Safe CO₂ storage using traceable noble gases

The University of Oslo has developed a new and effective method of monitoring CO2 storage sites by measuring the quantity of noble gases in CO2 streams.

When large amounts of CO2 need to be stored safely underground as a climate initiative, we need to be able to document that it stays where it is. It requires technology that measures carbon content along with the possibility for checking where carbon is coming from in a quick, affordable and accurate manner. The University of Oslo has researched a method that can provide an answer quickly and affordably. Noble gases are the key.

A new method of monitoring

During the ICO2P project, project manager Anja Sundal, PhD fellow Ulrich Weber and their team developed a method whereby analysis of noble gases and CO2 can be used to monitor CO2 capture and storage. The chemical and physical “fingerprint” of various isotopes and relative concentrations of gases can be used to identify CO2. Partners in Switzerland have created an instrument that can measure extremely low concentrations of noble gases. Researchers in ICO2P have used this instrument for the entirely new purpose of monitoring CO2.

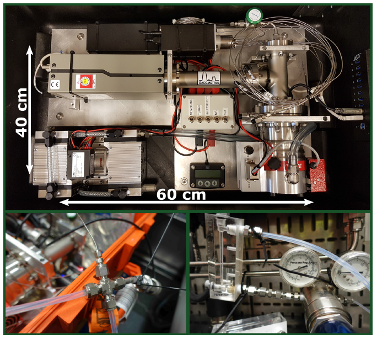

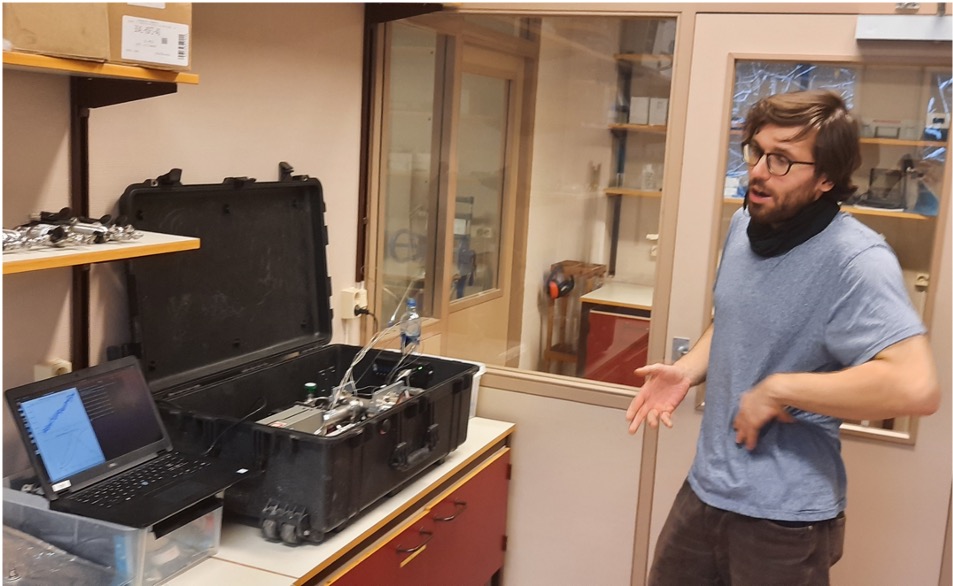

“We have designed a mobile and cost-effective monitoring programme for CO2 capture operations and storage sites on the Norwegian continental shelf. The equipment fits in to a small, portable suitcase and can be easily transported to where we need to take measurements,” says Sundal.

During the ICO2P project, the University of Oslo worked with researchers from Eawag in Switzerland, who developed this device, a mass spectrometer, which is totally unique since it can measure extremely low concentrations of noble gases (He, Ne, Kr, Xe, Ar), as well as other environmentally relevant gases (O2, CH4, CO2 and N2) out in fields. This is a significant development as knowledge of gas compositions can provide a lot of environmentally relevant information right there and then. All origins of CO2, in the atmosphere, the ocean, produced by bacteria, or captured from industrial processes, have their own natural, unique imprint of noble gases.

Samples gathered from natural gas fields

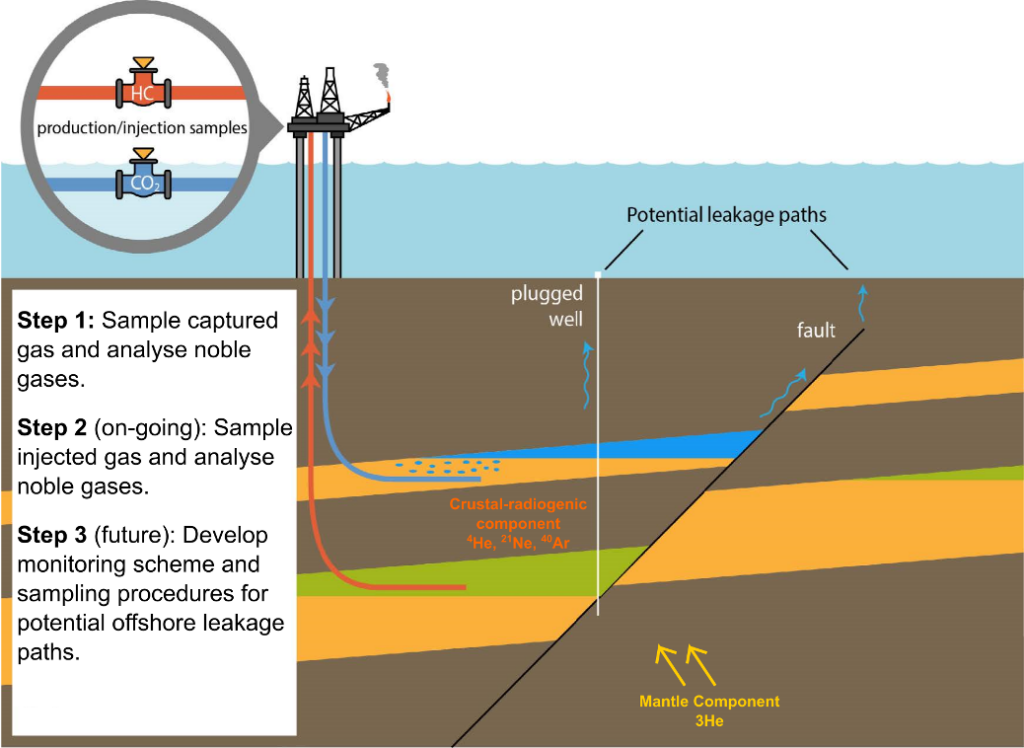

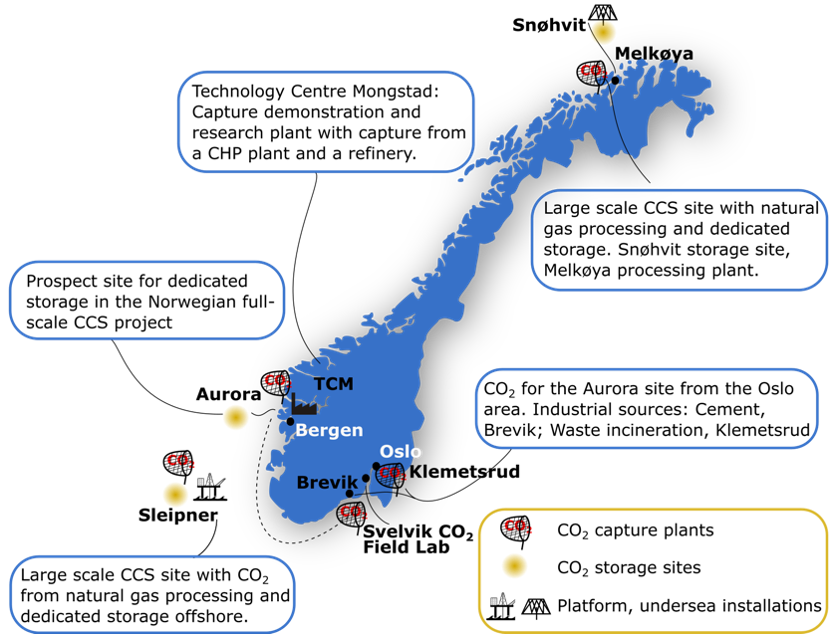

During the project, the ICO2P team gathered samples from Norwegian natural gas fields, CO2 capture plants and at CO2 storage sites in order to gain understanding about the geochemistry and isotope signatures of gases needing to be stored, and to find out if it is possible to identify them later and distinguish them from other gas sources.

“We have monitored noble gas variation in different carbon capture operations using this instrument and adapted calibration methods,” Sundal explains.

Measurements were carried out at the Technology Centre Mongstad (TCM), at Melkøya (Snøhvit) and at the Klemsterud waste incineration plant. This has not previously been surveyed and provides new scientific insight into the processes that causes stored gas to have a unique signature. Noble gas concentrations in “captured” CO2 appear to be much lower than in the atmosphere, while there are significant differences in concentrations and signatures between various capture operations. Time variations have also been documented in the gases’ signatures, something which offers insight into capture processes.

Knowledge about gases’ chemical and physical “fingerprint” can later be used to identify the source. This is vitally important for being able to monitor the CO2 if it should flow out of a storage site, because you need to be able to distinguish between anthropogenic and natural gases that seep out from the seabed.

Noble gas signatures

PhD fellow Ulrich Weber has utilised knowledge about noble gas signatures in captured and anthropogenic CO2 to model how signatures change when injected CO2 comes into contact with fluids (fossil saltwater) in geological reservoirs. Calculations show that with time, the injected gas will change its signature, since it will absorb more noble gases from the reservoir. The signature will nevertheless be recognisable and distinguishable from both atmospheric gas, fossil natural gas, gas produced by bacteria and gas hydrates.

There has been excellent collaboration between academia and industry. Industrial partners have contributed as supervisors, made significant contributions to publications, made data available for the project, and contributed with finances to the project.

The results from the project are useful for industry. The project presents a measurement system that fits in to a small suitcase. This means both researchers and industrial operators can take it with them to where they need to make CO2 and noble gas measurements to verify safe gas storage. A simple, affordable and practical solution.

Key data about the project

Title: ICO2P – Application of noble gas signatures in monitoring schemes for offshore CO2 storage

Project number: 280551

Partners: University of Oslo (project owner), Equinor, Shell, Eawag

Project period: 2018–2021

Budget: NOK 9.2 million, including NOK 5.5 million in funding from CLIMIT

Meeting goals through international cooperation

For the last five years, CLIMIT has built up a strong portfolio of international projects through ACT, Accelerating CCS Technologies. This has led to research that delivers the results needed to construct fullscale CCS facilities.

ACT is a network of 16 countries and regions which work together on calls for project proposals and knowledge sharing. The Research Council of Norway is the coordinator of ACT and Gassnova is also a Norwegian partner.

Achieved good results

ACT was established in 2016 after which it signed a five-year contract with the European Commission. The expiry of the contract at the end of 2021 marked an important milestone for ACT. Strong results were achieved, and new opportunities are being explored to continue ACT.

ACT stands for Accelerating CCS Technologies, and its aim is in the name – accelerate the development of CCS technologies. The collaboration began as an ERA-NET Cofund. This was an instrument of the EU’s Horizon Europe programme for research and innovation, where the European Commission would provide top-up financing for European countries collaborating on international joint calls for research and development on key topics. Many ERA-NET Cofunds were established across a broad range of topics, but ACT was the only ERA-NET Cofund relating to CCS.

33 research and innovation projects

Over the period 2016-2021, ACT carried out three calls for proposals giving R&D organisations and industry the opportunity to apply for funding for new CCS-related projects. These have resulted in 33 research and innovation projects with a total budget of NOK 1.4 billion, with ACT providing close to NOK 1 billion of that (close to € 1 M).

The projects supported by the first ACT call are now complete, while projects from the second call are now into their final year. 13 projects from the third ACT call are in their start-up phase. You can find details about the projects on the ACT website.

Norway has been a key pioneer of ACT, and Norwegian partners are involved in 23 of 33 projects. Financial support from ACT for Norwegian partners totals around NOK 230 million, with NOK 200 million coming from CLIMIT and roughly NOK 30 million coming from the European Commission. In other words, CLIMIT has been a key and major investor in ACT, and ACT projects account for around a fifth of CLIMITs total portfolio.

Solid results

ACT can boast five years of solid results. Importantly, ACT-supported projects have led to significant technology development in line with CLIMIT’s programme plan. New knowledge and expertise have been uncovered through ACT, and we have seen new and promising innovations in carbon capture, transport and storage. That said, the results and impacts of ACT go far beyond technological innovations:

- Thanks to ACT, many countries helped in financing the projects. Sharing costs like this means that each country gains more knowledge and expertise for each penny invested than would have been possible through national calls for proposals alone.

- ACT has helped coordinate research priorities across national borders.

- Thanks to ACT, many countries have invested much more in CCS research and innovation than they would have without ACT.

- ACT projects have proved attractive for industrial partners, helping mobilise industry.

- ACT projects have engaged in knowledge sharing activities that have given decision makers and industrial operators increased understanding of CCS.

- Both the ACT projects and the policy agencies behind ACT have facilitated fantastic knowledge sharing across national borders.

Just before Christmas, ACT presented their final report to the European Commission.

Many ACT projects have delivered results needed to construct large-scale CCS facilities. We have provided some examples below:

- The Pre-ACT project, coordinated by SINTEF, has examined how pressure build-up can be managed while storing CO2. This has led to new knowledge important for partners in the Northern Lights project.

- ELEGANCY, also coordinated by SINTEF, has examined how hydrogen value chains combined with CCS can be established. The results are vital now that hydrogen is an important priority for Norway and other countries.

- Many ongoing projects are examining monitoring technologies for CO2 storage sites. Large-scale storage sites will require accurate and cost-effective technologies that document how CO2 flows, so that we can ensure it is being stored safely. The projects DigiMon (coordinated by NORCE), SENSE (coordinated by NGI) and ACTOM (coordinated by the University of Bergen) are examining different monitoring technologies for storage sites.

- The NEWEST-CCUS project is researching new solutions for CO2 capture at waste management facilities. SINTEF and many Norwegian industrial operators from the waste management industry are involved in the project.

- The AC2OCEM project is developing new technology for CO2 capture at cement factories. SINTEF and NTNU are Norwegian partners. Many large industrial companies are involved in the project.

- A newly started project, RETURN, coordinated by SINTEF, will examine how empty oil and gas fields can be re-used for CO2

- Another new project, CEMENTEGRITY, coordinated by IFE, will research how cement can be used in CO2

All policy agencies involved in ACT are prepared to continue working together. One aim is to continue ACT through the EU’s new Clean Energy Transition Partnership (CETP), which is in its early phase as of spring 2022. Some countries involved in ACT are also planning an ACT4 call for proposals. This proposal will be available on the ACT website in April or May 2022.

Towards a new CO₂ deposit on the NCS

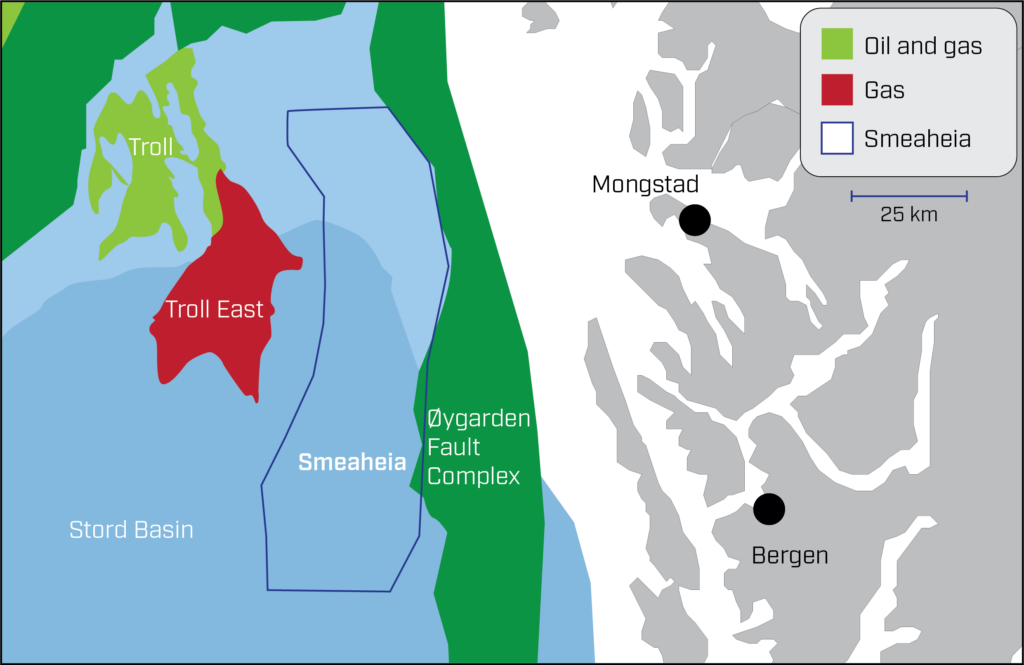

The SWAP and SWAP 2 projects confirmed that the CO2 storage capacity in the Smeaheia area is as significant as expected. Now Industry and researchers can present data that uphold previous estimates with higher confidence.

In the spring of 2018, Equinor was awarded a licence to drill an exploration well in the southern part of the Smeaheia area. The subsequent drilling on the Gladsheim structure during 2019, represented a rare opportunity to collect subsurface data, paving the way for a future CO2 repository. SWAP (Strategic Well Acquisition Project), supported financially by CLIMIT, was established in 2019 in order to gather data that operators usually do not collect when drilling exploration wells.

«The idea was that even if the well turned out to be dry, it would still be important to extract extensive data from the subsurface, since the area is a prospective CO2 storage location, explains Equinor’s Rune Thorsen, project manager for SWAP.

Comprehensive scope

A large part of the extra collection consisted of data from the cap rock. The data confirmed that the cap rock is strong and will remain impermeable if CO2 should be injected into the reservoir. Core samples were taken and rock-mechanical tests executed in order to find the quality and strength of the cap rock. Equinor also measured the porosity, permeability and fracture pressure of the rock in a thick shale, the Draupne formation. Usually, these types of samples of the cap rock are not taken in an exploration well.

In addition, a set of pressure measurements were conducted in the different reservoirs, in order to measure the degree of communication with the Troll field.

And the analyses yielded positive results

«It was confirmed that the reservoirs are well suited for CO2 sequestration. There is ample communication with the Troll field, and core samples extracted in the Gladsheim well confirms that the strength of the cap rock is good. This means that we can inject very large volumes of CO2,» says Thorsen.

In the SWAP 2 project, extra data was captured from another exploration drilling, this time at Stovegolvet, in the southern part of the Horda platform.

«When we exploration drill on the Horda platform around Troll, the chances of finding commercial quantities of hydrocarbons typically lie between 20–30 percent. But our long experience and understanding of the area tell us that the geology can safely retain CO2. If we collect comprehensive amounts of data during exploration drilling, we can avoid injecting only small volumes of CO2 initiallybefore ramping up volumes after several years of injection experience. Retrieving data during exploration drilling enables us to scale up volumes faster,» explains Thorsen.

A step closer to realization

And these are exciting times for the CCS community. In June 2021, Equinor nominated Smeaheia for licensing by the Norwegian Ministry of Petroleum and Energy. In September, the licensing round for the next significant areas for CO2 storage on the Norwegian Continental Shelf, was opened. And Equinor was one of the five companies that submitted bids.

«At Smeaheia, we have proposed developing a storage solution for 20 million tonnes of CO2 per year. This represents a formidable and necessary increase in global CO2 injection capacity and should be regarded as an explicit benefits realisation of the pioneering Norwegian Longship project » says Thorsen.

Equinor has ambitious plans to stay ahead as one of the global leaders in the field of CCS.

«We hope that we will be awarded the licence on Smeaheia, and that the second well at Stovegolvet can open up for further CO2 storage licenses in the area. I believe that the entire Horda platform – which includes the current Northern Lights licence, Stovegolvet, Smeaheia and the surrounding region – has the potential to become a huge central deposit area for CO2 on the NCS.»

Financial support from CLIMIT represented an important contribution to the project

«CLIMIT awarded financial support that made it possible to execute SWAP and SWAP 2. Without this support and results from drilling, CO2 sequestration on Smeaheia would probably have been delayed by several years,» says Rune Thorsen.

Partners in SWAP were Equinor and licence partners in PL921: Lundin Norge, Petoro and DNO Norge AS. Partners in SWAP2 were Equinor and license partner in PL785S, TotalEnergies.

Reducing the risks of CO₂ injection

Re-using old oil and gas fields as permanent storage sites for CO2 have many advantages – but also some challenges. The purpose of InjectWell is to obtain a better understanding of what happens in the well area when CO2 is injected into old hydrocarbon reservoirs.

The InjectWell project is a technical development study, headed by the Norwegian research institute, NORCE, in collaboration with partners from Germany, Wintershall Dea and the Technical University of Freiburg.

«The project delivers experimental and numerical understanding of well integrity and near-wellbore effects and phenomenon dedicated to CO2 injection into pressure depleted hydrocarbon reservoirs (DHR). In this project, we contribute to lower the threshold for re-using and storing CO2 in old oil and gas reservoirs by making the injection operation of CO2 more predictable and safer», says senior researcher and project manager Jonas Solbakken at NORCE.

Theory and practice

The methodology for improved understanding of injectivity and flow assurance well-to-reservoir relies on sound mathematical simulations and realistic experiments conducted in the laboratory. Experimental data and results can be used as input to tune and improve and the simulations, while the simulations may generate new insight that can be used to adjust and improve the experimental design and the generated datasets.

“From this project, both generic and specific knowledge and data will be produced, which should be relevant for the CCS research community and the industry. The specific cases will target and support ongoing projects of large-scale storage of CO2 in some old oil and gas fields in Europe.”

High degree of complexity

The project team seek to better understand what operational conditions can give constrains with respect to the planned CO2 injection rates. This is important to understand for large-scale storage projects to reach their targets with less hassle and downtime. There is, however, a plethora of complexity in the well area and possibilities that problems may occur – one of the reasons is because CO2 doesn’t behave like many other gases.

«When compressed CO2 is pumped at high velocity down a deep well and into a reservoir, the properties of the CO2 may change a lot. In the case of pressure depleted reservoirs, significant differences in pressure and temperature conditions may be exposed to the CO2 during its pathway through the well and into the reservoir. This increases the complexity of the actual processes going on in such operations and this could give implications on injectivity, which we need to understand better», says Solbakken.

Depleted hydrocarbon reservoirs versus saline formations

CO2 can be stored in different geological settings. The InjectWell develops reference experiments and simulations that can be used to shed light on the differences between CO2 injection in depleted oil and gas reservoirs and saline water formations.

«A broader understanding of possible bottlenecks and advantages/disadvantages related to CO2 injection into depleted reservoirs compared to saline formations, should be valuable knowledge in the development of new concepts for CO2 storage also on the Norwegian Continental Shelf», says Solbakken.

Suitable software

Furthermore, the researchers in collaboration with the industrial partner, intend to test and compare various versions of commercial simulation software for CO2 injection.

Currently, the oil industry utilizes different software for simulation of processes in the well, near-well area and the reservoir. However, these tools still lack several dedicated functionalities for injection and storage of large volumes of CO2.

«We want to understand how well the simulators on the market today perform, when it comes to describing the various processes and phenomena in the wellbore and near-wellbore area, under realistic scenarios of CO2 injection», explains senior researcher Nematollah Zamani at NORCE.

«NORCE is a leading institute within research and development of dedicated simulation tools for CO2 storage. Currently, several research groups at NORCE are working on this topic. In the InjectWell project, NORCE will primarily lead and deliver experimental-based-research using their experimental capacities. Laboratory derived parameters and datasets, particularly, at field-realistic conditions are challenging to perform but crucial to improve understanding and feasibility of subsurface processes, including a major contribution to calibrate, verify and increase accuracy of simulator software and models for CO2 storage. The ambition is that future simulators can be used with better precision and robustness in this specific field», says Solbakken.

Support from CLIMIT

The total budget of InjectWell is 14 MNOK. 6.3 MNOK is covered by the industrial partner, while MNOK 7.7 is supported by the CLIMIT Program.

Moreover, CLIMIT has also an important role in connecting relevant projects and partners, and thus, facilitate knowledge transfer and synergies to accelerate realization of more full-scale CCS applications. Already early in the project, the researchers were contacted by interested parties who had read about the InjectWell project or was encouraged by CLIMIT to contact the project manager, or the NORCE organization.

“CLIMIT has a very good overview of the field of CCS. CLIMIT fulfils an important function in aligning the research communities with the needs of industrial players. A closer collaboration between research and industry is definitely a win-win situation”, says Solbakken.

Bacteria shown to help in ensuring safe carbon storage

When storing CO2 deep underground, we need to be certain that this greenhouse gas stays put. Researchers at NORCE have shown that bacteria can lead to the formation of solid precipitates that block off potential points of leakage. These results will be useful for the development of future storage sites.

Bacteria seals

Svenn Tveit, project manager at NORCE, has led a team of researchers who have been studying a unique concept that would result in secure carbon storage deep under the earth. Large-scale, high-pressure CO2 injection into geological formations can create fractures that allow the CO2 to find its way back to the surface. In order to prevent this, special bacteria can be employed that produce a solid compound, which seals the fractures. Tveit and his team have studied this phenomenon in a CLIMIT-financed R&D project.

It is well-known that certain bacteria can produce calcite, a solid and non-porous compound. Tveit and his colleagues have studied how this mechanism can be exploited at carbon storage sites.

‘Our conclusion is that bacterial calcite precipitation can ensure secure carbon storage. The predictability of this technology requires accurate simulation models; however, this is something we’ve developed during the project,’ says Tveit.

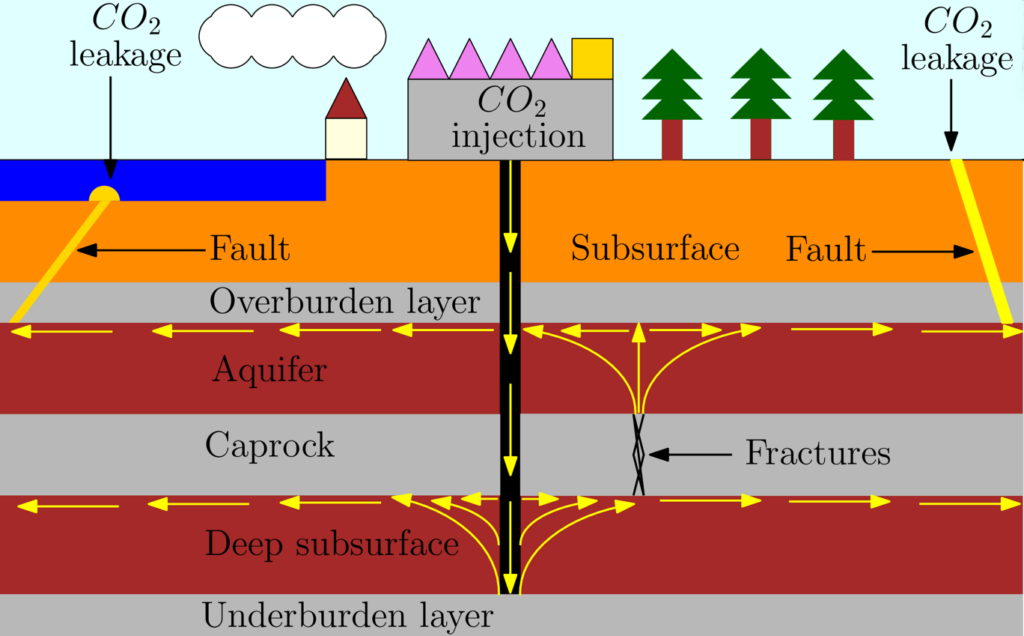

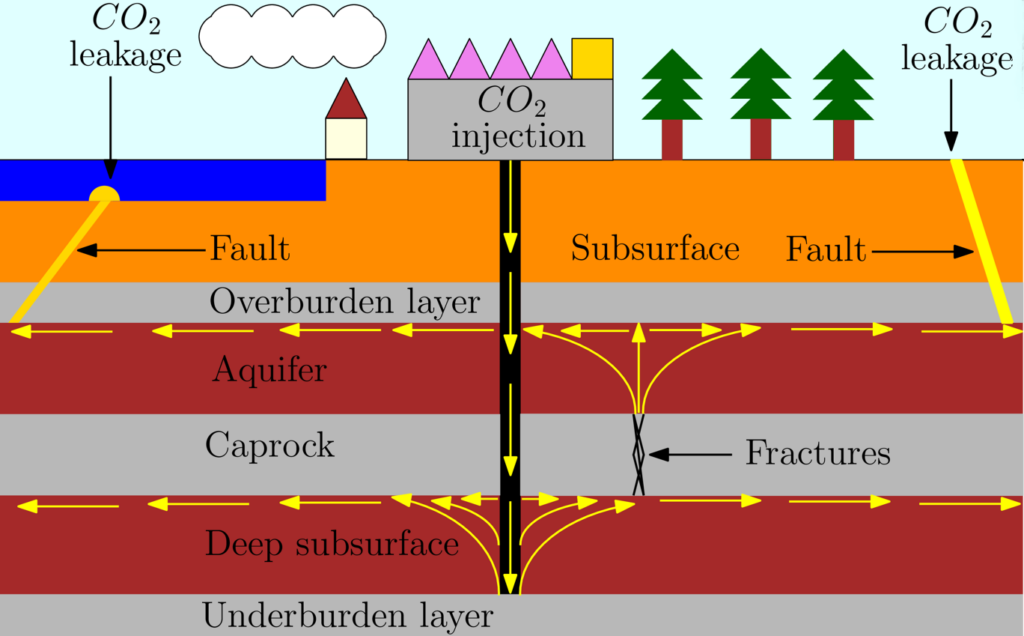

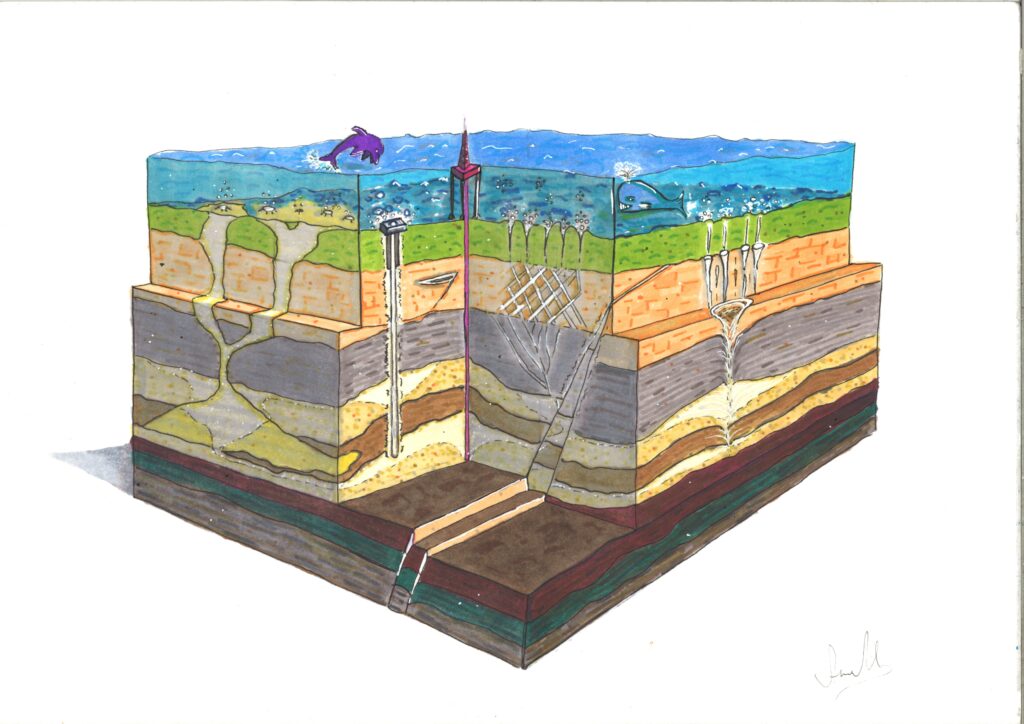

The image below illustrates how CO2 stored deep underground can move through fractures and potentially end up either in the ocean or the atmosphere. The important thing is to seal the fractures so that CO2 cannot escape.

CO2 is stored in the deep subsurface layer. Sealed caprocks will prevent CO2 from escaping from the storage site, but CO2 can still move through faults and fractures. Illustration: NORCE

Promising injection strategies for effective calcite precipitation

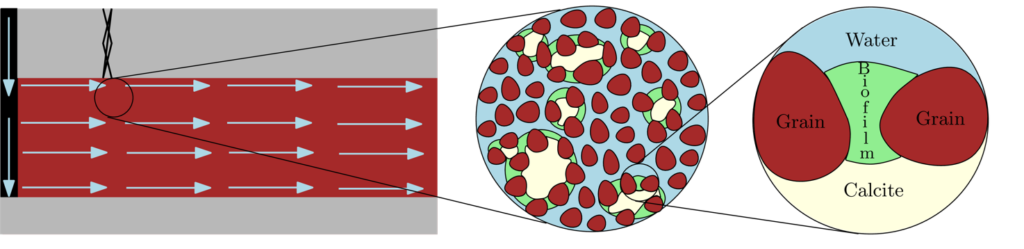

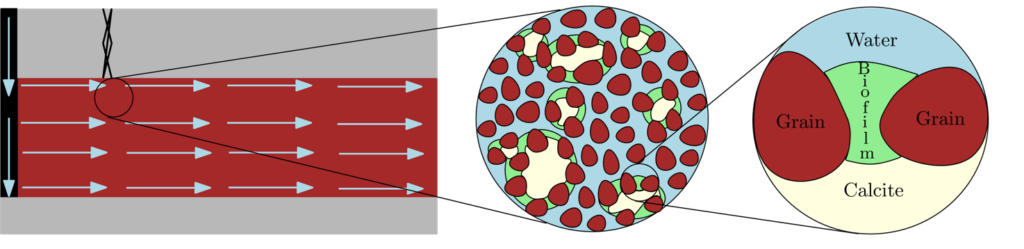

During the project, Tveit found evidence that bacteria can be cultivated to produce a biofilm that covers fractures in the rock. This can then produce calcite precipitation, which will completely seal the fracture as shown in the illustration below.

In porous rocks, there is empty space where water or CO2 can travel freely. Bacteria can act as biofilm which produces calcite precipitate. This seals the fractures so that CO2 cannot escape from the storage site. Illustration: NORCE.

This method is called microbially induced calcite precipitation, and, to get it to work, it is important to develop a strategy to inject microbes and other components that will allow the top of the formation to be sealed, while still allowing CO2 to be injected further below.

Current models need to be scaled up to tackle these problems. It is well-known that, if improperly scaled-up, using bacterial and chemical reactions in underground flow models can lead to major errors.

‘Over the project, we developed models for upscaling and established promising injection strategies for efficient calcite precipitation,’ underscores Tveit.

Their mathematic model has been implemented in an open-source simulator called OPM Flow so that it can be used and further developed in academic and industrial environments.

A significant number of carbon storage sites are needed to achieve international climate goals. These new results on calcite precipitation will be extremely useful for those businesses that will go on to develop and operate all these storage sites.

Key data about the project

Title: MICAP – Efficient models for Microbially Induced Calcite Precipitation as a seal for CO2 storage

Project number: 268390

Partners: NORCE (project owner), University of Bergen, University of Stuttgart, Tufts University, Wintershall AS

Project period: 2017-2021

Budget: NOK 9 million. Funded in its entirety by the Research Council of Norway

Sharing CCS datasets with R&D communities across the globe

Since October 2017, CLIMIT and the US Department of Energy have been supporting the ‘CO2 DataShare’ project. An important project focused on sharing experience and key information relevant for upcoming CCS projects.

This is a joint project between SINTEF, the University of Illinois, Equinor and the IEAGHG.

A digital platform featuring quality-assured datasets

CO2 DataShare will allow users access to documented datasets with the specific aim of supporting research and development. During this first phase, the project has targeted carbon storage data but proposes to explore the possibility of sharing data from other stages of the CCS value chain. It is anticipated that data sharing from pilot, demonstration and industry projects will strengthen the R&D communities’ ability to develop new knowledge and technology and thus, help upcoming full-scale projects to reduce their costs, improve efficiency and be even safer.

The platform is not intended to be a repository for large amounts of data, but rather a tool for supporting targeted research. The project serves as a meeting point for international knowledge exchange and cooperation, enabling dialogue through user fora and webinars. A code is used to identify each dataset (Digital Object Identifier, DOI), making it easy to refer to data and for other researchers to find and use datasets.

Grethe Tangen, the project manager at SINTEF, emphasises that a major milestone of the project is the implementation of the digital framework for sharing data from CCS projects. So far, the project has published datasets from the Sleipner and the Smeaheia CO2 storage projects. A dataset from the Illinois Basin – Decatur Project in the United States will be published in the near future. The project has also demonstrated that there is significant interest in data sharing. Over 330 different organisations from more than 50 countries have downloaded data from the site.

‘My predecessor, Svein Eggen, was a major proponent of this project and was instrumental in getting it started,’ says Kari-Lise Rørvik, Senior Advisor at Gassnova. It is especially gratifying that Gassnova has contributed with own data from the work on the Smeaheia CO2 storage prospect. We are very interested in the outcomes of this project, and it aligns perfectly with what Gassnova should bring to the table – sharing our knowledge,’ she continues.

Strengthening international cooperation

CO2DataShare started as a joint initiative between Norwegian and American stakeholders from industry, research, and public authorities to ensure standard procedures for data processing, efficient data exchange, and quality-assured data usage. The project has been a success, and further developments are now possible.

‘We are currently in dialogue with Accelerating CCS Technologies (ACT) about the possibility of using CO2 DataShare to share data from research projects. 17 February we are organising a workshop with representatives from the different ACT projects to explore this,’ Grethe Tangen concludes.

ACT-CO₂DataShare Webinar

We are delighted to invite you to an information webinar 17 February 2022. This is a follow up of the dialogue between the ACT consortium members and CO2 Datashare.

Agenda – 17 February 2022 15.00 GMT

Introduction; James Craig, IEAGHG

Short recap of CO2DataShare; Grethe Tangen, SINTEF

- The portal, datasets published, types of data, what does it take to share data.

Value of sharing data; Darin Damiani, US Department of Energy

- Strengthening research and development through data sharing

- ACT – CO2DataShare opportunity for collaboration

Value for data owners;

- Remarks from Philip Ringrose, Equinor, and Sallie Greenberg, University of Illinois.

Q/A – discussion

While the concept paper you received from Ragnhild provided some details about the CO2 DataShare platform and the potential value of your participation, we expect you’ll want to understand better what this is all about. Therefore, we invite you to this ACT-CO2DataShare webinar to provide you greater detail. In the webinar we will present what CO2 DataShare is, what we mean by “data”, and why we think the curation of data for sharing to the international community of CCS stakeholders has great value. You will also hear from data owners who are currently sharing their data on CO2 DataShare. And we will wrap up the webinar leaving time for your questions.

As Ragnhild pointed out, participation in CO2 DataShare is voluntary. The aim of this webinar is to better inform you on the CO2 DataShare concept and invite those who are interested to continue a dialog with us on how to participate. Feel free to forward this invitation if there are others that will coordinate the project.

CO2 DataShare is not intended to be a simple repository of project data. Our quest is to curate selected high-value, high quality datasets for sharing globally with other researchers and stakeholders. What we seek is the opportunity to discuss with you the data your project has or will be generating and if these data meet that criteria from YOUR perspective. The choice to share these data will be yours. What we are offering is a highly visible data sharing portal that provides ease of access to quality datasets, which collectively will facilitate and expand upon the trend in data digitalization that is serving to accelerate the global clean energy transition.

CLIMIT has a new programme plan!

The programme plan sets out CLIMIT’s goals and focus areas. All projects supported by CLIMIT must meet the programme plan’s goals and priorities. Therefore, the programme plan is extremely important for all those who have an exciting project and are hoping to apply for support from CLIMIT.

Applications must meet one or more of the priorities in the programme plan

We have made a new programme plan that is very similar to the previous one. But we have updated several areas of the plan. The most important updates are:

- Clear emphasis on the fact that CLIMIT should support the realisation of gains of Longship

- A new focus area is the decarbonisation of industrial and energy resources

- Hydrogen production, combined with CCS is a top priority

- Increased focus on direct air capture and bioenergy combined with CCS.

- A clearer position of social scientific research

In all future CLIMIT announcements, there will be a provision that applications must meet one or more of the priorities in the programme plan.

A CLIMIT supported project has yielded such promising results that Hydro will invest in the technology

The project’s goal is to develop an alternative process to produce aluminium from aluminium oxide that may result in lower CO2 emissions than the current well-established electrolysis process (Hall-Heroult process).

Text and photo: Hydro

In launching its new sustainability ambitions, Hydro has announced its intention to deliver its first commercial volumes of near-zero carbon aluminium in 2022. Hydro is also continuing its technology efforts toward an industrial scale pilot producing carbon-free aluminium by 2030.

Without CO2 emissions

In Norway, more than two million tonnes of CO2 per year are emitted from the electrolysis plants. Globally, more than hundred million tonnes are emitted. CO2 stems from the reaction between aluminium oxide and carbon anodes. During the electrolysis process, aluminum oxide is split into liquid aluminium metal on the cathode and CO2 is on the anode. In the alternative process, aluminium oxide is first converted to anhydrous aluminum chloride, AlCl3, which is then electrolysed. In this electrolysis process, aluminium chloride is split into liquid metal on the cathode and chlorine gas on the anode. The electrolysis process itself takes place without CO2 emissions. Anhydrous aluminum chloride does not exist naturally and must be made as an integral part of the process.

On a large scale, the only proven method is so-called carbochlorination of aluminium oxide at around 700°C: Al2O3(s) + 1.5C(s) + 3Cl2(g) = 2AlCl3(g) + 1.5CO2(g). Chlorine for this reaction will come from the electrolysis of AlCl3. Even if CO2 is not formed in the electrolysis process itself, CO2 will form during carbochlorination. But this CO2 can be captured far more easily than the one from the current electrolysis process since it is almost concentrated. It is also possible to recycle it in this process. It is known that CO gas can be used instead of carbon to produce AlCl3. CO2 from the carbochlorination can therefore be converted to CO and thus recycled. For example, conversion of CO2 to CO can occur using hydrogen or electrolysis. Alternatively, CO can be made from natural gas with hydrogen as a by-product. Then CO2 from production of AlCl3 must be sent to storage (CCU). An additional option is to use biomass to make CO. Then produced CO2 could be released to the atmosphere climate neutral or, if stored, give net capture of CO2. All these options will be evaluated in the project. In addition, the carbochlorination process will be studied in depth and a techno-economic model will be developed for the whole process.

Crucial to understand how CO₂ moves in a reservoir

Researchers at the Institute for Energy Technology (IFE) have been studying how sequestered carbon dioxide moves through so-called chimneys in rocks, providing new knowledge about how CO2 can be safely stored in geological formations.

Stored safely for years

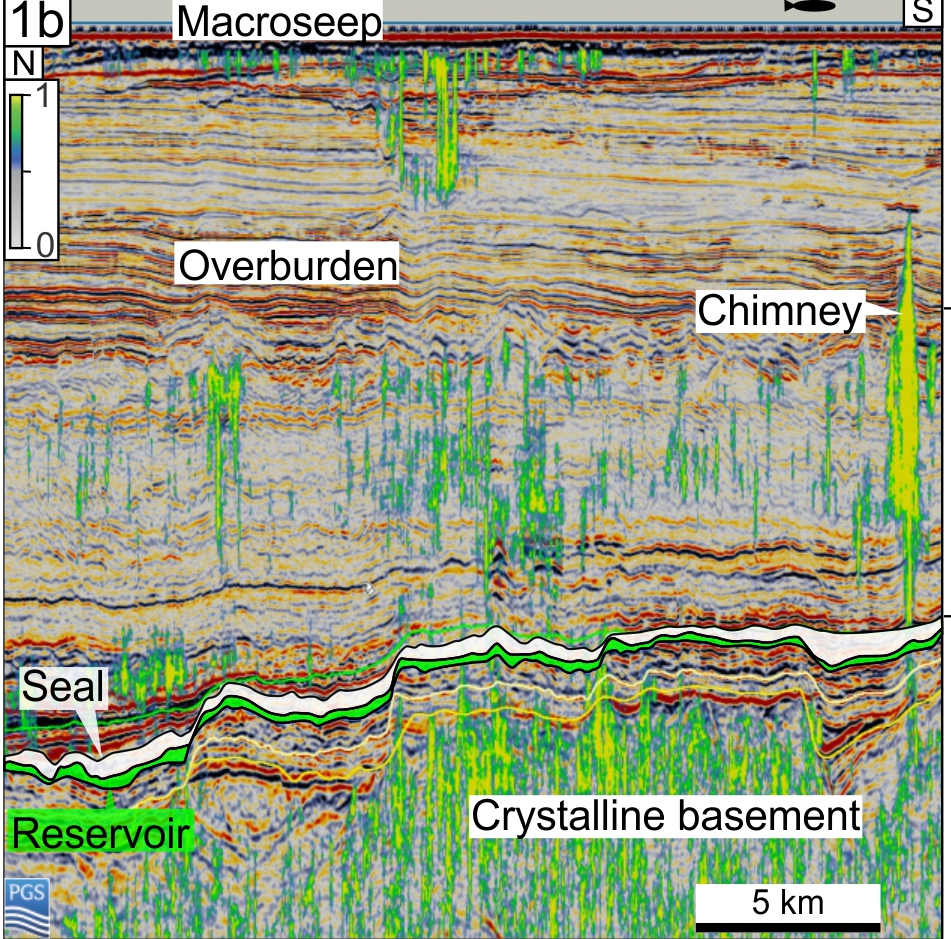

Carbon dioxide has been stored safely in the Utsira Formation in the North Sea for years. The formation contains a number of vertical structures called chimneys that allow CO2 to flow between the different sedimentary layers. Chimneys have also been observed in the sealing layer of the cap-rock above the Utsira aquifer. Utsira is a safe site for storage of CO2, but in order to find new, safe storage locations, it is important to understand how these chimney structures are formed and behave.

Chimneys are explained in the figure below. The rock deep below the seabed is made up of many horizontal sedimentary layers. Chimneys are vertical channels that connect the various sedimentary layers. Liquids can, in principle, move through the chimneys and thus move from one layer to another.

All CO2 remains in place

Although chimneys have been observed in the sealing cap-rock layer above the Utsira aquifer, there is nothing that indicates that CO2 is moving out of the storage site. All the CO2 that has been injected into the Utsira Formation stays where it should be.

The figure below shows that chimney structures are common in close to impermeable sedimentary layers.

Important to understand the structure of chimneys

The Utsira CO2 reservoir is tight, but in connection with developing new sequestration sites, it is important to fully understand chimneys so that we can be sure that new storage sites also remain tight.

In the CO2-PATHS project, researchers from the Institute for Energy Technology (IFE) and the Norwegian Institute for Water Research (NIVA) have studied these chimney structures in detail. The researchers have created physical models to determine how chimneys are formed and how they behave. Project manager Magnus Wangen says this has generated important new knowledge.

“We have concluded that chimneys have such low permeability that they will cause negligible CO2 flow from a reservoir. However, to ensure safe storage, it is necessary to monitor chimneys located above or near CO2 reservoirs,” Wangen points out.

New understanding

The chimneys that are visible today were formed way back in geological time by high fluid pressure. Reservoir fluids can move in the chimneys, and the lightest components will move upwards. In the project, the researchers studied how glacial processes created high pore pressure in sedimentary layers in the Utsira aquifer. This has provided new understanding of how fluids move in chimneys. The project has had a particular focus on whether chimneys can form in the cap-rock that prevents CO2 from flowing out into the sea. The researchers have built models for pressure build-up caused by glacial loading and have studied how viscous deformations can form chimneys in sedimentary basins.

CO2-PATHS’ new physical models will be useful for researchers and operators of CO2 storage sites.

“The knowledge generated in CO2-PATHS will be very useful when assessing new storage sites. We now know more about chimneys, and this has increased our understanding of how CO2 might move in new storage sites,” says Wangen.

The results of the project have been published in a series of scientific articles in internationally recognised journals.

Key data about the project

- Title: CO2-PATHS – Prediction of CO2 leakage from reservoirs during large scale storage

- Project number: 280567

- Partners: The Institute for Energy Technology (IFE) (project owner) and the Norwegian Institute for Water Research (NIVA)

- Project period: 2018–2021

- Budget: NOK 8.2 million. Funded in its entirety by the Research Council of Norway