27.09.2023

CO₂ adsorption: with the potential to save costs and the climate

CO2 adsorption is a promising technology option for capturing CO2. Some of the benefits can be lower energy consumption, a reduced CO2 footprint and fewer expensive investments.

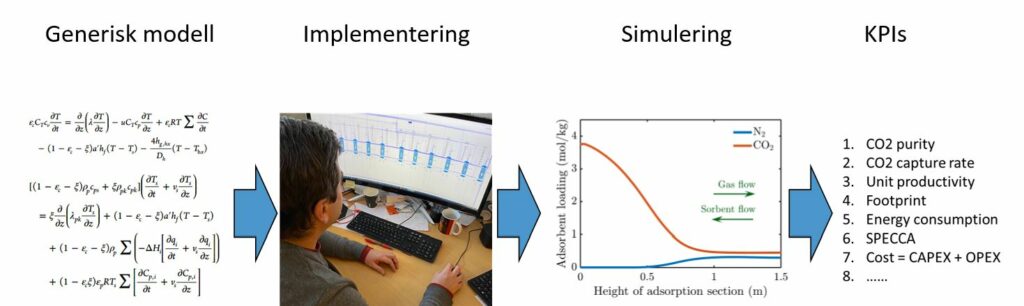

Adsorption technology is in an early phase when it comes to CO2 capture from industry and has technical challenges that must be resolved. Therefore, a project has been initiated under the auspices of SINTEF Industry and TotalEnergies Norway to simulate the processes. The total budget is NOK 24 million, of which CLIMIT supports half.

What is unique about CO2 adsorption?

Adsorption refers to the process where CO2 molecules are attracted and bound to the surface of a solid substance, such as activated carbon or zeolites. This happens when the CO2 molecules interact with the surface atoms or groups on the solid material through weak chemical bonds. The current most common method of CO2 capture is absorption. There, CO2 from flue gas is dissolved in a suitable liquid. This process usually means that the CO2 molecules also react with components in the liquid. The binding energy for CO2 will therefore be higher in the case of absorption than in the case of adsorption. For both adsorption and absorption, energy must be supplied to release the CO2 molecules again.

What has been achieved?

“In the project, we have worked with 6-7 different processes, and we are working to find the most effective combinations with a number of sorbents (more than the number of amines on the market today). We analyze the sorbents and use the experimental data to simulate how effective and good the various processes will be. The hope is to find combinations that will be better than current amine technology. We already see big differences between the processes when it comes to CO2 footprints”, says Richard Blom, SINTEF. He also mentions that there are big differences in the way in which the processes use the energy. “For example, it is significantly more efficient to move the fixed sorbent between cold and hot sections in the process than to have the sorbent fixed in the column and vary the temperature of the entire column, but one of the prerequisites is that the sorbent can withstand being moved”, emphasizes Richard.

It is also challenging for the project as many of the technologies being tested are at very different TRL levels, which makes the simulations extra demanding and setting up coding that gives comparable results. There will also be local conditions that come into play, such as access to solid sorbent. If it is nearby, the cost picture will be different. The aim of the project is to find an adsorbent/process combination that could eventually be suitable for a pilot on an industrial scale.

CO2 adsorption – improve performance

“Before decisions are made about upscaling, the lab pilots at SINTEF Industry will be used to demonstrate the validity of the simulation results obtained, under different operational constraints”, concludes Svein Gunnar Bekken in CLIMIT. Looking forward to getting the results.