30.09.2024

CLIMIT: Acoustic Shockwave Technology for CO₂ Storage

The company qWave is developing a new method for measuring horizontal stresses in the caprock during CO2 storage projects.

This technology has the potential to enhance both the safety and the economics of CO2 storage. The project is supported by CLIMIT with just under NOK 4.8 million. Jan Ove Nesvik, CEO of qWave, is responsible for the project.

Safety and Economics

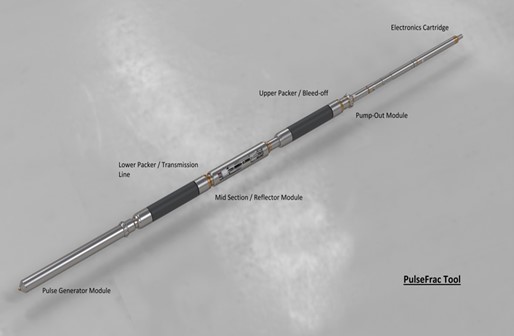

Effective and safe CO2 storage requires a solid understanding of the horizontal stresses in the caprock, which serves as a sealing element to prevent leakage from storage reservoirs. Caprock is a critical component in these projects, preventing CO2 from migrating out of the storage areas. To assess how much CO2 can be injected, it’s crucial to understand the stresses affecting the rocks. A better understanding of the caprock’s properties can help increase CO2 injection volumes per well. By minimizing the risk of leakage, this will reduce storage costs and improve safety.

Current methods for measuring horizontal stresses, such as the Leak-Off Test (LOT) and the use of straddle packers, have several limitations. These methods can produce unreliable results, requiring repeated measurements to ensure accurate data. This becomes especially challenging in deepwater environments, where costs escalate rapidly. The existing solutions are also limited to certain depths and may be inadequate as stress levels in the rock formation can vary with depth. Thus, it is challenging to provide an accurate assessment of storage properties, making projects both costly and complex.

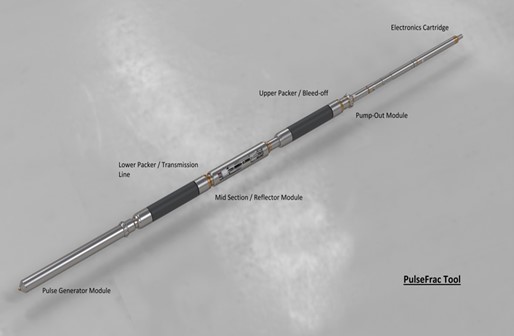

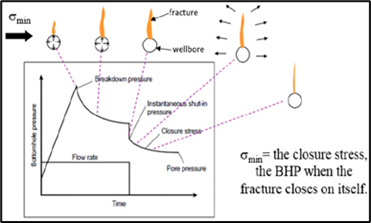

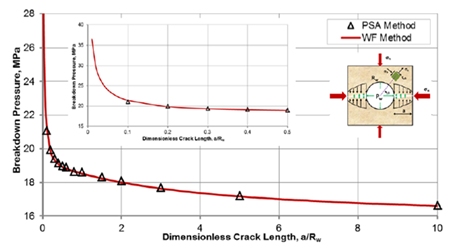

Inspired by Medical Science

qWave has drawn inspiration from medical technology, particularly Extracorporeal Shock Wave Lithotripsy (ESWL), which is used to break kidney stones using acoustic shockwaves without surgical intervention. By transferring the principles from ESWL to well technology, qWave has developed a method using focused shockwaves to create a weak point in the rock formation, enabling more precise measurement of horizontal stresses necessary to assess CO2 storage capacity. The technology includes a shockwave generator with a capacity of up to 30,000 volts. By focusing the shockwaves, qWave is able to create a perforation several centimetres deep in the borehole wall. A custom pump and equipment are used to fracture the formation where the perforation is made, and then gradually close it again until the minimum horizontal stress is measured. This allows qWave to perform better measurements in less time.

The technology has already shown promising results. The prototype has been successfully tested. The shockwave technology was developed in collaboration with Harald Eizenhöfer, former Research Director at Dornier MedTech Systems GmbH, and Hartlauer Präzisions Elektronik GmbH. The first demonstration of the prototype took place in September 2023 at NORCE/Ullrigg in Stavanger, where the tool proved to be both robust and functional under realistic well conditions. A second demonstration in November 2023 confirmed this impression.

Industry Partnership

qWave has established a Joint Industry Project with industry partners including Equinor, Vår Energi, DNO, and OMV. These companies contribute expertise and funding, while also defining technology needs and development goals. The partners see potential in qWave’s technology – not only to improve safety and cost-efficiency in CO2 storage projects, but also for applications in oil and gas drilling.

The next major milestone for qWave and its industry partners is to demonstrate the technology in an offshore well. This is an important step toward commercializing the technology. A successful offshore demonstration will also help build confidence in the technology and open up further market opportunities – both in Norway and internationally. Several more tests and demonstrations are being considered before the technology is demonstrated offshore.

– CLIMIT’s contribution has been crucial for our project. The support for demonstrating the technology has contributed to the development of an advanced prototype, and enabled extensive testing at NORCE’s test center in Stavanger. Such tests are costly but essential, to show that the technology being developed and tested in qLab also operates as expected under well-like conditions. Most importantly, we are learning and acquiring knowledge we didn’t have before, says Jan Ove Nesvik of qWave.

– With a strong commitment to innovation, collaboration, and a focus on meeting industry standards, qWave is positioned to make a significant difference. The further development and commercialization of this technology will be an important step forward for sustainable and safe CO2 storage solutions. Focus on innovation and partnerships could set new standards in the industry, says Kirsten Haaberg, Gassnova’s representative in CLIMIT and advisor to the project.

The Road Ahead

The plan is to develop a commercial 2.0 version of the tool, which will offer even better solutions for measuring horizontal stresses in wells. This could become the standard for both CO2 storage projects and oil and gas drilling. Goal is to improve safety and efficiency, representing a significant advancement in geomechanically analysis.