04.06.2024

Low-Pressure CO₂; Greater Transport Volumes and Increased Capacity

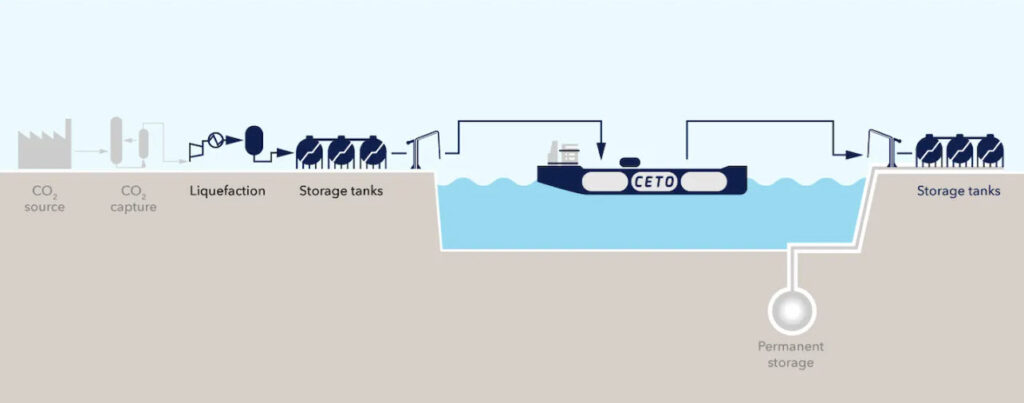

To accommodate the foreseen increase demand for transportation of CO2 for CCS purposes, a development towards larger ships and transported volumes is expected.

A low-pressure transport system is an alternative to medium pressure and is the preferred solution for most of the projects accommodating cargo volumes larger than 20 000 m3.

Transport Conditions

At low-pressure conditions, the liquid CO2 is transported at pressure and temperature closer to the triple point compared to today’s industry practice. The reduced pressure and temperature allow for larger cargo tank diameter, and also benefits from increased liquid product mass density – leading to larger cargo capacity per ship, while reducing the overall shipping cost.

CETO Project Development

The project “CO2 Efficient Transport via Ocean” (CETO) managed by DNV is a partnership between Equinor Energy AS, Gassco, TotalEnergies, EP Norge AS, and Shell Global Solutions International B.V. CLIMIT supported the CETO project with over 8.2 million NOK, which is 32% of their total budget.

Transport; Project Purpose

– CO2 transport by ship has been performed for several decades – but on a limited scale for businesses in the food, cleaning, and chemical industries. Currently, there is no operational experience with low-pressure ship transport of CO2, which is therefore associated with a higher risk compared to the medium-pressure alternative. Such risks are minimized with proper design of the processes in the transport chain – says Ernst Petter Axelsen at Gassnova.

CETO investigates the fundamental aspects of a low-pressure value chain – and aims at reducing the uncertainties related to design, construction, and operation as well as enhancing solutions for ship transport of CO2.

Project Phases

The project was divided into a Planning Phase and an Execution Phase.

The goal of the Planning Phase (Q2 to Q4 2020) was to identify novel elements, associated technical uncertainties and to establish relevant qualification activities, necessary to address these risks and the uncertainties.

The qualification activities were carried out in the Execution Phase (Q3 2021 to Q1 2024) and encompassed:

- Conceptual design of an onshore conditioning and liquefaction plant, and experimental demonstration of liquefaction at low pressure (in synergy with SINTEF industry)

- Development of a suitable conceptual ship design and cargo handling system for transporting 30,000 m³ CO2

- Design of the cargo containment system and qualification of a selected material to accommodate the large cargo weight, ensure constructability and operation at design temperature

- Design, construction and commissioning of a test rig resembling a ship-to-terminal cargo handling system – to investigate, via experimental activities, the operability of a low-pressure system, and determine a safe envelope for the operations

- Benchmarking and validation of simulation tools for assessing cargo handling operations in the low-pressure domain.

- Experimental and modelling activities within CO2 thermodynamics to reduce uncertainty in digital design tools.

Project Results So Far

– The results of the Qualification Activities indicate no technical obstacles to the deployment of low-pressure CO2 ship transport value chain. Though there are technical elements that require further attention during project specific development. More specifically, CETO has demonstrated the feasibility of a low-pressure liquefaction plant by developing a conceptual design that meets the design specifications. The conceptual design of the ship, cargo tank, and cargo handling system shows that a dedicated 30K low-pressure LCO2 carrier can be developed, in compliance with the current rules and regulations – says Gabriele Notaro, project manager at DNV.

The testing campaign on the medium-scale pilot rig demonstrated that the cargo handling operations could be carried out without dry ice formation, at vapor pressure in the range of 6 to 9 barg. Lastly, the accuracy and suitability of design process simulation tools were benchmarked with good agreement against experimental tests. These activities provided valuable experience and understanding of the fundamentals of a low-pressure value chain,

and the results indicate that low-pressure is technically feasible.

CLIMIT’s Contribution

– CLIMIT has been an essential facilitator, providing valuable guidance on handling the project through different phases. Despite technical challenges and elements requiring continuous industry focus, the project partners will use the results and knowledge in internal decision-making processes and specific CCS infrastructure activities – concludes Gabriele Notaro at DNV.

Future Plans

CETO partners are discussing further activities related to operations under low-pressure conditions, including:

- Investigate alternative materials suitable for use at low temperatures, addressing production and welding technology and to identify a cost-effective solution for the relevant temperature ranges

- Evaluation of the feasibility, benefits, and technical barriers of using re-liquefaction on low-pressure CO2 ships to control boil-off during transport, thus reducing the necessary design pressure margins for cargo tanks

- Investigation of solutions for different impurities, including acid produced by chemical reactions under low-pressure conditions

- Examination of chemical reactions between impurities under low-pressure conditions and possible corrosion effect

- Determination of a representative CO2 product specification for the low-pressure option, which may involve analysing the balance between lowering impurity levels and reducing corrosivity.

Publications Following the CETO Project

To date, the following publications have been released based on the project’s work:

- Gabriele Notaro, Jed Belgaroui, Knut Maråk, Roe Tverrå, Steve Burthom, Erik Mathias Sørhaug “CETO: Technology Qualification of Low-Pressure CO2 Ship Transport” 16th Greenhouse Gas Control Technologies Conference, Lyon 23-27 October 2022

- Michael Drescher, Adil Fahmi, Didier Jamois, Christophe Proust, Esteban Marques-Riquelme, Jed Belgaroui, Leyla Teberikler, Alexandre Laruelle. “Blowdown of CO2 vessels at low and medium pressure conditions: Experiments and simulations” 0957-5820/© 2023 Institution of Chemical Engineers. Published by Elsevier Ltd.

- GHGT16 Proceedings, Poster presentation, “BLOWDOWN OF CO2 VESSELS AT LOW AND MEDIUM PRESSURE CONDITIONS: EXPERIMENTS AND SIMULATIONS”; Michael Drescher, Adil Fahmi, Didier Jamois, Christophe Proust, Esteban Marques-Riquelme, Jed Belgaroui, Leyla Teberikler, Alexandre Laruelle. 16th Greenhouse Gas Control Technologies Conference, Lyon 23-27 October 2022

- Rod Burgass, Antonin Chapoy “Dehydration requirements for CO2 and impure CO2 for ship transport,” Fluid Phase Equilibria. Volume 572, September 2023, 113830

- Antonin Chapoy, Pezhman Ahmadi, Rod Burgass “Direct Measurement of Hydrate Equilibrium Temperature in CO2 and CO2 Rich Fluids with Low Water Content,” Fluid Phase Equilibria Volume 581, June 2024, 114063

- Franklin Okoro, Antonin Chapoy, Pezhman Ahmadi, Rod Burgass “Effects of non-condensable CCUS impurities (CH4, O2, Ar and N2) on the saturation properties (bubble points) of CO2-rich binary systems at low temperatures (228.15–273.15 K)” Greenhouse Gases: Science & Technology, 26 December 2023