact plant designs. Adsorption is not yet mature for point source CO2 capture, with many technical hurdles to overcome.

“There are thousands of potential sorbents out there, from traditional to newly engineered materials. But which material works best with which process in terms of cost efficiency? That’s the question we’re trying to answer.”

Dr Samuel Heng, R&D Project Manager at TotalEnergiesA Theoretical Backbone

At the heart of the project is a sophisticated simulation model designed to test different combinations of materials and processes. DCC3 aims to evaluate temperature swing adsorption processes for NGCC flue gas. The team is building a flexible mathematical framework and cost framework which can simulate a range of adsorption processes from fixed beds, rotary beds, fluidized bed and moving bed processes, by switching specific parameters on and off. These simulations are grounded in gas-phase thermodynamics, adsorption kinetics, and equilibrium data.

The model will help the team optimize each process and adsorbent for performance and cost, validate key parameters, and ultimately select the most promising adsorbent and process configuration for future pilot testing.

– It’s not just about the best material; it’s also about finding the right process design. We’re doing a lot of simulation work to forecast CAPEX and OPEX, and we’re collecting and feeding experimental data to refine our models, Dr Shreenath Krishnamurthy continues.

Overcoming Data Gaps

One of the key challenges is the lack of publicly available data, especially concerning how sorbents interact with water vapor in flue gases. This has required new experiments and delayed some parts of the project. – In many cases, we don’t have the data we need from literature, so we’re measuring some properties ourselves, and also testing hypothetical ideal sorbents to understand the performance gap and identify research objectives to decrease carbon capture cost, says Dr Heng

The lack of data hasn’t stopped progress, but it has shaped the project’s direction. By exploring both existing and hypothetical materials, the team can map out what an ideal system would look like, and what would need to improve in current technologies to get there.

Broader Implications

Although this project focuses on post-combustion capture from natural gas combined cycle (NGCC) plants, its outcomes could influence other CO2 capture applications, including direct air capture.

The collaboration has already sparked two additional joint projects between SINTEF and TotalEnergies, focusing on carbon capture. The projects coordinated by SINTEF are funded by the clean energy transition partnership (CETP) and TotalEnergies plays an active role in the project.

One technical objective which stands out is minimizing the physical footprint of future carbon capture units. If adsorption technology can achieve both cost and space efficiency, it could make retrofitting existing plants, especially in space-constrained brownfield sites, much more feasible. – In greenfield cases, we have more flexibility. In brownfield projects, integration is very complex. This is why we need compact, efficient solutions, says Dr Heng at TotalEnergies.

Looking Ahead

The project aims to reach Technology Readiness Level (TRL) 4 within four years. By the end, partners will conduct a thorough comparison between the newly developed adsorption technology, and current solvent-based systems. This will form the basis for a “go/no-go” decision regarding future development.If successful, the project could pave the way for design of a pilot unit, taking a major step toward commercial implementation.

“Today, carbon capture is technically feasible but still expensive to make economic sense. This project is about finding a way to change this. In an era of tightening climate targets and uncertain carbon pricing policies, innovations like these are vital. As policy and technology evolve, projects like this could shape the future of industrial decarbonization across Europe and beyond.”

Ernst Petter Axelsen, Gassnova representative at CLIMITAdvancing Carbon Management Through Global Collaboration

The CLIMIT Summit 2025, held at Bølgen Kulturhus in Larvik (Norway), marked the 20th anniversary of the CLIMIT program, bringing together leading experts, industry stakeholders, and researchers to discuss the future of CO2 management technologies.

Discussions centred on key advancements in carbon capture, utilization, and storage, as well as the role of innovation and international collaboration in scaling these technologies.

Since 2005

Since its inception in 2005, CLIMIT has been instrumental in developing Norwegian and international solutions for CO2 management. The program, a collaboration between Gassnova and the Research Council of Norway, has supported more than 800 projects focusing on research, development, and the demonstration of CCS technologies. With a strong emphasis on knowledge-sharing, this year’s summit continued to serve as a platform for industry leaders and policymakers to exchange insights on advancing carbon management solutions.

(Northern Lights)

(Heidelberg Materials Cement Norway)

Sleire Lundby

(Hafslund Celsio)

Update on Longship

During the first sessions, representatives from Northern Lights, Brevik CCS, and Hafslund Celsio provided updates on Norway’s ongoing CCS projects. Northern Lights has reached full operational capacity, including CO2 transport ships and a dedicated storage terminal, paving the way for commercial-scale carbon storage. Brevik CCS is nearing completion, preparing to capture emissions from cement production, while Hafslund Celsio has secured its final investment decision for its waste-to-energy CCS plant in Oslo, scheduled to be operational by 2029. These projects exemplify Norway’s leadership in demonstrating how CCS can reduce industrial emissions while fostering economic growth.

The Longship project remains central to this effort, serving as a blueprint for global CCS deployment by proving the feasibility of large-scale carbon management.

Europe’s climate strategy

A major highlight of the summit was the European Commission’s perspective on CCS as a cornerstone of Europe’s climate strategy. Rosalinde van der Vlies introduced the EU’s “Competitiveness Compass,” a roadmap aimed at securing economic growth while achieving climate neutrality. She emphasized the need for robust investments in CCS infrastructure to meet the EU’s target of storing 50 million tonnes of CO2 annually, by 2030. The role of CCS in industrial decarbonization and clean tech competitiveness was a key takeaway, with the Commission reaffirming its commitment to supporting the development and deployment of these technologies through policy frameworks and funding initiatives.

UK and USA

Charlotte Powell from the UK Department for Energy Security and Net Zero highlighted Britain’s substantial investment in CCS, amounting to £21.7 billion over 25 years. The UK government is focusing on the development of regional CCS clusters, particularly the East Coast Cluster, set to begin construction in 2025. Powell underscored the strategic importance of leveraging the North Sea’s storage potential and strengthening collaborations with Norway. The UK’s investment in CCS reflects a broader global trend of integrating carbon capture into national net-zero strategies.

The U.S. Department of Energy’s Mark Ackiewicz provided insights into America’s accelerating carbon management efforts. With 19 operational facilities and over 200 CCS projects in development, the U.S. is rapidly expanding its carbon capture, transport, and storage capabilities. Ackiewicz highlighted the importance of international partnerships, particularly with Norway, in advancing CCS technology. He also emphasized the role of U.S. national laboratories in driving innovation in hydrogen production, CO2 removal, and industrial decarbonization, reinforcing the importance of research and development in achieving long-term climate goals.

Strategic priorities

The discussions also looked ahead to the future of CCS, with Trond Moengen, Chair of Gassnova, and Eva Falleth from the Research Council of Norway, outlining strategic priorities leading up to 2030. Moengen underscored 2025 as a pivotal year for CCS, as the Longship project reaches full operational capacity, demonstrating an integrated CO2 value chain. He emphasized the importance of continuous research, operational improvements, and cost reduction strategies to make CCS more economically viable. Falleth echoed this sentiment, stressing the crucial role of industry-academia collaboration in driving innovation. The seamless cooperation between Gassnova and the Research Council of Norway was highlighted as a key factor in Norway’s CCS advancements, ensuring that CLIMIT remains a cornerstone of future research and development initiatives.

AI and Carbon Management

The final day of the summit brought attention to the role of Artificial Intelligence in accelerating CCS deployment. Julio Friedmann emphasized how AI can optimize key aspects of carbon management, including CO2 transportation, storage site selection, and permitting processes.

AI-driven solutions have the potential to reduce costs, improve efficiency, and streamline regulatory compliance. Friedmann highlighted AI’s potential in material discovery, digital twinning for retrofitting existing facilities, and enhancing decision-making for CO2 storage sites. However, he stressed the need for better data access and cross-sector collaboration to fully harness AI’s capabilities in the energy sector.

Juho Lipponen from Mission Innovation called for a rapid scale-up of carbon management technologies to gigaton levels by 2030. He underscored the role of international initiatives like the Clean Energy Ministerial (CEM) and Mission Innovation (MI) in fostering global cooperation, policy development, and investment in CCUS and carbon dioxide removal (CDR). Lipponen emphasized the need for stronger partnerships between governments, industries, and research institutions to accelerate the deployment of scalable carbon management solutions. The importance of data sharing and financing mechanisms was highlighted as critical enablers for achieving commercial viability in CCS projects.

CCS Status Worldwide

Jarad Daniels from the Global CCS Institute provided an overview of the current state of CCS deployment worldwide. With 50 operational projects capturing approximately 50 million tonnes of CO2 annually and an additional 44 projects under construction, CCS is expanding at an unprecedented rate. Daniels highlighted the need for continued policy support, financial incentives, and strategic industry collaborations to ensure CCS scales in line with global climate targets. The Global CCS Institute remains committed to providing expertise and data to accelerate the adoption of carbon management technologies across diverse sectors and regions.

CLIMIT´s crucial role ahead

As the summit concluded, the overarching message was clear; CCS is a critical tool in the fight against climate change, and Norway remains at the forefront of this technological revolution. The CLIMIT program has played a crucial role in bridging the gap between research and industrial applications, positioning Norway as a global leader in CO2 management. As Longship transitions into full-scale operation and CCS technology continues to evolve, the insights gained from this year’s summit will shape the next phase of carbon management, ensuring that CCS remains a viable and scalable solution for reducing global emissions.

The next CLIMIT Summit will be held in 2027.