Gabriele has a background in Naval Architecture and Marine Engineering from the University of Genoa, Italy.

Joined DNV in 2007 and worked as a structural engineer for the Maritime Advisory focusing on the ultimate strength of vessels and offshore structures, rule development, R&D, design verification and trouble shooting. Member of ISSC since 2015, he is currently on the “Renewable Energy” committee.

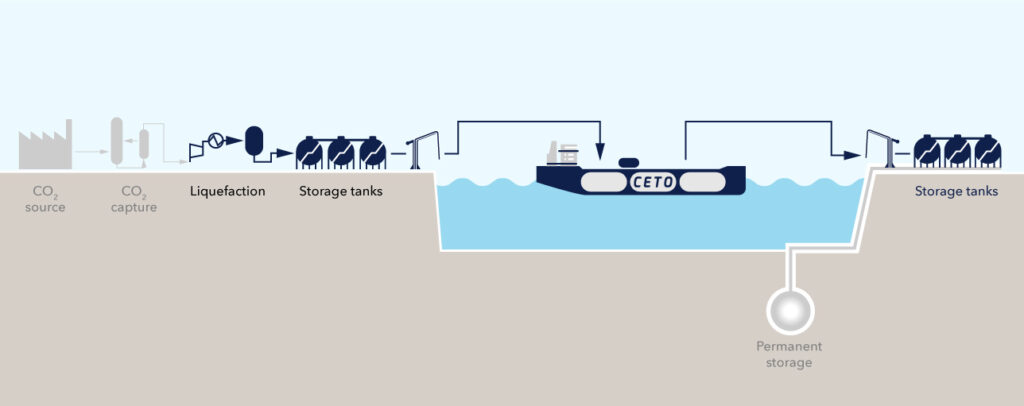

Gabriele contributed to projects within the production, transportation, and storage of liquefied gas and concept development with an increasing focus on CO2 transport by ship in the context of CCS and CCU. At present, he is managing the JIP on technology qualification of low-pressure shipping solutions on the behalf of the DNV.